Smoke generating product and electronic cigarette

A technology of smoking products and electronic cigarettes, which is applied in the direction of smoker's products, tobacco, applications, etc., can solve the problems of low utilization rate of tobacco raw materials and small number of puffing ports, so as to promote utilization rate, improve smoking feeling, and improve product quality. The effect of smoke volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

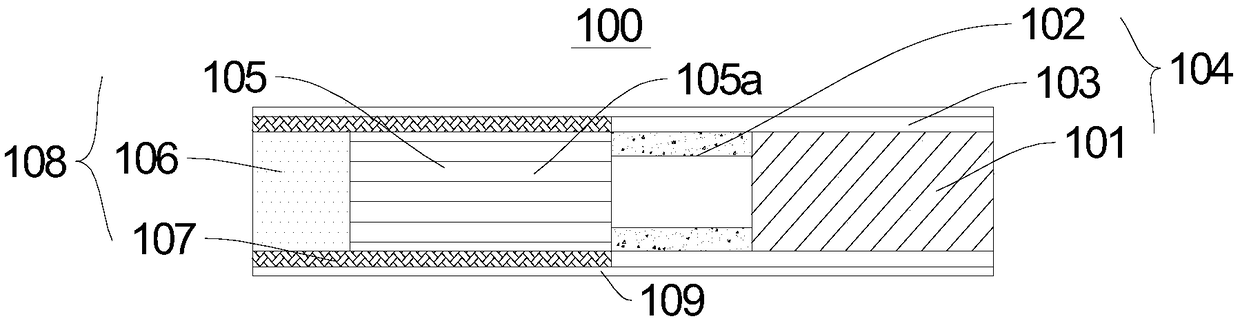

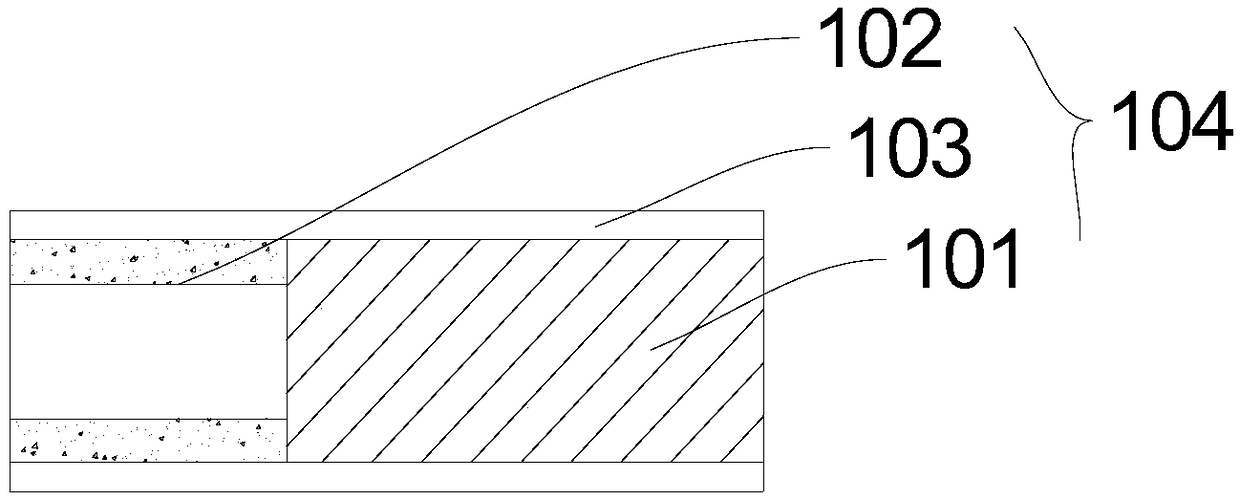

[0032] Such as figure 1 As shown, the smoking article 100 includes a smoking section 101, and the smoking section 101 is mainly used to generate a large amount of aerosol, thereby satisfying the user's puffing sensation. The smoking segment 101 may be a cylinder formed by cutting the aroma-producing material sheet into a strip structure or wrinkling it, and then wrapping it with paper or other wrappers. Or the smoking section 101 can also cut the aroma-producing material into strips with a width of 0.5mm to 1.8mm and a length of 2mm to 40mm, and fill them in a cylindrical cavity formed by forming paper or other wrappings in a random manner through a cigarette maker . The flavoring material may contain tobacco or other flavored volatile flavoring compounds. Preferably, the wrapper wrapping the aroma-producing material is made of oil-proof forming paper, so as to ensure the smoking effect of the smoking section 101 .

[0033] Further, the length of the smoking section 101 is ...

Embodiment 2

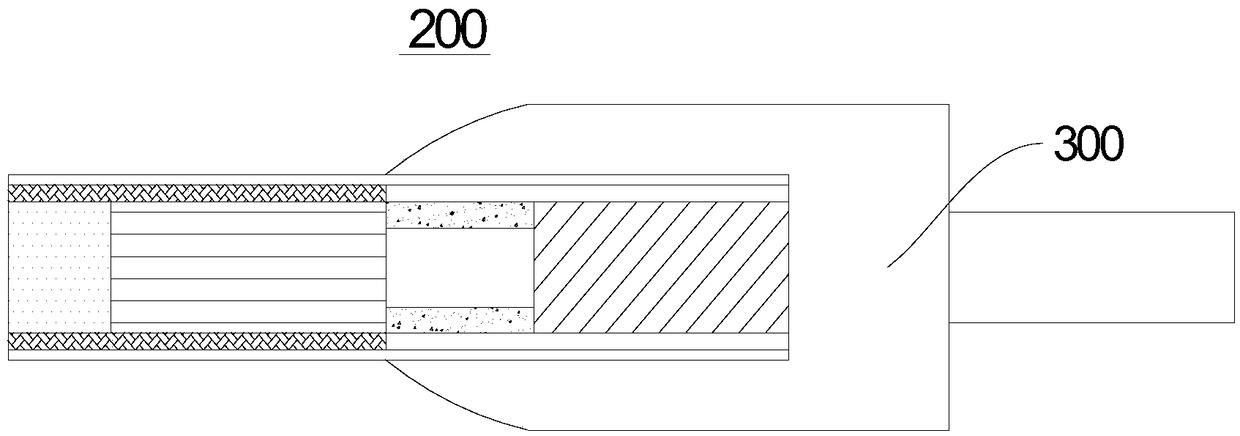

[0044] see image 3 This embodiment provides an electronic cigarette 200, which includes a heater 300 and the smoking article 100 of Embodiment 1, the smoking section 101, the isolation section 102, and the flavoring and cooling section 105 are respectively connected to the heater 300.

[0045] Specifically, combined with image 3 and Figure 4 , the heater 300 includes a heater body 310, the heater body 310 is a hollow structure, the heater body 310 can be a cylinder, a cube or other geometry, preferably a cylinder, since the smoking article 100 is a cylinder structure, the heater 300 The use of a cylinder is more conducive to heating the smoking article 100 by the heater 300 .

[0046] Further, the heater 300 includes a first heating assembly 320, the first heating assembly 320 is arranged in the heater body 310 and connected with the heater body 310, the isolation section 102 and the smoking section 101 are respectively connected with the first heating assembly 320 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com