Preparation method of cooling and aroma-enhancing particles for HNB cigarettes and cooling and aroma-enhancing particles for HNB cigarettes

A particle and cigarette technology, applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of low porosity on the surface of particles, affecting the quality of tobacco, and less smoke passing through, so as to reduce the broken rate, enhance the quality of tobacco, and reduce the use of effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Unless otherwise specified, the raw materials, solvents and auxiliaries in the examples of the present application were purchased through commercial channels and were not processed.

[0053] Instruments used in the test: electronic analytical balance, measuring cylinder, flue gas temperature detection device

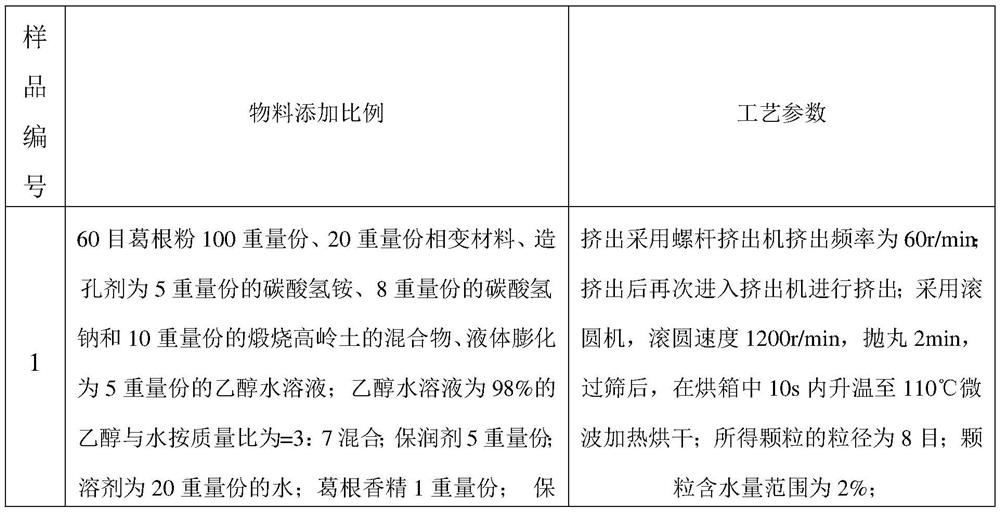

[0054] Examples 1-6 prepare flavor-enhancing and cooling granules 1-6

[0055] Prepare as follows:

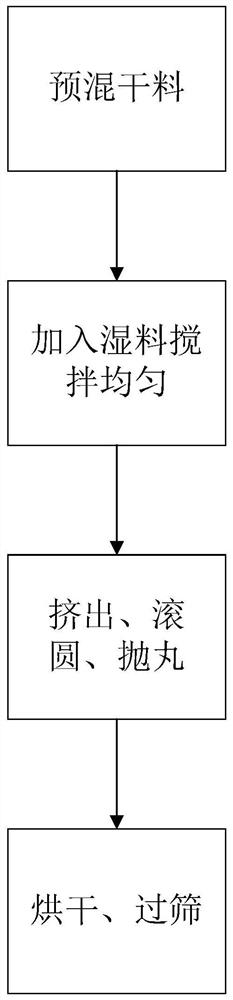

[0056] 1) After premixing 60-400 mesh plant fiber powder, phase change material (PEG) and pore-forming agent evenly, add humectant, solvent, essence, and liquid bulking agent and mix evenly to obtain a mixture;

[0057] 2) Extrude the obtained mixture at least twice, then carry out spheronization, shot blasting, drying, and sieving to obtain 8-20 mesh particles. The particle size is determined according to the mesh size of the sieve used; 30%;

[0058] The heating program in the drying step is to raise the temperature to above 110° C. within 10 seconds to 1 minu...

Embodiment 7

[0071] Example 7 Performance Detection of Cooling and Flavoring Granule Samples 1-6 and Comparative Samples 1-3

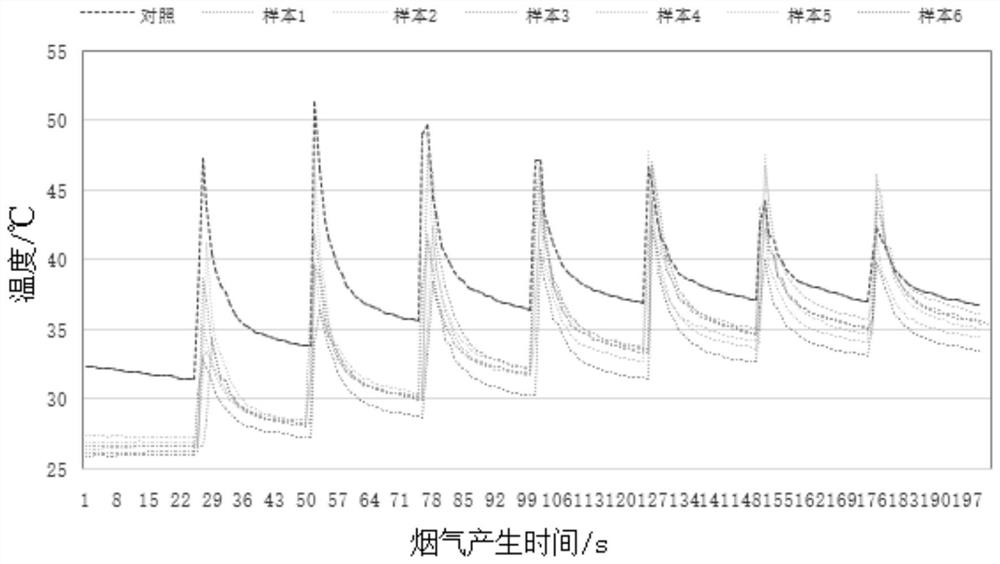

[0072] Cut out 5 mm from the cooling section of the new heat-not-burn (HNB) tobacco, take 100 mg of the samples 1-6 particles obtained in Examples 1-6 and replace them into the cooling section of the new-type tobacco, smoke for rating and measure the temperature of the flue gas. The control sample was a new type of heat-not-burn (HNB) tobacco that did not change the cooling section.

[0073] The porosity control sample is the kudzu root starch granules without expansion agent.

[0074] Cigarettes added with tangerine peel granules have an aroma of tangerine peel during smoking, indicating that the granules have a flavor-enhancing effect on cigarettes. The detected smoke temperature is 3-5°C lower than the peak temperature of smoke without granules, indicating that the granules have a cooling effect.

[0075] For the relationship between the flue gas temperature an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com