A preparation method of heat-not-burn tobacco products by optimized rolling method

A heat-not-burn and tobacco product technology, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, can solve problems such as uneven heat conduction of reconstituted tobacco leaves, unfavorable tobacco taste, and affecting the puffing sensory quality of reconstituted tobacco leaves, so as to improve smoking Effects of sensory quality, increased smoke release, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

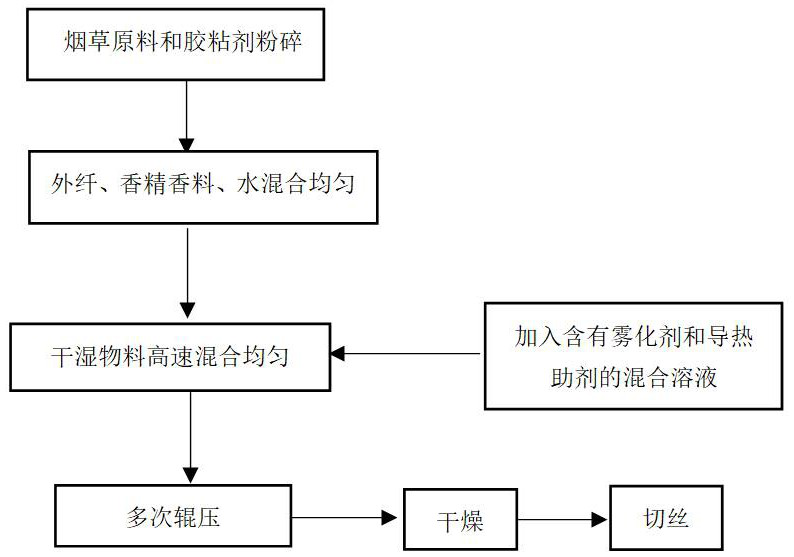

[0032] Embodiment 1 of the present invention provides a method for preparing heat-not-burn tobacco products by optimizing rolling method, the process is as follows figure 1 shown, including the following steps:

[0033] (1) Mixing tobacco raw materials and adhesives according to a certain ratio, and transport them to a pulverizer for crushing treatment until the particle size is 60-200 mesh. Among them, the adhesive is sodium alginate, and the amount of adhesive added is 3% of the tobacco raw materials ;

[0034] (2) Prepare flavors and fragrances, wood pulp fibers, and 60°C hot water in a certain proportion, stir at high speed to disperse evenly, and slowly add the above-mentioned (1) uniformly mixed tobacco raw materials and adhesives at the same time, and stir evenly. Add flavor and fragrance according to 1% of tobacco raw materials, add wood pulp fiber at 5%, and add water at 8%;

[0035] (3) Prepare a mixed solution of an atomizer and a heat conduction aid while heating...

Embodiment 2

[0038] Embodiment 2 of the present invention provides a method for preparing heat-not-burn tobacco products by an optimized rolling method, comprising the following steps:

[0039] (1) Tobacco raw materials and adhesives are mixed according to a certain ratio, and then transported to a pulverizer for crushing, and crushed to a particle size of 60-200 mesh, wherein the adhesive is CMC, and the amount of adhesive added is 5% of the tobacco raw materials;

[0040](2) Prepare flavors and fragrances, wood pulp fibers, and 60°C hot water in a certain proportion, stir at high speed to disperse evenly, and slowly add the above-mentioned (1) uniformly mixed tobacco raw materials and adhesives at the same time, and stir evenly. Add flavor and fragrance according to 3% of tobacco raw materials, add hemp pulp fiber at 3%, and add water at 10%;

[0041] (3) Prepare a mixed solution of atomizing agent and heat conduction aid under the condition of heating to 80°C and stirring; among them, t...

Embodiment 3

[0044] Embodiment 3 of the present invention provides a method for preparing heat-not-burn tobacco products by an optimized rolling method, comprising the following steps:

[0045] (1) The tobacco raw material and the adhesive are mixed according to a certain ratio, and then sent to the pulverizer for crushing treatment, and crushed to a particle size of 60-200 mesh, wherein the adhesive is chitosan, and the amount of the adhesive added is 5% of the tobacco raw material ;

[0046] (2) Prepare flavors and fragrances, wood pulp fibers, and 60°C hot water in a certain proportion, stir at high speed to disperse evenly, and slowly add the above-mentioned (1) uniformly mixed tobacco raw materials and adhesives at the same time, and stir evenly. Add flavor and fragrance according to 5% of tobacco raw materials, add wood pulp fiber at 12%, and add water at 20%;

[0047] (3) Prepare a mixed solution of atomizing agent and heat conduction aid under the condition of heating to 80°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com