A substrate capable of raising heating temperature and increasing smoke emission amount and a preparation method thereof

A technology of heating temperature and smoke generation, applied in the direction of tobacco, smoker's products, applications, etc., can solve the problems of uneven heating, scorch, not being fully heated, etc., achieve overall uniform heating, reduce consumption, reduce The effect of scorching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A base sheet for tobacco, mainly made of tobacco raw materials, plant fibers, pure silver wire and adhesive, wherein the proportion of pure silver wire added is 1% - 45% by weight.

[0050]The tobacco raw material is tobacco dust, tobacco leaf fragments, tobacco stems, low-grade tobacco leaves or a combination thereof. Pulverized tobacco raw materials are tobacco particles or powder formed by crushing tobacco raw materials, the diameter of the particles is 0.1mm-1mm, and the diameter of the powder is 0.01mm-0.1mm;

[0051] The plant fiber is a filamentous substance obtained by filtering the slurry obtained by soaking the plant in a chemical solvent or in water, and its length is 0.1mm-10mm, preferably 1mm-5mm. It is recommended to use wood pulp fibers commonly used in the industry as plant fibers, such as softwood pulp and hardwood pulp.

[0052] Adhesives are routinely used in the industry and can be directly purchased commercially, so no further description is given ...

Embodiment 2

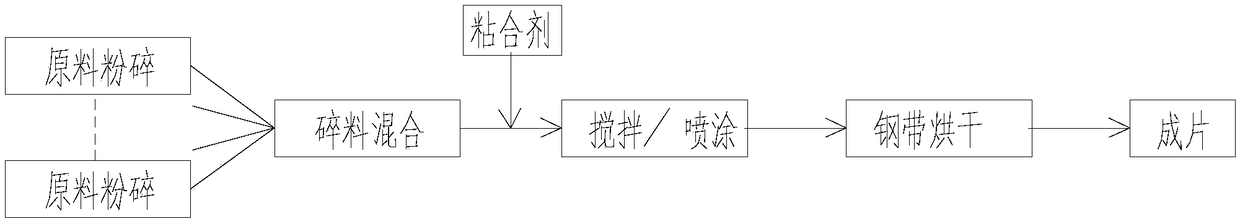

[0055] A method for preparing a tobacco base sheet, such as Figure 4 As shown, follow the steps below:

[0056] S1, pulverizing tobacco powder, tobacco leaf fragments, and tobacco stems to obtain a mixture 1;

[0057] S2, add pure silver wire to mixture 1 and continue mixing to obtain mixture 2;

[0058] S3, add adhesive to mixture 2 and continue to mix and stir to obtain mixture 3;

[0059] S4, the mixture 3 is coated on the steel belt and heated and dried to obtain a tobacco base sheet.

Embodiment 3

[0061] A method for preparing a tobacco base sheet, such as Figure 5 As shown, follow the steps below:

[0062] S1, tobacco powder, tobacco leaf fragments, and tobacco stems are leached, and solid and liquid are separated;

[0063] S2, the separated liquid is further evaporated and concentrated to prepare a coating liquid;

[0064] S3, the separated tobacco solid residue is decomposed and pulped, metal products are added to the slurry, mixed and dried to obtain a tobacco base sheet;

[0065] S4, uniformly coating the coating solution obtained in S2 on the tobacco substrate, and drying to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com