Preparation method and application of multivariate cooperation flame-retardant polyol

A flame-retardant polyol and synergistic flame-retardant technology, which is applied in the fields of chemical industry, energy conservation and protection, and environmentally friendly new technology, can solve the problems of physical and physical performance reduction, reduction of polyurethane physical and mechanical properties, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

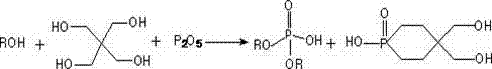

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not only limited to embodiment, and the change that the professional of this field makes to technical solution of the present invention all should belong in protection scope of the present invention.

[0027] 1. A preparation method of multiple synergistic flame retardant polyols

[0028] Add 75g of mixed alcohol to the reaction kettle, the mixed alcohol is composed of 25g of pentaerythritol and 50g of methanol; heat to reflux for 1.5h, continue to add 150g of phosphorus pentoxide, the temperature rises to 70°C, and keep it warm for 3h to obtain a phosphorus ring flame retardant intermediate Continue to add 4g of catalyst tetraethylammonium bromide, raise the temperature to 120°C, add 250g of epichlorohydrin; react for 2 hours, add 80g of tetrabromophthalic anhydride, evacuate the reaction until no water is distilled out, and cool to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com