High-oxygen-index automotive trim PVC (polyvinyl chloride) composite fabric prepared by blade-coating method and preparation method thereof

An automotive interior, high oxygen index technology, applied in the field of artificial leather, can solve problems such as the formula of PVC composite fabrics, the viscosity of PVC paste is increased, and the process cannot be carried out, so as to inhibit the formation of toxic gases and smoke, and achieve flame retardancy. The effect of improving the performance and reducing the burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

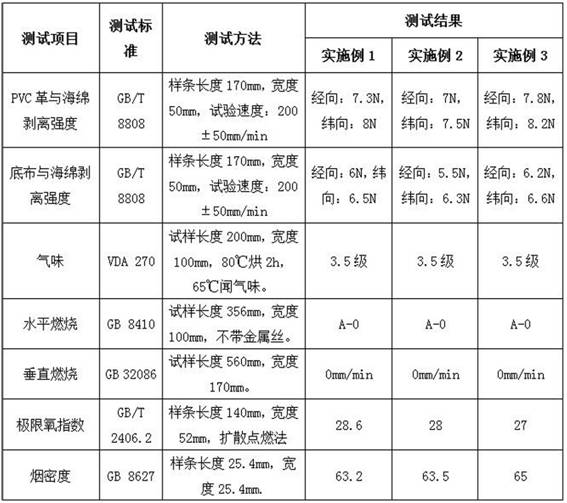

Embodiment 1

[0031] The surface layer slurry is obtained in the following proportions by weight: 100 parts of PVC paste resin, 15 parts of plasticizer DPHP, 50 parts of tetrabromophthalic anhydride ester, 25 parts of phosphoric acid ester, 25 parts of antimony trioxide, 10 parts of magnesium hydroxide, 5 parts of aluminum hydroxide, 10 parts of silicone, 3 parts of heat stabilizer, 5 parts of color paste, and the viscosity of the surface layer slurry is 10000mPa.s;

[0032] The foaming layer slurry was obtained according to the following proportions by weight: 100 parts of PVC paste resin, 15 parts of plasticizer DPHP, 50 parts of tetrabromophthalic anhydride ester, 25 parts of phosphoric acid ester, 25 parts of antimony trioxide, and 10 parts of magnesium hydroxide , 5 parts of aluminum hydroxide, 10 parts of organic silicon, 3 parts of heat stabilizer, 5 parts of color paste, 2 parts of foaming agent, and the viscosity of foam layer slurry is 10000mPa.s;

[0033] Among them, the phosphat...

Embodiment 2

[0037] The surface layer slurry is obtained in the following proportions by weight: 100 parts of PVC paste resin, 25 parts of plasticizer DPHP, 40 parts of tetrabromophthalic anhydride ester, 15 parts of phosphoric acid ester, 15 parts of antimony trioxide, and 5 parts of magnesium hydroxide , 2 parts of aluminum hydroxide, 5 parts of silicone, 5 parts of heat stabilizer, 8 parts of color paste, and the viscosity of the surface layer slurry is 7000mPa.s;

[0038] The foam layer slurry was obtained in the following proportions by weight: 100 parts of PVC paste resin, 25 parts of plasticizer DPHP, 40 parts of tetrabromophthalic anhydride ester, 15 parts of phosphoric acid ester, 15 parts of antimony trioxide, 5 parts of magnesium hydroxide 2 parts, aluminum hydroxide 2 parts, silicone 5 parts, heat stabilizer 5 parts, color paste 8 parts, foaming agent 2 parts, foam layer slurry viscosity 7000mPa.s;

[0039] Among them, the phosphate ester mentioned in the above-mentioned surfac...

Embodiment 3

[0043] The surface layer slurry is obtained in the following proportions by weight: 100 parts of PVC paste resin, 20 parts of plasticizer DPHP, 30 parts of tetrabromophthalic anhydride ester, 20 parts of phosphoric acid ester, 20 parts of antimony trioxide, and 7.5 parts of magnesium hydroxide , 3.5 parts of aluminum hydroxide, 3.5 parts of organic silicon, 4 parts of heat stabilizer, 7.5 parts of color paste, and the viscosity of surface layer slurry is 8500mPa.s;

[0044] The foam layer slurry was obtained according to the following proportions by weight: 100 parts of PVC paste resin, 20 parts of plasticizer DPHP, 30 parts of tetrabromophthalic anhydride ester, 20 parts of phosphoric acid ester, 20 parts of antimony trioxide, 7.5 parts of magnesium hydroxide 3.5 parts of aluminum hydroxide, 3.5 parts of organic silicon, 4 parts of heat stabilizer, 7.5 parts of color paste, 2 parts of foaming agent, and the viscosity of foam layer slurry is 85000mPa.s;

[0045] Among them, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com