Aerosol generating device with flow guide structure

An aerosol generation and aerosol technology, which is applied to tobacco and other directions, can solve the problems of high glycerin and moisture content, difficulty in fully releasing the original aroma components of tobacco, affecting the actual feeling of consumers, etc. Optimizing, adjusting and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

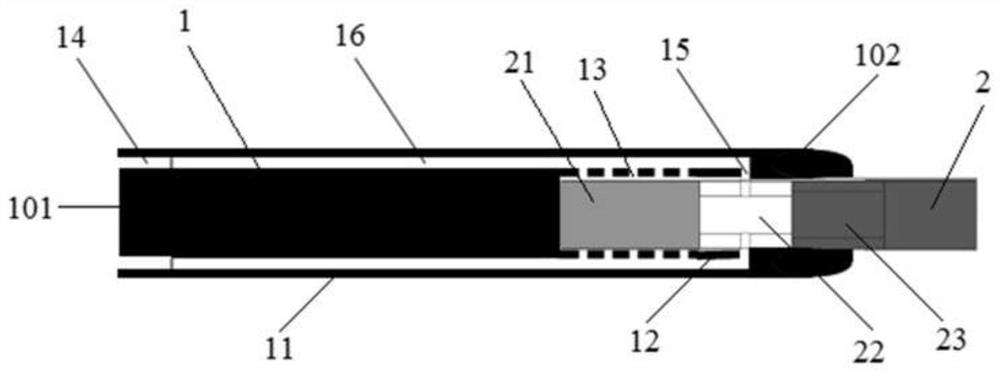

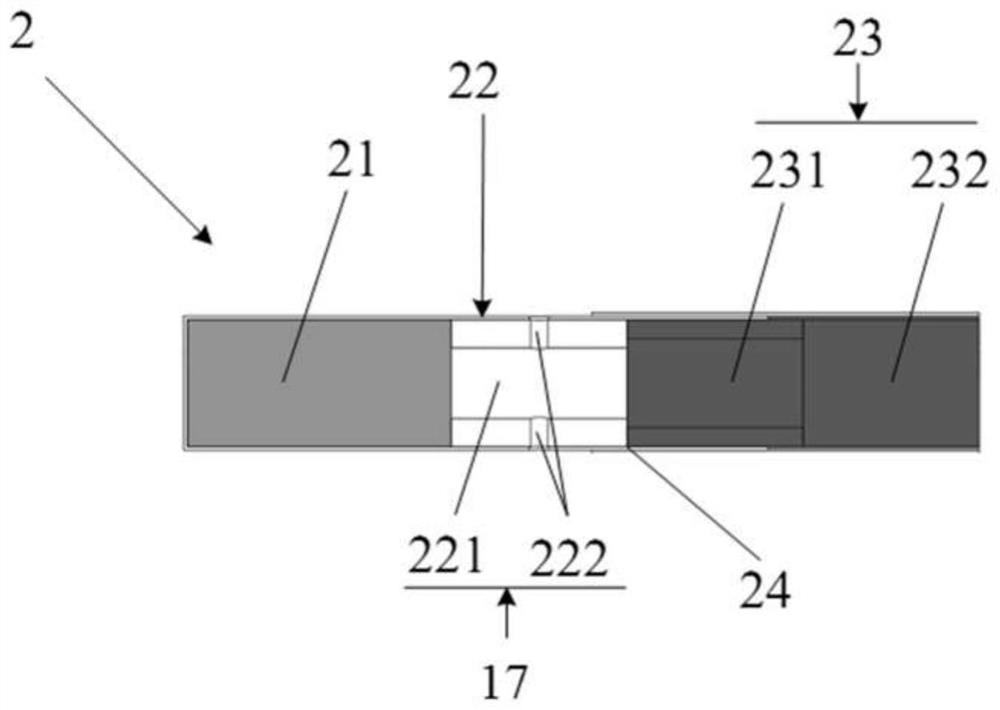

[0026] The illustrative and non-limiting embodiments of the present invention will be described in detail below with reference to the accompanying drawings, and the aerosol generating device according to the present invention will be further described.

[0027] An aerosol-generating device according to the invention comprises an aerosol-generating element and an aerosol-generating article disposed coaxially. The aerosol generating element has a distal end portion in an axial direction and a proximal end portion opposite to the distal end portion and having an opening, and includes a housing, an internal working element accommodated in the housing, and a receiving sleeve. An internal working element is disposed proximate the distal portion. For example, the internal working elements may include a power supply (eg a lithium-ion power supply or similar) and circuit boards and wires (not shown) for controlling the operation of the aerosol generating article, in particular for cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com