Preparation method and application of high flexible reconstituted tobacco

A high-flexibility technology for reconstituted tobacco leaves, which is applied in the field of reconstituted tobacco leaves by papermaking, can solve the problems of difficulty in ensuring uniform dispersion, unstable product quality, and large quantity of extracts, and achieve low processing costs, outstanding characteristic style, and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

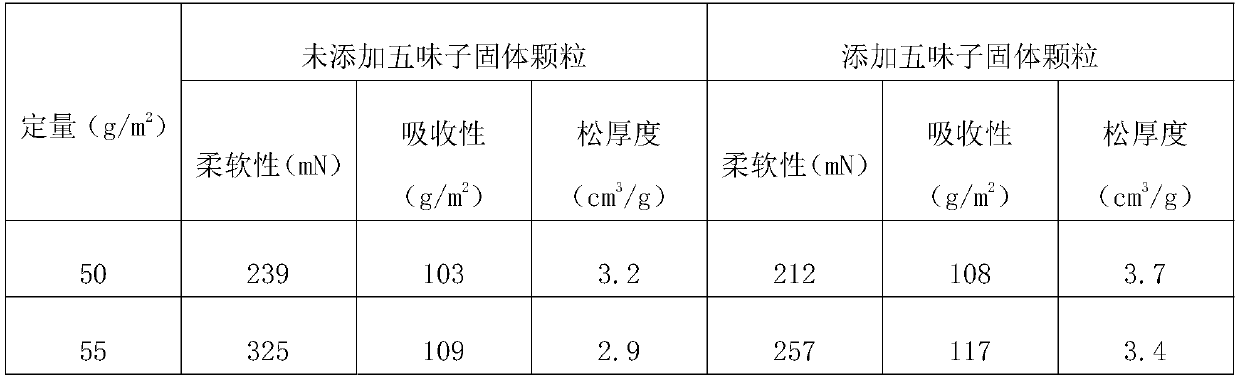

[0020] Return the extracted solid particles of Schisandra chinensis 2 The base of reconstituted tobacco leaves was quantified, and the physical indicators were compared with those of the base of reconstituted tobacco leaves without adding solid particles.

[0021] Table 1 Basic physical indicators of reconstituted tobacco leaves

[0022]

[0023] It can be seen from Table 1 that the physical properties of the film base added with Schisandra solid particles, such as softness, absorbency, and bulk, have been greatly improved, which shows that the solid particles of Schisandra chinensis (about 40-80 mesh in particle size) were copied into tablets. In the base, the base can be made loose and porous, and the porosity can be increased.

Embodiment 2

[0025] (1) The air-dried fruit of Schisandra chinensis after removing the core and impurities, after the Schisandra chinensis is crushed and sieved, the parts <100 mesh, 100-300 mesh, and larger than 300 mesh are collected respectively.

[0026] (2) Extract the Schisandra chinensis powder of less than 100 mesh and greater than 300 mesh, the extraction conditions are: solvent: 95% ethanol, temperature: 70°C, time: 60min / time, twice in total. After the solid-liquid separation of the extraction, the extract is left to settle, and the supernatant is collected for concentration to a density of 1.10g / cm 3 The paste is ready for use, and the solid obtained after solid-liquid separation is returned to the reconstituted tobacco leaf production process to produce reconstituted tobacco leaf base and coating liquid for use.

[0027] (3) Schisandra chinensis powder with a particle size of 100-300 mesh in step (1) is uniformly mixed with the coating liquid in the production of reconstituted t...

Embodiment 3

[0030] (1) The air-dried fruit of Schisandra chinensis after removing the core and impurities, after the Schisandra chinensis is crushed and sieved, the parts <100 mesh, 100-300 mesh, and larger than 300 mesh are collected respectively.

[0031] (2) Extract the schisandra powder of less than 100 mesh and greater than 300 mesh, the extraction conditions are: solvent: 50% ethanol, temperature: 40°C, time: 60min / time, twice in total. After the solid-liquid separation of the extraction, the extract is left to settle, and the supernatant is collected for concentration to a density of 1.20g / cm 3 The paste is ready for use, and the solid obtained after solid-liquid separation is returned to the reconstituted tobacco leaf production process to produce reconstituted tobacco leaf base and coating liquid for use.

[0032] (3) Schisandra chinensis powder with a particle size of 100-300 mesh in step (1) is uniformly mixed with the coating liquid in the production of reconstituted tobacco l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com