Device for treating biurea condensation sewage generated from preparation of ADC (Azodicarbonamide) foaming agent with urea method and use method of device

A technology of ADC foaming agent and sewage treatment device, which is applied in the field of preparation of ADC foaming agent and biuret condensation sewage treatment device by urea method, can solve the problems of low resource reuse rate, large amount of oxidant use, and difficulty in reaching COD standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

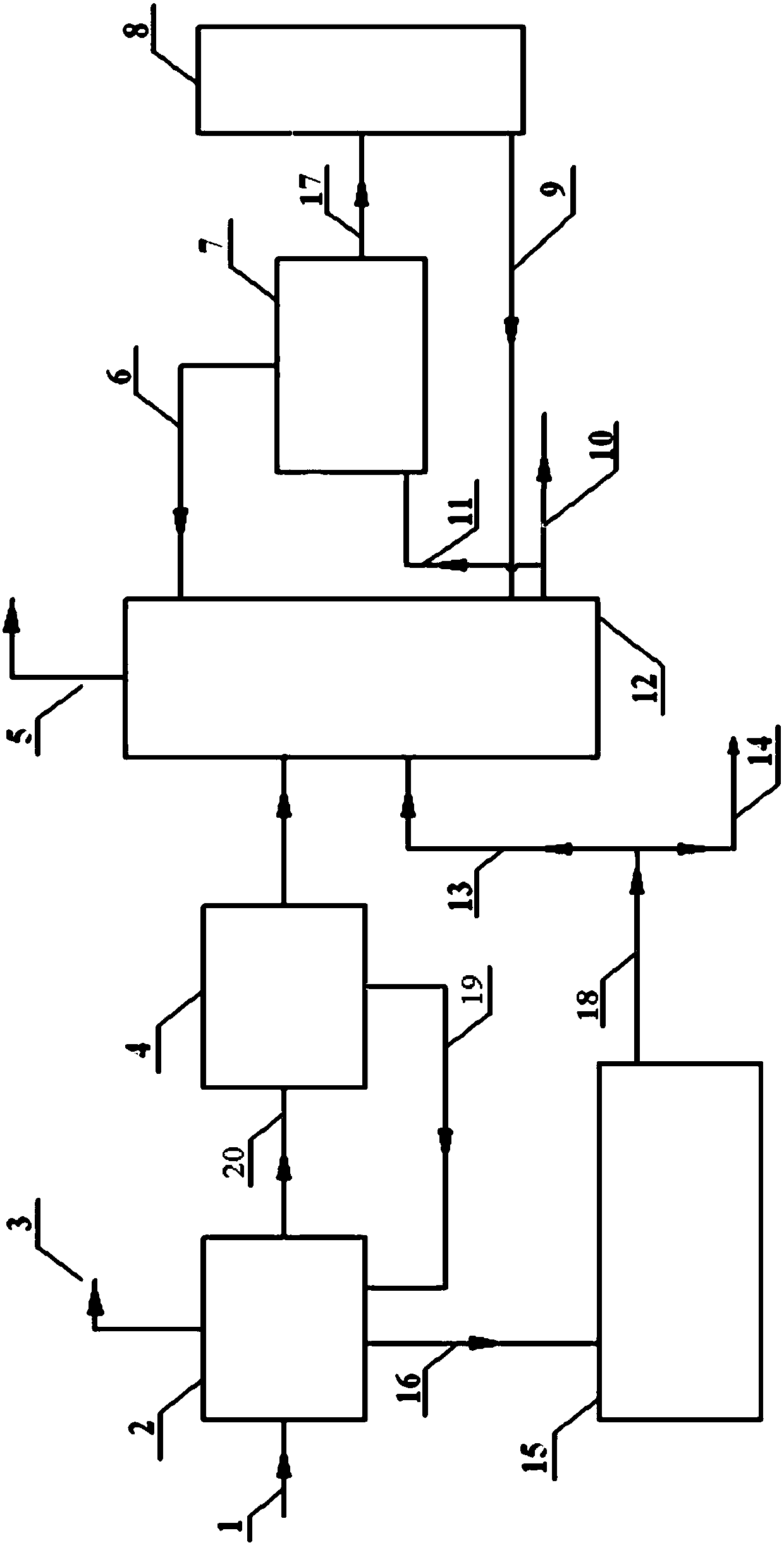

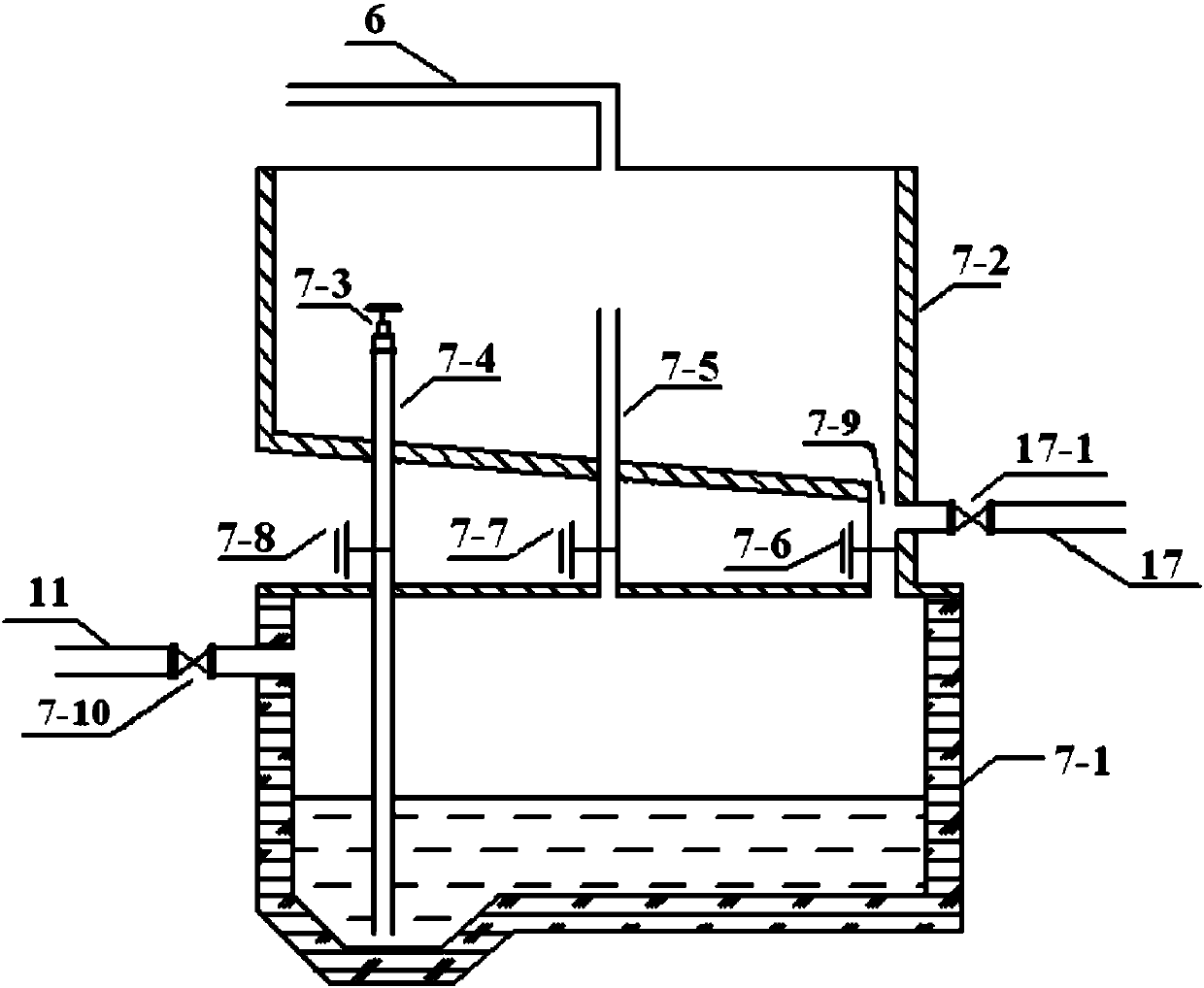

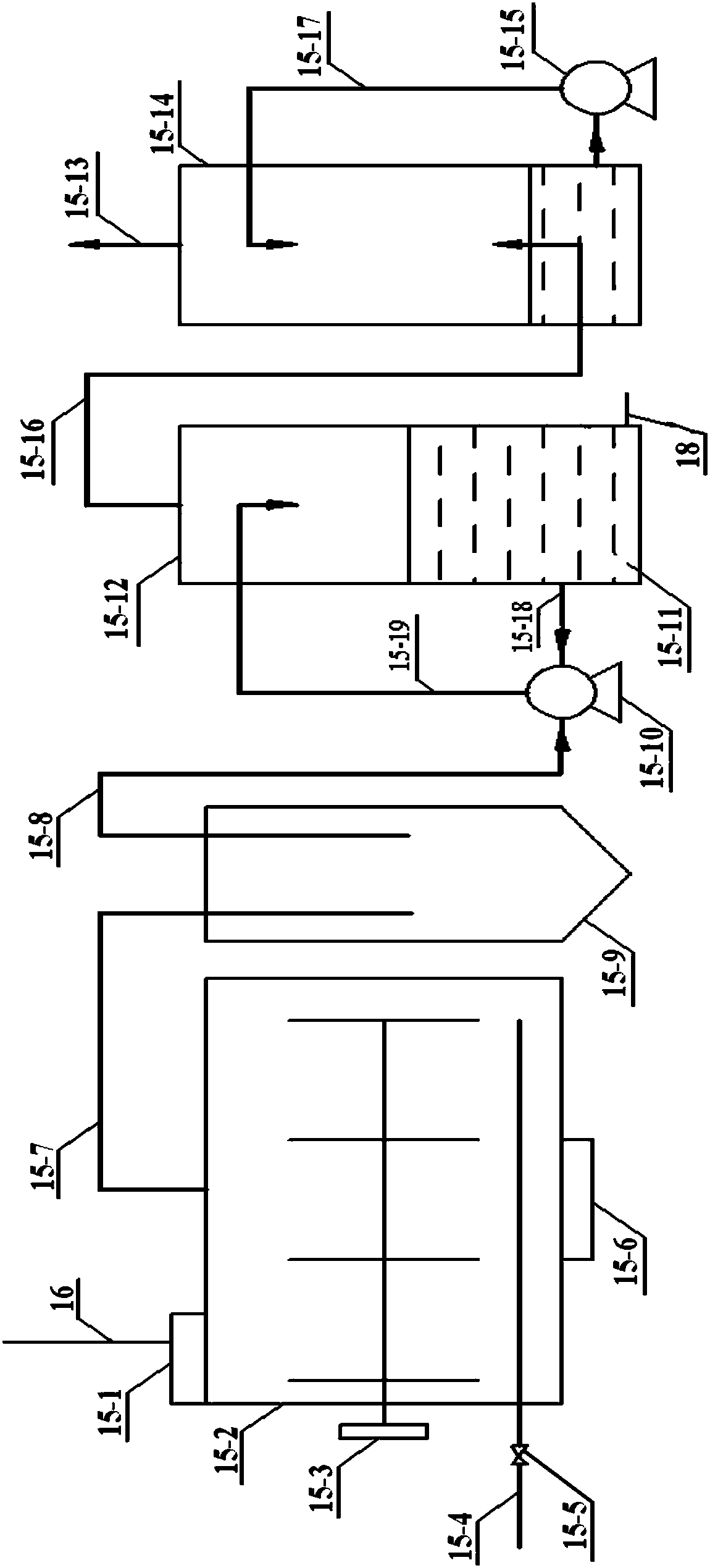

[0026] Specific implementation mode one: see figure 1 , 2 And 3, the present embodiment is a kind of urea method to prepare ADC foaming agent biurea condensation sewage treatment device, specifically by evaporation crystallizer 2, condensate drainage pipeline 3, solid salt output pipeline 16, concentrated liquid output pipe Road 20, high-temperature salt bath decomposition and gas absorption system 15, main absorption liquid drainage pipe 18, first branch drainage pipe 13 of absorption liquid, second branch drainage pipe 14 of absorption liquid, ammonia rectification tower 12, ammonia water drainage pipe 5, First ammonia rectification tower bottom liquid drain pipe 11, second ammonia rectification tower bottom liquid drain pipe 10, pressurized hydrolysis-flash system 7, flash tank exhaust pipe 6, flash tank drain pipe 17 , an oxidation tank 8, an oxidation tank drain pipe 9, a cooling crystallization system 4 and a return line 19;

[0027] The evaporation crystallizer 2 is p...

specific Embodiment approach 2

[0030] Specific implementation mode two: see figure 1 , 2 And 3, the present embodiment is the urea method of specific embodiment one to prepare the using method of ADC blowing agent biurea condensation sewage treatment device, specifically as follows:

[0031] The diuret condensation sewage, which has been filtered to remove suspended solids by precipitation, enters the evaporation crystallizer 2 through the water inlet pipe 1 of the evaporation crystallizer 2. liquid reuse, a part of the condensed liquid is discharged up to standard after being treated, and the concentrated liquid obtained by evaporation, concentration and crystallization of sewage enters the cooling crystallization system 4 through the concentrated liquid output pipeline 20; when the chlorine in the concentrated liquid obtained by evaporation, concentration and crystallization of sewage When the concentration of ammonium chloride was less than the saturation solubility of ammonium chloride, return to the e...

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 2 is that sodium hydroxide is added to the concentrated solution discharged from the cooling crystallization system 4 to adjust the pH to 10. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com