Cooling liquid recovery device of numerical control machine tool

A recovery device and technology of CNC machine tools, which are applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of easy blockage of drainage pipes, waste of resources, and the inability to use coolant directly, etc., to achieve the filtering effect Good, the effect of improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

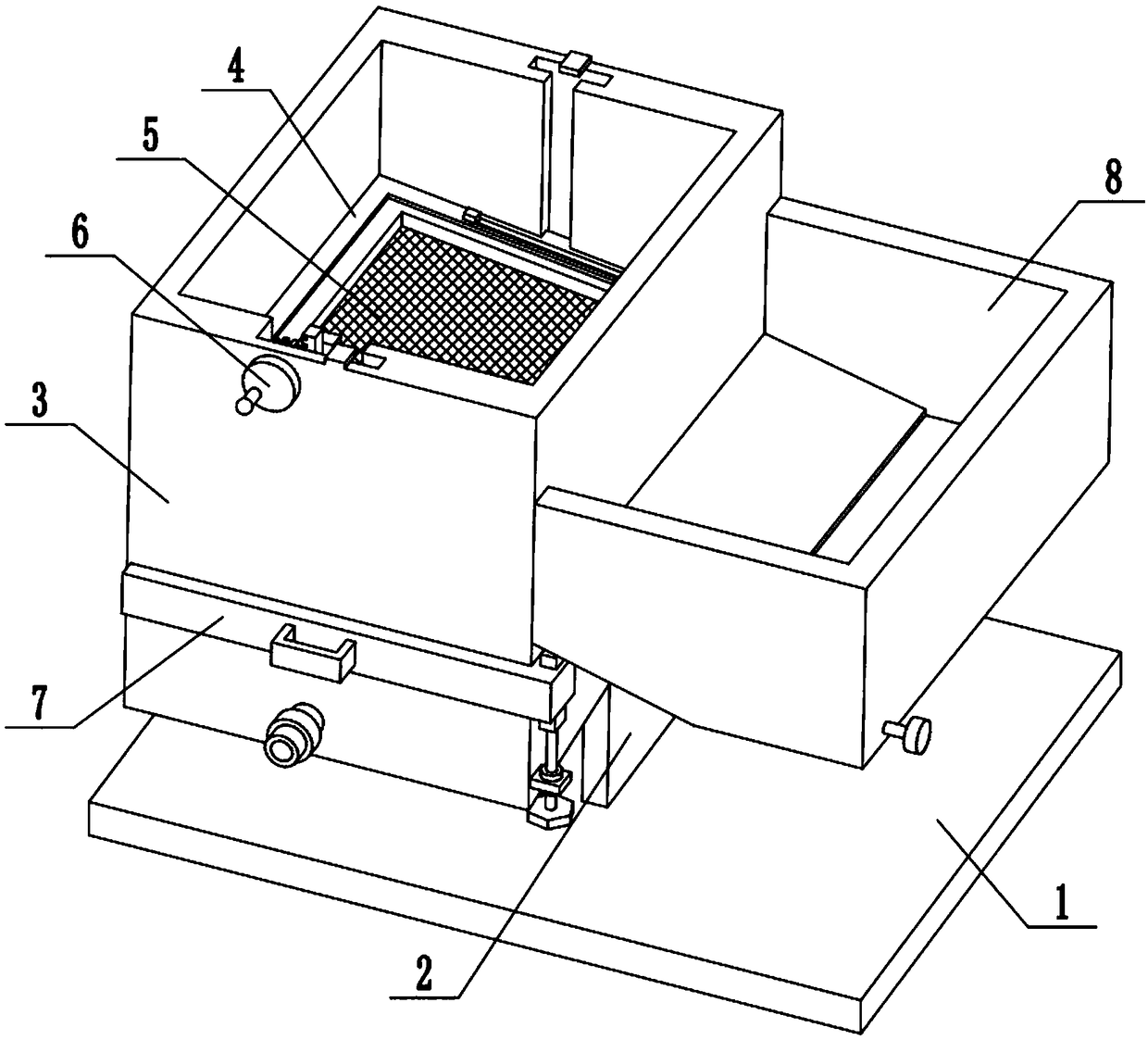

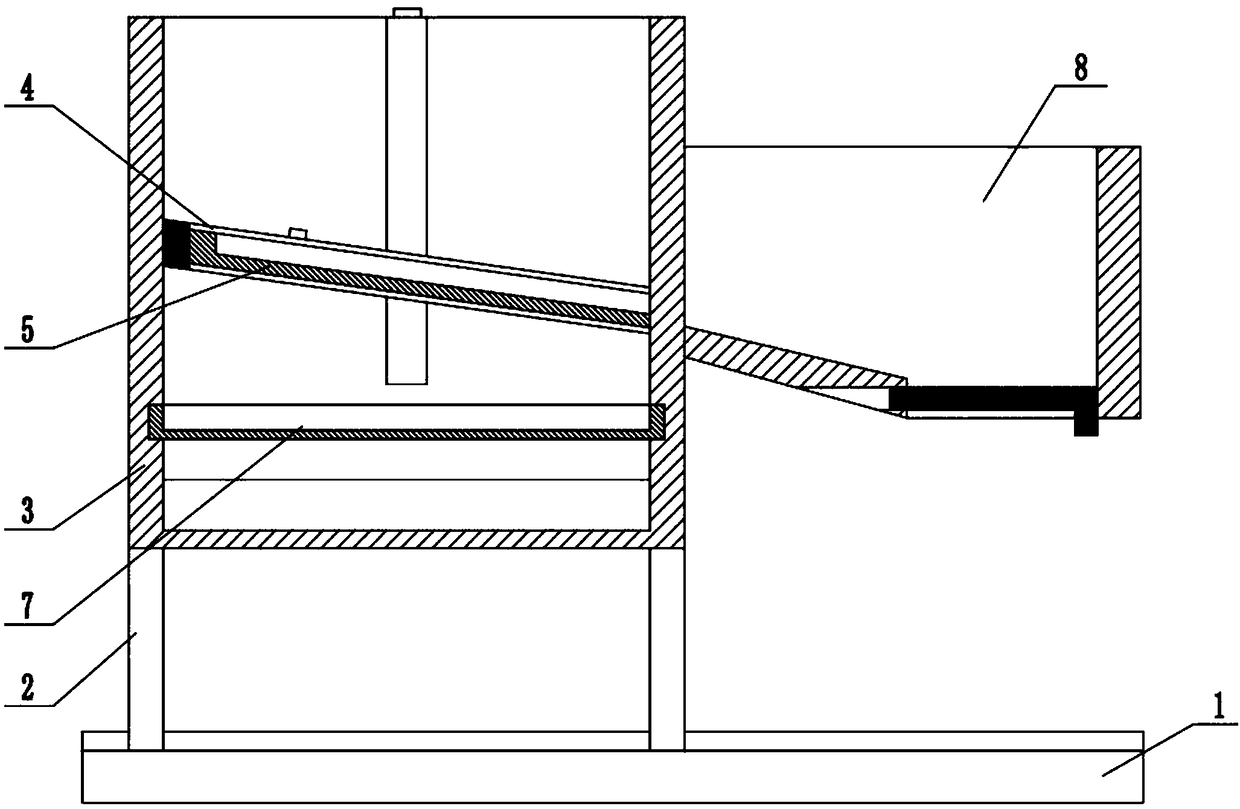

[0034] Combine below Figure 1-15Description of this embodiment, a coolant recovery device for CNC machine tools, including a base 1, a support base 2, a coolant filter box 3, a filter plate slide 4, a primary filter assembly 5, a control assembly 6, a secondary filter assembly 7 and Iron chips cooling box 8, the coolant filter box 3 is fixedly connected to the base 1 through two support bases 2, the filter plate sliding seat 4 is slidably connected to the upper end of the coolant filter box 3, and the primary filter assembly 5 is slidably connected In the filter plate slide 4, the control component 6 is rotatably connected to the upper end of the coolant filter box 3, the control component 6 is meshed with the filter plate slide 4 for transmission connection, and the secondary filter component 7 is slidably connected in the center of the coolant filter box 3. At the end, the chip cooling box 8 is fixedly connected to the coolant filter box 3. When the present invention is in...

specific Embodiment approach 2

[0035] Combine below Figure 1-15 To illustrate this embodiment, the coolant filter box 3 includes a filter box body 3-1, a drain pipe 3-2 with a control valve, a front T-shaped chute 3-3, and a rear T-shaped chute 3-4 , block 3-5, gear groove 3-6, circular through hole 3-7 and filter plate chute 3-8; the filter box body 3-1 is fixedly connected on the base 1 through two support seats 2, and the filter box The lower end of the body 3-1 slopes downward from back to front, and the lower end of the front end of the filter box body 3-1 is fixedly connected and communicated with the drain pipe 3-2, the front T-shaped chute 3-3 and the rear T-shaped chute 3- 4 are respectively arranged on the upper end of the front and rear end surfaces inside the filter box body 3-1, and the two stoppers 3-5 are fixedly connected on the top surface of the filter box body 3-1, and the two stoppers 3-5 are respectively located on the front T-shaped slide Above the groove 3-3 and the rear T-shaped ch...

specific Embodiment approach 3

[0036] Combine below Figure 1-15 To illustrate this embodiment, the filter plate slide 4 includes a front T-shaped slider 4-1, a rear T-shaped slider 4-2, a vertical plate 4-3, a door-shaped frame 4-4, and a slider chute 4-5, limit block chute 4-6 and rack 4-7; front T-shaped slider 4-1 and rear T-shaped slider 4-2 are slidingly connected to front T-shaped chute 3-3 and rear T-shaped chute respectively In the T-shaped chute 3-4, the front and rear ends of the door font frame 4-4 are respectively fixedly connected on the front T-shaped slide block 4-1 and the rear T-shaped slide block 4-2 by the vertical plate 4-3, and the door The font frame 4-4 is inclined downward from left to right, the outer end surface of the door font frame 4-4 is attached to the inner wall of the filter box body 3-1, and the front and rear end surfaces of the inner side of the door font frame 4-4 are provided with There is a slider chute 4-5, and the front and rear ends of the upper end surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com