Activated coke for absorbing dioxin in flue gas and preparation method thereof

A technology of activated coke and flue gas, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of low cost and high macropore content, and achieve low cost, high yield, and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

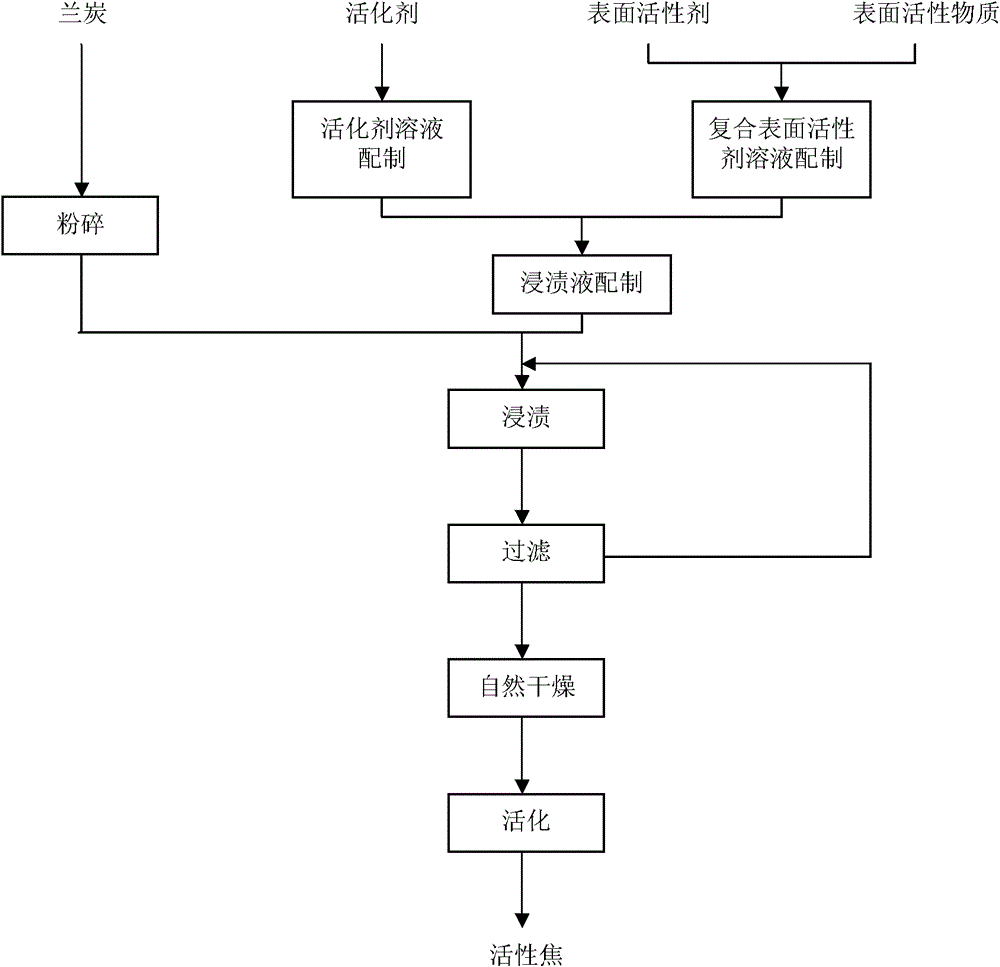

Image

Examples

Embodiment 1

[0029] The coal semi-coke is pulverized and sieved into 80-mesh powder for later use. A complex surfactant solution was prepared by dissolving 0.25g sodium fatty alcohol polyoxyethylene ether sulfonate and 1.25g isopropanol in 48.5mL water. Dissolve 347.8g of NaOH (200g of Na ions) in an appropriate amount of water and mix with the above composite surfactant solution, stir and add water to adjust the volume of the solution to 5L.

[0030] Then, weigh 1Kg of pulverized semi-coke, immerse in 5L of activator impregnation solution, filter and separate after 4h. The impregnated semi-coke was naturally dried at room temperature to a moisture content of 20%, and then placed in a carbonization furnace with N 2 Activation treatment at 900°C for 3.5h under protection, and in N 2 Protected cooling treatment until the temperature is lowered to below 100°C to prepare activated coke for the adsorption of dioxins in flue gas. The adsorption value of activated pyromethylene blue is determi...

Embodiment 2

[0032] The coal semi-coke is pulverized and sieved into 80-mesh powder for later use. Dissolve 0.25g of sodium fatty alcohol polyoxyethylene ether sulfonate and 1.25g of isopropanol in 48.5mL of water to prepare a composite surfactant solution. 460.9g Na 2 CO 3 (200g of Na ions) was dissolved in an appropriate amount of water and added to the above composite surfactant solution, stirred and added water to adjust the volume of the solution to 5L.

[0033] Then, weigh 1Kg of pulverized semi-coke, immerse in 5L of activator impregnation solution, filter and separate after 4h. The impregnated semi-coke was naturally dried at room temperature to a moisture content of 20%, and then placed in a carbonization furnace with N 2 Activation treatment at 900°C for 3.5h under protection, and in N 2 Protected cooling treatment until the temperature is lowered to below 100°C to prepare activated coke for the adsorption of dioxins in flue gas.

Embodiment 3

[0035] The coal semi-coke is pulverized and sieved into 80-mesh powder for later use. Dissolve 0.5g sodium lignosulfonate and 1.0g ethanol in 98.5mL water to prepare composite surfactant solution. Dissolve 347.8g NaOH (Na ion 200g) with an appropriate amount of water and add the complex surfactant solution, stir and add water to adjust the volume of the solution to 5L.

[0036] Then, weigh 1Kg of pulverized semi-coke, immerse in 5L of activator impregnation solution, filter and separate after 4h. The impregnated semi-coke was naturally dried at room temperature to a moisture content of 20%, and then placed in a carbonization furnace with N 2 Activation treatment at 900°C for 3.5h under protection, and in N 2 Protected cooling treatment until the temperature is lowered to below 100°C to prepare activated coke for the adsorption of dioxins in flue gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com