Heating cigarette core material and preparation method thereof

A core material and cigarette technology, applied in the field of tobacco products, can solve the problems of difficult thickness control, easy breakage, breakage, and small effective load dry matter, so as to improve the sense of thickness and satisfaction of smoking, and ensure stability and adaptability. The effect of good performance and adaptability to the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

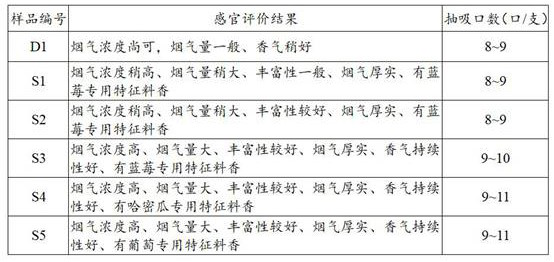

Examples

Embodiment 1

[0039] A heated cigarette core material and its preparation method, comprising the following parts (by mass): 40 parts of water-extracted tobacco paste and alcohol-extracted tobacco paste are weighed at a ratio of 2:5, and tobacco powder and stem powder are weighed at a ratio of 1:1 10 parts, 5 parts of general fragrance (moss extract), 0 parts of special characteristic fragrance, 2 parts of glycerol triacetate, 10 parts of glycerin and propylene glycol in the fuming agent weighed at a ratio of 5:1 and 3 parts of additives. Wherein, the additives include 2 parts of guar gum and 1 part of potassium carbonate.

[0040] The preparation method of the heated cigarette core material comprises the following steps:

[0041] Step (1): Mix the water-extracted tobacco paste and the alcohol-extracted tobacco paste in a ratio of 2:5, and weigh 40 parts to form tobacco extract.

[0042] Step (2): Drying, pulverizing and sieving the shredded tobacco flakes, shredded tobacco powder, and shre...

Embodiment 2

[0049] A heated cigarette core material and its preparation method, comprising the following parts (by mass): 40 parts of water-extracted tobacco paste and alcohol-extracted tobacco paste are weighed at a ratio of 2:5, and tobacco powder and stem powder are weighed at a ratio of 1:1 10 parts, 5 parts of general flavor (moss extract), 3 parts of blueberry-flavored special flavor, 2 parts of glycerol triacetate, 10 parts of glycerin and propylene glycol in fuming agent weighed at 5:1 and 3 parts of auxiliary agent. Wherein, the additives include 2 parts of guar gum and 1 part of potassium carbonate.

[0050] The preparation method of the heated cigarette core material comprises the following steps:

[0051] Step (1): Mix the water-extracted tobacco paste and the alcohol-extracted tobacco paste in a ratio of 2:5, and weigh 40 parts to form tobacco extract.

[0052] Step (2): Drying, pulverizing and sieving the shredded tobacco flakes, shredded tobacco powder, and shredded tobacc...

Embodiment 3

[0059] A heated cigarette core material and its preparation method, including the following parts (by mass): 45 parts of water-extracted tobacco paste and alcohol-extracted tobacco paste are weighed at a ratio of 2:5, and tobacco powder and stem powder are weighed at a ratio of 1:1 15 parts, 6 parts of general flavor (moss extract), 7 parts of blueberry-flavored special flavor, 2 parts of glycerol triacetate, 15 parts of glycerin and propylene glycol in fuming agent weighed at a ratio of 5:1 and 4 parts of additives. Wherein, the additives include 2.5 parts of guar gum and 1.5 parts of potassium carbonate.

[0060] The preparation method of the heated cigarette core material comprises the following steps:

[0061] Step (1): Mix water-extracted tobacco paste and alcohol-extracted tobacco paste in a ratio of 2:5, and weigh 45 parts to form tobacco extract.

[0062] Step (2): Drying, pulverizing and sieving the shredded tobacco flakes, shredded tobacco powder, and shredded tobac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com