A fire-resistant and flame-retardant rail transit communication cable

A technology for rail transit and communication cables, applied in the direction of communication cables, insulated cables, cables, etc., can solve the problems of large attenuation changes of optical fibers, loss of the function of transmitting information, and the inability of the flame-retardant sheath to effectively block heat transfer. Effects of reducing heat, maintaining luminosity, and promoting rearrangement of ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

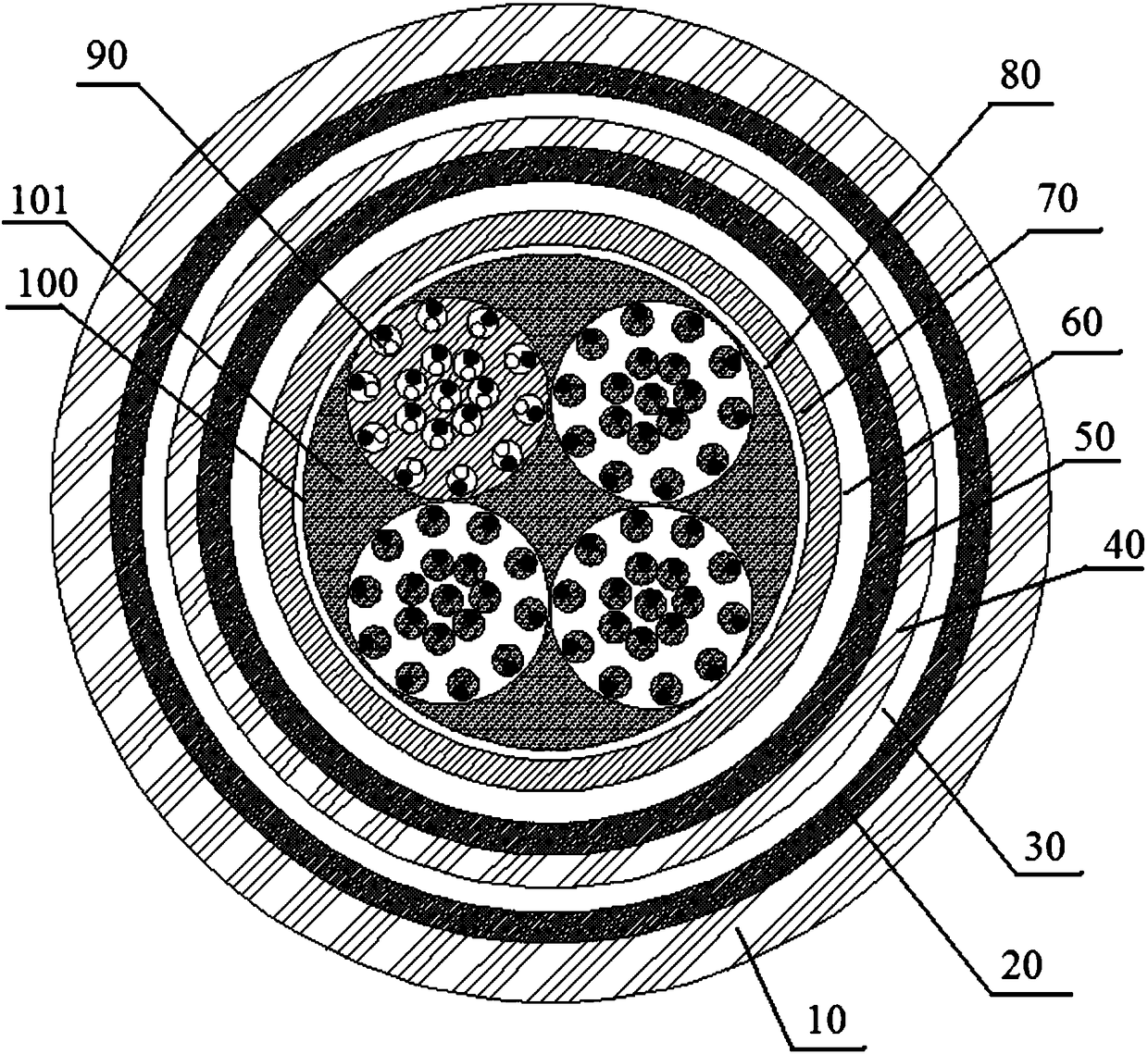

[0030] refer to figure 1 As shown, the structure of the communication cable in Example 1 includes from the outside to the inside: a low-smoke, halogen-free outer sheath 10, a first refractory layer 20, a high magnetic permeability steel tape armor layer 30, a low-smoke, halogen-free inner sheath Sheath 40, second refractory layer 50, aluminum sheath 60, PE heat insulation layer 70, water blocking layer 80, several strands of stranded insulating core wires 90, the above stranded insulating core wires 90 are covered by wrapping polyester tape 100 The grease 101 is filled between the stranded insulating core wire 90 and the wrapping polyester tape 100 , and the stranded insulating core wire 90 is covered with an insulating layer.

[0031] The communication cable of this embodiment has a double-layer fire-resistant layer in structure, and the structure is from the outside to the inside, and the layers are flame-retardant. The outer sheath can absorb most of the heat. The first fir...

Embodiment 2

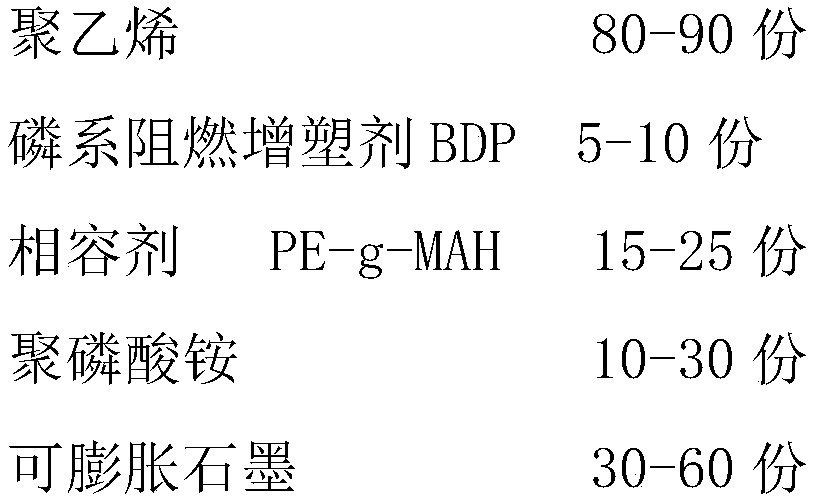

[0042] The structure of the communication cable in Embodiment 2 is the same as in Embodiment 1, wherein the above-mentioned low-smoke, halogen-free outer sheath 10 and low-smoke, halogen-free inner sheath 40 are both low-smoke, halogen-free polyethylene materials, calculated in parts by weight , the formulation of the above-mentioned low-smoke halogen-free polyethylene material is shown in Table 3.

[0043] Low-smoke halogen-free polyethylene material formula table in the embodiment 2 of table 3

[0044] components

Content (parts by weight)

polyethylene

85

Phosphorous Flame Retardant Plasticizer BDP

7

Compatibilizer PE-g-MAH

20

20

expandable graphite

40

[0045]Among them, in the above formula, the weight ratio of ammonium polyphosphate to expandable graphite is 1:3, ammonium polyphosphate and expandable graphite are synergistically flame-retardant in low-smoke halogen-free polyethylene ...

Embodiment 3

[0053] The structure of the communication cable in Embodiment 3 is the same as that in Embodiment 1, wherein the above-mentioned low-smoke, halogen-free outer sheath 10 and low-smoke, halogen-free inner sheath 40 are both low-smoke, halogen-free polyethylene materials, calculated in parts by weight , the formulation of the above-mentioned low-smoke halogen-free polyethylene material is shown in Table 5.

[0054] The low-smoke halogen-free polyethylene material formula table in the embodiment 3 of table 5

[0055] components

Content (parts by weight)

polyethylene

90

Phosphorous Flame Retardant Plasticizer BDP

10

Compatibilizer PE-g-MAH

25

Ammonium polyphosphate

30

expandable graphite

60

[0056] Among them, in the above formula, the weight ratio of ammonium polyphosphate to expandable graphite is 1:3, ammonium polyphosphate and expandable graphite are synergistically flame-retardant in low-smoke halogen-free po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com