Converter vanadium extraction process adopting top blowing oxygen lance to blow cooling agents

A technology of coolant and top blowing oxygen, used in the manufacture of converters and other directions, can solve the problems of high iron loss in semi-steel residual vanadium and slag, prolonged vanadium extraction reaction time, incomplete melting of coolant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

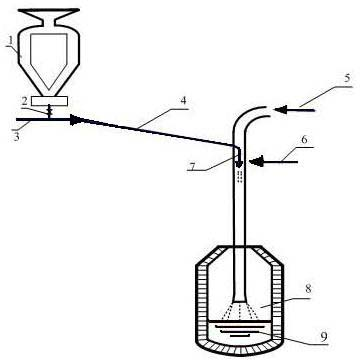

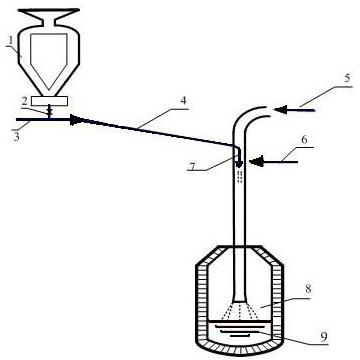

[0017] 1.30 t vanadium extraction converter

[0018] For the 30 t vanadium extraction converter, wear-resistant ceramic hoses are used to connect the powder delivery equipment with the powder inlet of the oxygen lance, and the powder supply pipeline is made of φ30×5 mm wear-resistant stainless steel pipe, which is introduced into the inner tube of the oxygen lance through a curved bend. The contraction section and throat of the oxygen lance nozzle are made of tungsten copper alloy, and the Mach number of the nozzle is 1.98. The oxygen flow rate of the oxygen inlet tube is 4000-5000 Nm 3 / h, the pressure is 0.7-0.9MPa.

[0019] Smelting process of vanadium extraction process:

[0020] In the early stage of smelting (0-30s): close the powder supply equipment, and the carrier gas flow rate is 500 Nm 3 / h;

[0021] Middle stage of smelting: spray coolant to control the temperature of molten pool at 1330°C-1380°C, turn on the powder supply equipment, and the flow rate of carrie...

Embodiment 2150

[0025] Example 2.150 t vanadium extraction converter

[0026] For the 150 t vanadium extraction converter, wear-resistant ceramic hoses are used to connect the powder delivery equipment with the powder inlet of the oxygen lance, and the powder supply pipeline is made of φ100×5 mm wear-resistant stainless steel pipe, which is introduced into the inner tube of the oxygen lance through a curved bend. The nozzle Mach number is 2.0. The oxygen flow rate of the oxygen inlet tube is 17000-19000 Nm 3 / h, the pressure is 0.7-0.9MPa.

[0027] Smelting process of vanadium extraction process:

[0028] In the early stage of smelting (0-30s): close the powder supply equipment, and the carrier gas flow rate is 1000 Nm 3 / h;

[0029] Middle stage of smelting: spray coolant to control the temperature of molten pool at 1330°C-1380°C, open the powder outlet, and the flow rate of carrier gas is 1500 Nm 3 / h, the powder flow rate is 300 kg / min, using the strong stirring effect of the powder a...

Embodiment 3300

[0033] Example 3.300 t vanadium extraction converter

[0034] For the 300 t vanadium extraction converter, wear-resistant ceramic hoses are used to connect the powder delivery equipment with the powder inlet of the oxygen lance, and the powder supply pipeline is made of φ160×5 mm wear-resistant stainless steel pipe, which is introduced into the inner tube of the oxygen lance through a curved bend. The nozzle Mach number is 2.03. The oxygen flow rate of the oxygen inlet tube is 32000-35000 Nm 3 / h, the pressure is 0.7-0.9MPa.

[0035] Smelting process of vanadium extraction process:

[0036] Early stage of smelting (0-30s): turn off the powder spraying equipment, and the carrier gas flow rate is 1500 Nm 3 / h;

[0037] Middle stage of smelting: spray coolant to control the temperature of molten pool at 1330°C-1380°C, and the flow rate of carrier gas is 3000 Nm 3 / h, the powder flow rate is 600 kg / min;

[0038] At the end of smelting (60s before the end point): In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com