Production method of flame-retardant unsaturated polyester

A technology of unsaturated polyester, applied in the field of preparation of flame retardant unsaturated polyester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

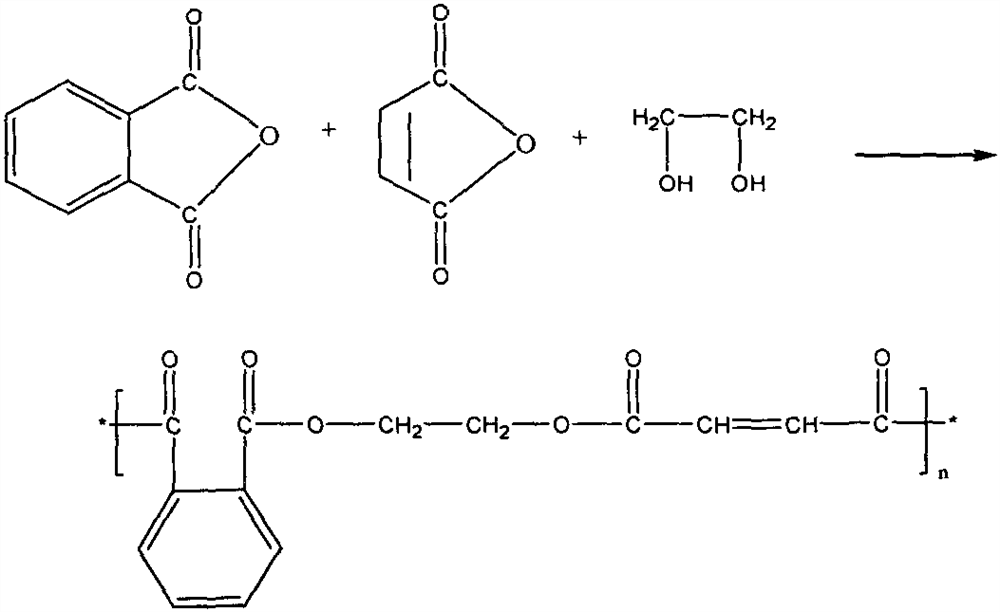

Image

Examples

Embodiment 1

[0019] Add maleic anhydride, phthalic acid, and ethylene glycol into a 250ml three-necked flask according to the ratio of 33:48:46, turn on the temperature-regulating heating mantle and start to heat slowly, and at the same time, pass cooling water into the straight condenser tube, Raise the temperature to 80°C within 15 minutes, stir thoroughly, then raise the temperature to 160°C in 45 minutes, then raise the temperature to 190-200°C within one hour, and maintain the reaction at this temperature for 10 minutes (during this period, use a separate The amount of water produced by the water tank), then stop heating and naturally cool to 100-110°C, then add 40g of styrene and start stirring, keep the temperature at 100-110°C for one hour, stop heating, naturally cool to 50°C, and then pour out the product. Yield 96%.

Embodiment 2

[0021] Take out 100g of unsaturated polyester, pour it into a beaker together with 0.5% benzoyl peroxide, heat and stir with a magnetic stirrer for a period of time, then add 0.1% accelerator tin dichloride, continue to stir, 2min, quickly Pour the viscous liquid into the mold and take it out after it solidifies. Its limiting oxygen index was tested to be 35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com