A kind of preparation method and application of tobacco smoking core material smoking agent

A technology of smoking agent and wick, which is applied in the direction of tobacco, application and treatment of tobacco, etc., can solve the problems affecting the sensory comfort and quality stability of cigarette products, the limitation of use range and addition amount, and the easy absorption of moisture and mildew by the wick material. problem, to achieve the effect of easy process, stable product quality and improved moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

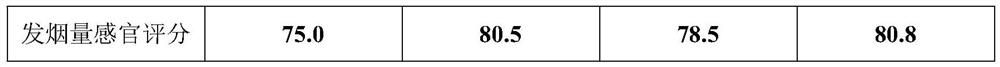

Embodiment 1

[0025] This embodiment is a novel tobacco smoking core material smoking agent, the preparation method of which comprises the following steps:

[0026] Step 1, take 4g of lotus root powder, 3g of beeswax and 2g of polyhydric alcohol and dissolve in distilled water, stir for 1h to obtain 4% lotus root starch sol; take 2g of sodium carboxymethyl cellulose and dissolve in distilled water, stir for 1h, and depressurize Deaeration, the obtained mass fraction is 2% sodium carboxymethyl cellulose hydrosol;

[0027] Step 2, mix the lotus root starch sol and the carboxymethyl cellulose sol described in step 1, stir for 1 hour, add 3g of tea polyphenols and 4g of glycerol, and form a film by casting method after defoaming, dry in the air, and make Get carboxymethyl cellulose-lotus root starch composite film, then add 10mL calcium chloride solution in the described carboxymethyl cellulose-lotus root starch composite film, cross-linking reaction, dry, make cross-linked carboxymethyl cellul...

Embodiment 2

[0037] This embodiment is a novel tobacco smoking core material smoking agent, the preparation method of which comprises the following steps:

[0038] Step 1, take 4g of lotus root powder, 3g of beeswax and 2g of polyhydric alcohol and dissolve in distilled water, stir for 1h to obtain 4% lotus root starch sol; take 2g of sodium carboxymethyl cellulose and dissolve in distilled water, stir for 1h, and depressurize Deaeration, the obtained mass fraction is 2% sodium carboxymethyl cellulose hydrosol;

[0039] Step 2, mix the lotus root starch sol and the carboxymethyl cellulose sol described in step 1, stir for 1 hour, add 3g of tea polyphenols and 4g of glycerol, and form a film by casting method after defoaming, dry in the air, and make Get carboxymethyl cellulose-lotus root starch composite film, then add 10mL calcium chloride solution in the described carboxymethyl cellulose-lotus root starch composite film, cross-linking reaction, dry, make cross-linked carboxymethyl cellul...

Embodiment 3

[0049] This embodiment is a novel tobacco smoking core material smoking agent, the preparation method of which comprises the following steps:

[0050] Step 1, take 4g of lotus root powder, 3g of beeswax and 2g of polyhydric alcohol and dissolve in distilled water, stir for 1h to obtain 4% lotus root starch sol; take 2g of sodium carboxymethyl cellulose and dissolve in distilled water, stir for 1h, and depressurize Deaeration, the obtained mass fraction is 2% sodium carboxymethyl cellulose hydrosol;

[0051] Step 2, mix the lotus root starch sol and the carboxymethyl cellulose sol described in step 1, stir for 1 hour, add 3g of tea polyphenols and 4g of glycerol, and form a film by casting method after defoaming, dry in the air, and make Get carboxymethyl cellulose-lotus root starch composite film, then add 10mL calcium chloride solution in the described carboxymethyl cellulose-lotus root starch composite film, cross-linking reaction, dry, make cross-linked carboxymethyl cellul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com