Method for recycling active substances from waste pieces of positive poles of lithium ion batteries

A lithium-ion battery and active material technology, which is applied in the field of recovery and reuse of active materials on positive electrode waste, can solve the problems of increased viscosity of organic solvents, high economic costs, poor recycling performance, etc., to achieve increased viscosity and simple process , Save the effect of crushing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

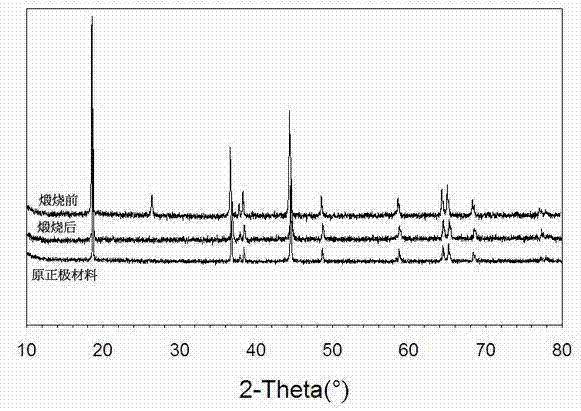

[0017] (1) For collected ternary materials (LiCo x Ni y mn z o 2 , x+y+z=1) Sorting the waste positive electrode of the secondary battery, cleaning the waste positive electrode with dirty surface with water, ethanol, acetone or N-methylpyrrolidone to clean the surface and proceed to step (2) , the clean positive electrode waste can directly enter step (2);

[0018] (2) Add 50g of clean positive electrode waste to the expansion agent of dimethyl sulfoxide and ethanol with a mass percentage of dimethyl sulfoxide of 50%, so that the drug film surface on the positive electrode waste is in effective contact with the expansion agent , the temperature of the solution was kept at 60°C for 0.2 h, stirring or ultrasonication would help the drug film surface to fall off the aluminum foil quickly;

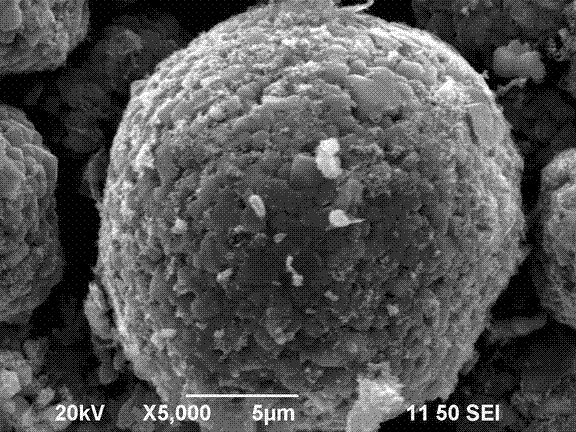

[0019] (3) Sieve or pick out the aluminum foil that is separated from the drug film surface, centrifuge, settle, sieve or filter the expansion agent containing the drug film surface to ach...

Embodiment 2

[0027] (1) For collected LiMn 2 o 4 Sorting the positive electrode waste of the secondary battery, cleaning the positive electrode waste with dirty surface with water, ethanol, acetone or N-methylpyrrolidone, making the surface clean and then proceeding to step (2), the clean positive electrode waste can be directly entered step (2);

[0028] (2) Put 50g of clean positive electrode waste into the expansion agent of dimethyl sulfoxide and water with a mass percentage of dimethyl sulfoxide of 90%, so that the drug film surface on the positive electrode waste is in effective contact with the expansion agent , the solution temperature is kept at 80°C for 0.1h;

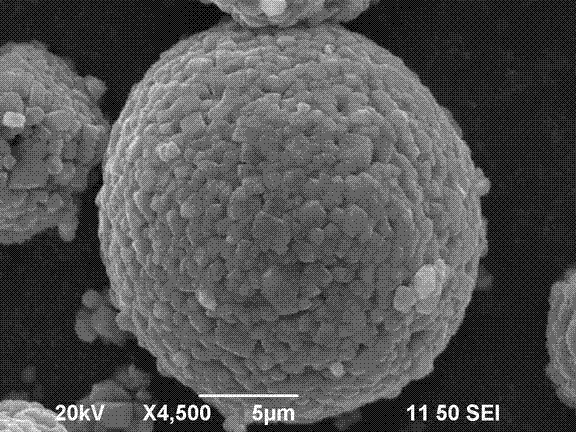

[0029] (3) Sieve or sort out the aluminum foil that is separated from the drug film surface, centrifuge or filter the expansion agent containing the drug film surface to achieve solid-liquid separation;

[0030] (4) Wash the centrifuged or filtered solid active substance with 100ml N-methylpyrrolidone for 1-4 times;

...

Embodiment 3

[0036] (1) For collected LiMn 2 o 4 Sorting the positive electrode waste of the secondary battery, cleaning the positive electrode waste with dirty surface with water, ethanol, acetone or N-methylpyrrolidone, making the surface clean and then proceeding to step (2), the clean positive electrode waste can be directly entered step (2);

[0037] (2) Put 50g of the clean positive electrode waste into the expansion agent of dimethyl sulfoxide and acetone with a mass percentage of dimethyl sulfoxide of 20%, so that the drug film surface on the positive electrode waste is in effective contact with the expansion agent , the solution temperature was kept at 19°C for 36h;

[0038] (3) Sieve or sort out the aluminum foil that is separated from the drug film surface, centrifuge or filter the expansion agent containing the drug film surface to achieve solid-liquid separation;

[0039] (4) Wash the centrifuged or filtered solid active substance with 100ml acetone for 1-4 times;

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com