Method for preparing silumin and Al-Si-Mn-Fe-Ti alloy by using high-aluminum fly ash

A technology of high-alumina fly ash and silicon-aluminum alloy, which is applied in the field of high-alumina fly ash to prepare silicon-aluminum alloy and aluminum-silicon-manganese-ferro-titanium alloy, can solve the problems of restricting the development of the aluminum industry, high production cost, and long production cycle. Achieve the effects of reducing the crushing process, shortening the sintering time, and improving the strength of the ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

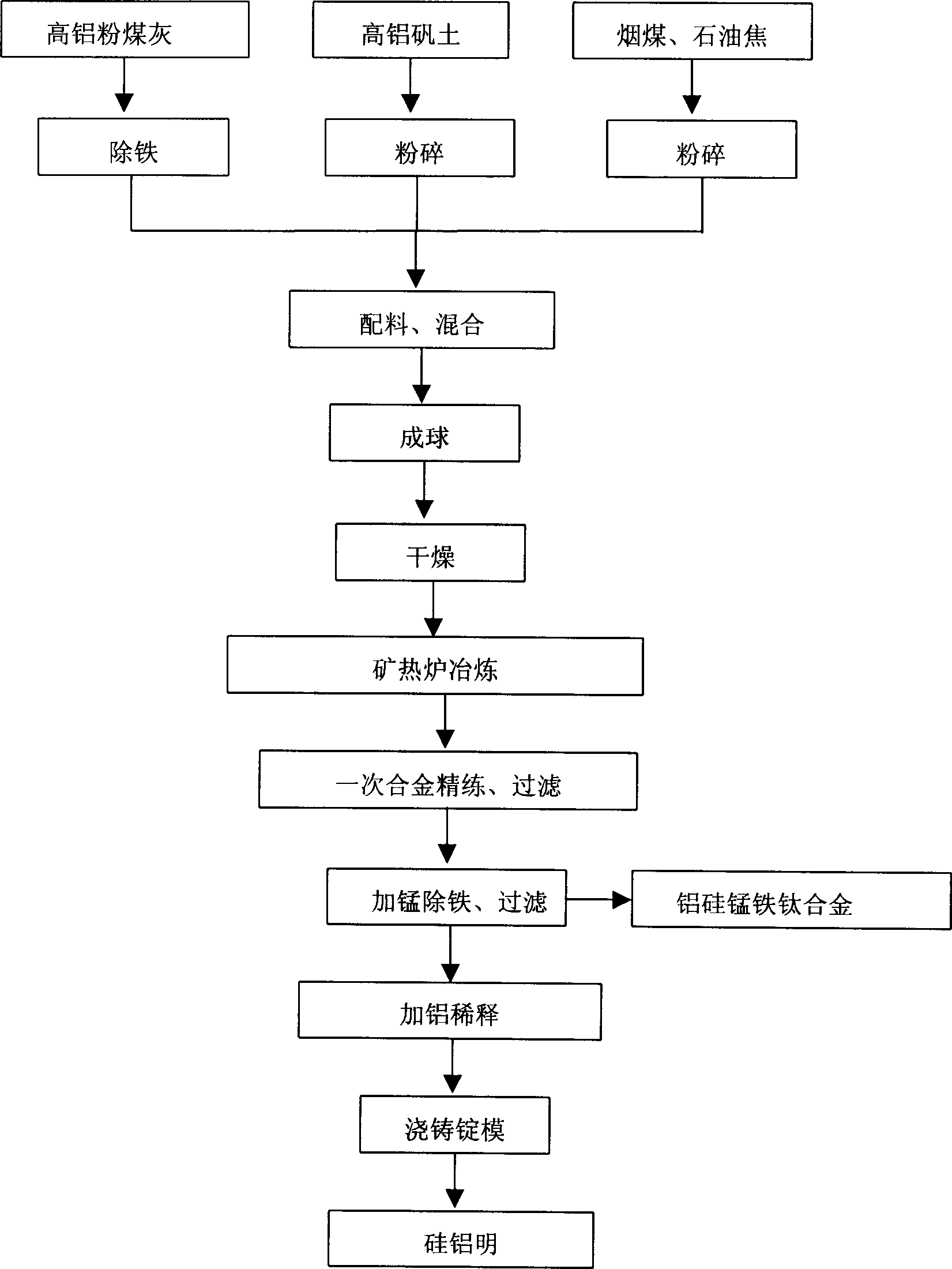

[0029] Referring to accompanying drawing, utilize high-aluminum fly ash to prepare the method for silicon-aluminum alloy and aluminum-silicon-manganese-iron-titanium alloy among the present invention:

[0030] ① Select Al-containing 2 o 3 52%, SiO 2 38% and Fe 2 o 3 2.5% high aluminum fly ash as the main raw material, and adding Al 2 o 3 75%, Fe 2 o 3 0.5% high bauxite and reducing agent bituminous coal and petroleum coke with low ash content, high fixed carbon content and good caking property. After removing iron from high alumina fly ash, Fe 2 o 3 The content is less than 1.5%, and the high alumina bauxite, bituminous coal and petroleum coke are crushed at the same time.

[0031] ②The treated high-alumina fly ash, high-alumina bauxite, bituminous coal and petroleum coke according to the proportion of Al 2 o 3 / SiO 2 Dosing and mixing as in 1.8.

[0032] ③ Add 5% binder papermaking black liquor and water to the mixture, mix well and put it into a ball forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com