Method for preparing structure type flame-retardant castor-oil-based polyester polyol and applications thereof

A polyester polyol, castor oil-based technology, applied in the preparation of structural flame-retardant castor oil-based polyester polyol and its application field, can solve the difficulties in the synthesis of tribromostyrene, harsh reaction conditions, and corrosion of foaming equipment In order to achieve the effects of low cost, low smoke density and improved flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

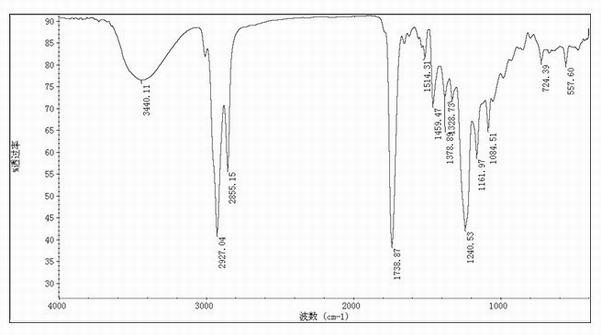

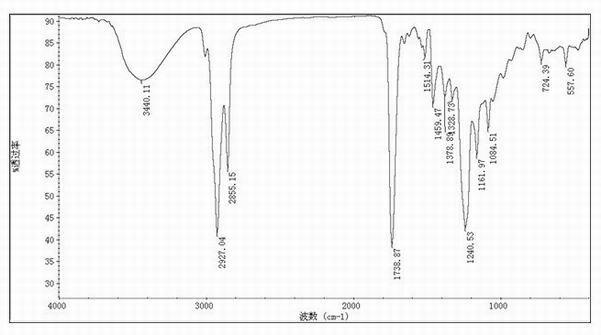

Image

Examples

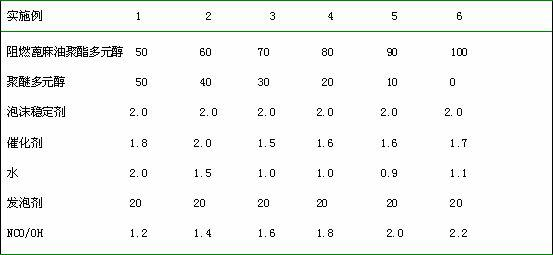

Embodiment 1

[0042] Embodiment 1: put 100g castor oil into the reactor, carry out alcoholysis reaction with 20g glycerol, catalyst calcium hydroxide 1g, reaction temperature is 200 ℃, keep warm for 1h, heat up to 220 ℃ keep warm for 2 hours. Gradually lower the temperature to 150°C, add 70g of tetrabromophthalic anhydride and 0.5g of tetrabutyl titanate, control the outlet water temperature to less than 100°C, slowly continue to heat up to 220°C, and then continue to react at 220-240°C for 4 hours. When the temperature is about 10 mg / g, cool down to 180°C, vacuumize, gradually increase the vacuum degree to 95 kPa, and vacuumize for about 1 h to end the reaction. The acid value of the obtained product was 1.0 mg / g KOH, the hydroxyl value was 340 mgKOH / g, the content of bromine in the product was 25 wt%, and the appearance of the product was a viscous brown-yellow liquid. Then obtain the combined polyol according to the preparation formula of rigid polyurethane foam in Table 1, stir at high ...

Embodiment 2

[0043] Example 2: Put 100g of castor oil into a reactor, carry out alcoholysis reaction with 35g of pentaerythritol, catalyst sodium methoxide 1g, reaction temperature is 180°C, keep warm for 1h, heat up to 230°C and keep warm for 2 hours. Gradually lower the temperature to 160°C, add 50g of tetrabromophthalic anhydride and 0.6g of tetraisopropyl titanate, control the outlet water temperature to less than 100°C, slowly continue to heat up to 220°C, and then continue to react at 220-240°C for 5 hours, when the acid value When the temperature is about 10 mg / g, cool down to 180°C, vacuumize, gradually increase the vacuum degree to 95 kPa, and vacuumize for about 2 h to end the reaction. The acid value of the obtained product is 0.8mg / g KOH, the hydroxyl value is 420mgKOH / g, the content of bromine in the product is 20wt%, and the appearance of the product is viscous brown-yellow liquid. Then obtain the combined polyol according to the preparation formula of rigid polyurethane foam...

Embodiment 3

[0044] Example 3: Put 100g castor oil into the reactor, carry out alcoholysis reaction with 50g trimethylolpropane, catalyst zinc oxide 2g, reaction temperature is 210°C, keep warm for 4h, heat up to 240°C and keep warm for 2 hours. Gradually lower the temperature to 170°C, add 90g of tetrabromophthalic anhydride and 1.0 g of p-toluenesulfonic acid, control the outlet water temperature to less than 100°C, slowly continue to heat up to 220°C, and then continue to react at 220-240°C for 5 hours, when the acid value is 10 When the concentration is about mg / g, cool down to 180°C, vacuumize, gradually increase the vacuum to 95 kPa, and vacuumize for about 1 h to end the reaction. The acid value of the obtained product was 1.2mg / g KOH, the hydroxyl value was 230mgKOH / g, the content of bromine in the product was 28wt%, and the appearance of the product was viscous brown-yellow liquid. Then obtain the combined polyol according to the preparation formula of rigid polyurethane foam in T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com