A kind of processing method of heating cigarette powder

A processing method and a technology for tobacco powder, which are applied in the directions of processing tobacco, tobacco, and preparing tobacco, can solve the problems of weak tobacco aroma and poor smoking taste, and achieve the advantages of improving the aroma of smoking, improving the thermal conductivity, and increasing the amount of smoke produced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

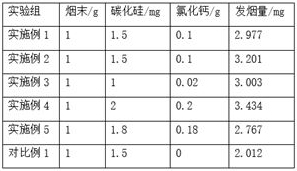

Examples

Embodiment 1

[0030] A method for processing heated cigarette powder, comprising the following steps:

[0031] Prepare 1g of tobacco powder, 1.5mg of silicon carbide, 1.5mg of low-ester pectin, 0.1g of calcium chloride, and add water to the calcium chloride to prepare a 3% calcium chloride solution.

[0032] (1) Add tobacco powder into 35mL ethanol solution, heat and reflux for 60min to obtain filter residue and ethanol extract.

[0033] Then the obtained filter residue was added to a citric acid solution with a concentration of 0.2 mol / L, heated to 40° C. for 60 minutes, and then filtered, and the obtained secondary filter residue was washed with distilled water until the pH was greater than 5.

[0034] (2) Mix the obtained secondary filter residue with silicon carbide and pectin into 15ml of water, stir evenly to obtain system a; add calcium chloride solution dropwise to system a while stirring rapidly, and continue stirring for 60 minutes after the dropwise addition is completed , and t...

Embodiment 2

[0037] A method for processing heated cigarette powder, comprising the following steps:

[0038] Prepare 1g of tobacco powder, 1.5mg of silicon carbide, 1.5mg of low-ester pectin, 0.1g of calcium chloride, and add water to the calcium chloride to prepare a 3% calcium chloride solution.

[0039] (1) Add tobacco powder into 35mL ethanol solution, heat and reflux for 60min to obtain filter residue and ethanol extract.

[0040] Then the obtained filter residue was added to a citric acid solution with a concentration of 0.2 mol / L, heated to 40° C. for 60 minutes, and then filtered, and the obtained secondary filter residue was washed with distilled water until the pH was greater than 5.

[0041] (2) Mix the obtained secondary filter residue with silicon carbide and pectin into 15mL of water, stir evenly to obtain system a; add calcium chloride solution dropwise to system a while stirring rapidly, and continue stirring for 60 minutes after the dropwise addition is completed , and t...

Embodiment 3

[0044] A method for processing heated cigarette powder, comprising the following steps:

[0045] Prepare 1g of tobacco powder, 1mg of silicon carbide, 1mg of low-ester pectin, and 2mg of calcium chloride, and add water to the calcium chloride to prepare a 2% calcium chloride solution.

[0046] (1) Add tobacco powder into 20mL ethanol solution, heat and reflux for 40min to obtain filter residue and ethanol extract.

[0047] Then the obtained filter residue was added to a hydrochloric acid solution with a concentration of 0.01mol / L, heated to 35° C. for 50 minutes, and then filtered, and the obtained secondary filter residue was washed with distilled water until the pH was greater than 5.

[0048] (2) Mix the obtained secondary filter residue with silicon carbide and pectin into 10mL of water, stir evenly to obtain system a; add calcium chloride solution dropwise to system a while stirring rapidly, and continue stirring for 50min after the dropwise addition is completed , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com