A preparation equipment for powder injection molding feed

A powder injection molding and equipment technology, applied in the field of powder injection molding, can solve the problems of the influence of the feed preparation process, the inability to prepare the feed, and reduce production efficiency, so as to reduce the crushing process, reduce reheating, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

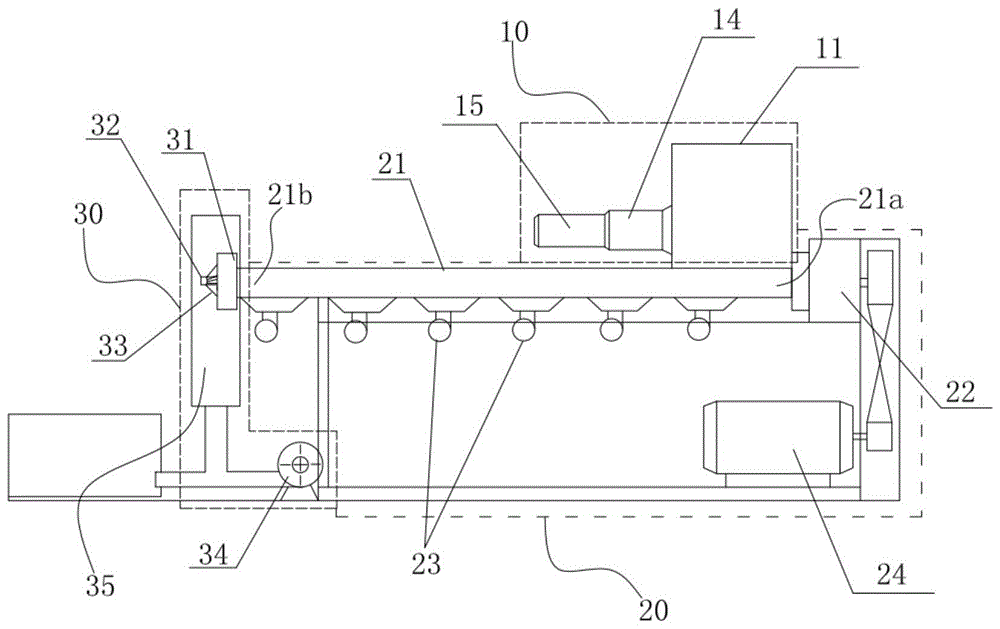

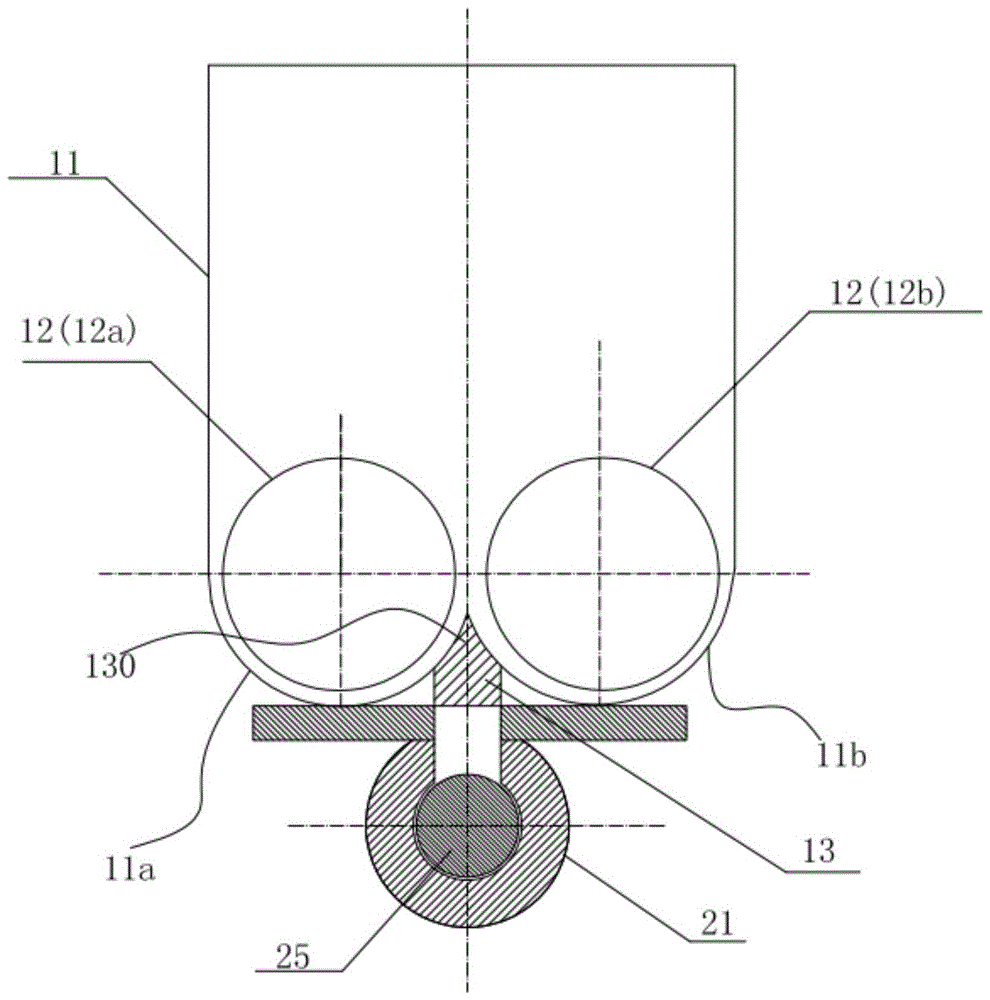

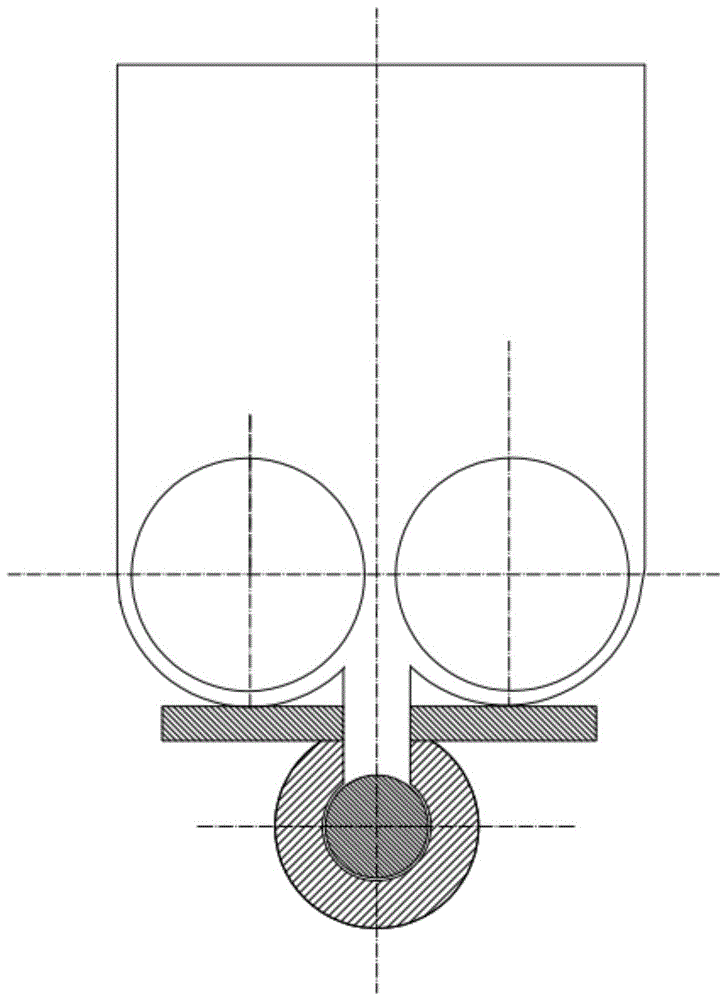

[0021] The present invention provides a figure 1 The equipment shown is used to prepare powder injection molding (PIM) feedstock, including metal powder injection molding (MIM) and ceramic powder injection molding (CIM) feedstock. like figure 1 As shown, the equipment includes a kneading device 10, an extruding device 20 and a pelletizing device 30, the discharge port of the kneading device 10 communicates with the inlet port 21a of the barrel 21 of the extruding device 20, and the pelletizing device 30 is connected to the extruding device 20. The outlet end 21b of the barrel 21 of the device 20, so that the powder material directly enters the extruding device 20 after being kneaded by the kneading device 10, and directly enters the pelletizing device 30 after passing through the extruding device 20 for hot-cut air-cooled gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com