Preparation method of Fe3O4@ZnO@N-C composite photocatalysis material

A technology of composite photocatalysis and raw materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as unsatisfactory cost, complicated process, and degradation ability to be improved, so as to improve photocatalysis Degradation efficiency and recycling rate, large specific surface area, and the effect of improving photocatalytic degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

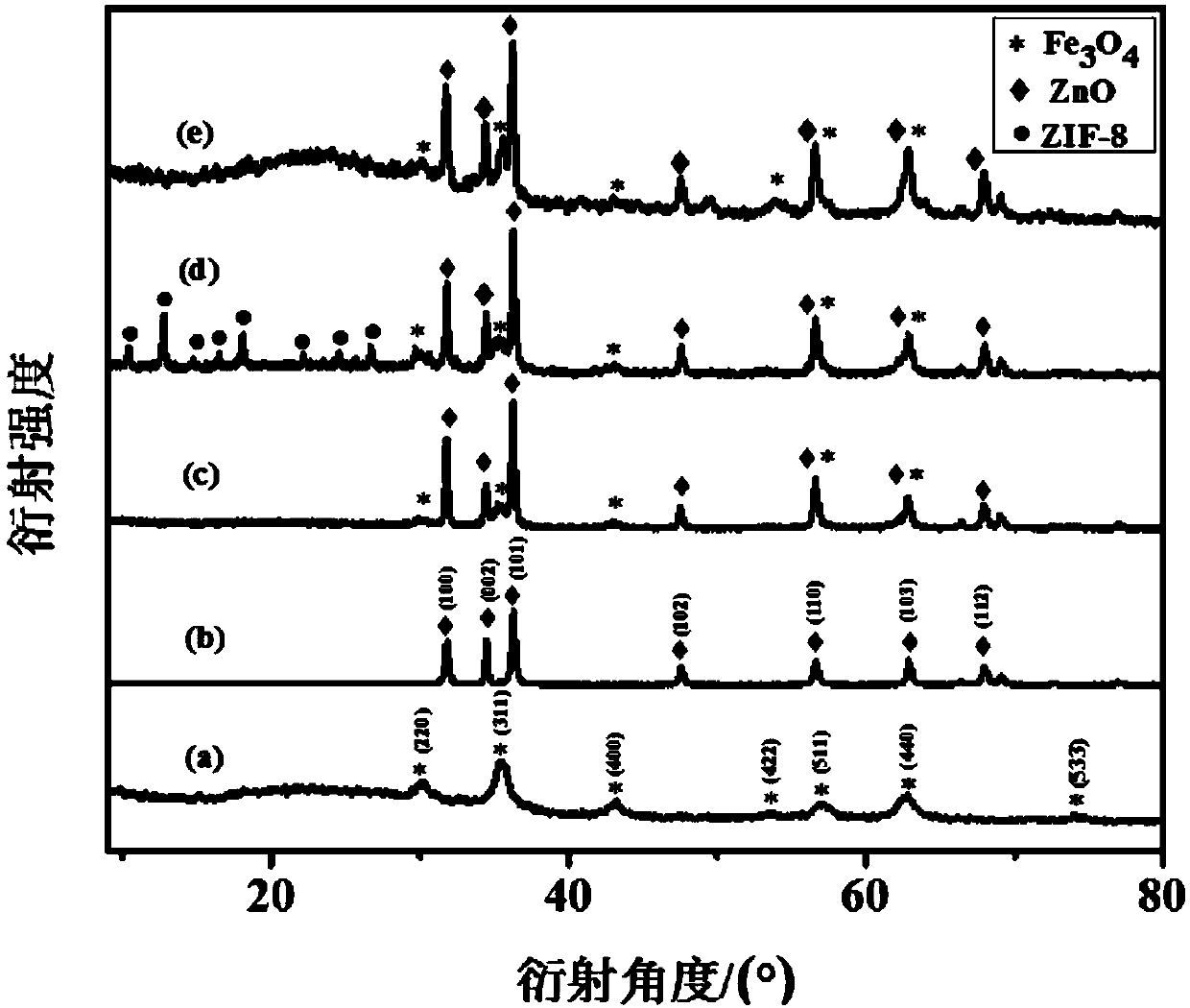

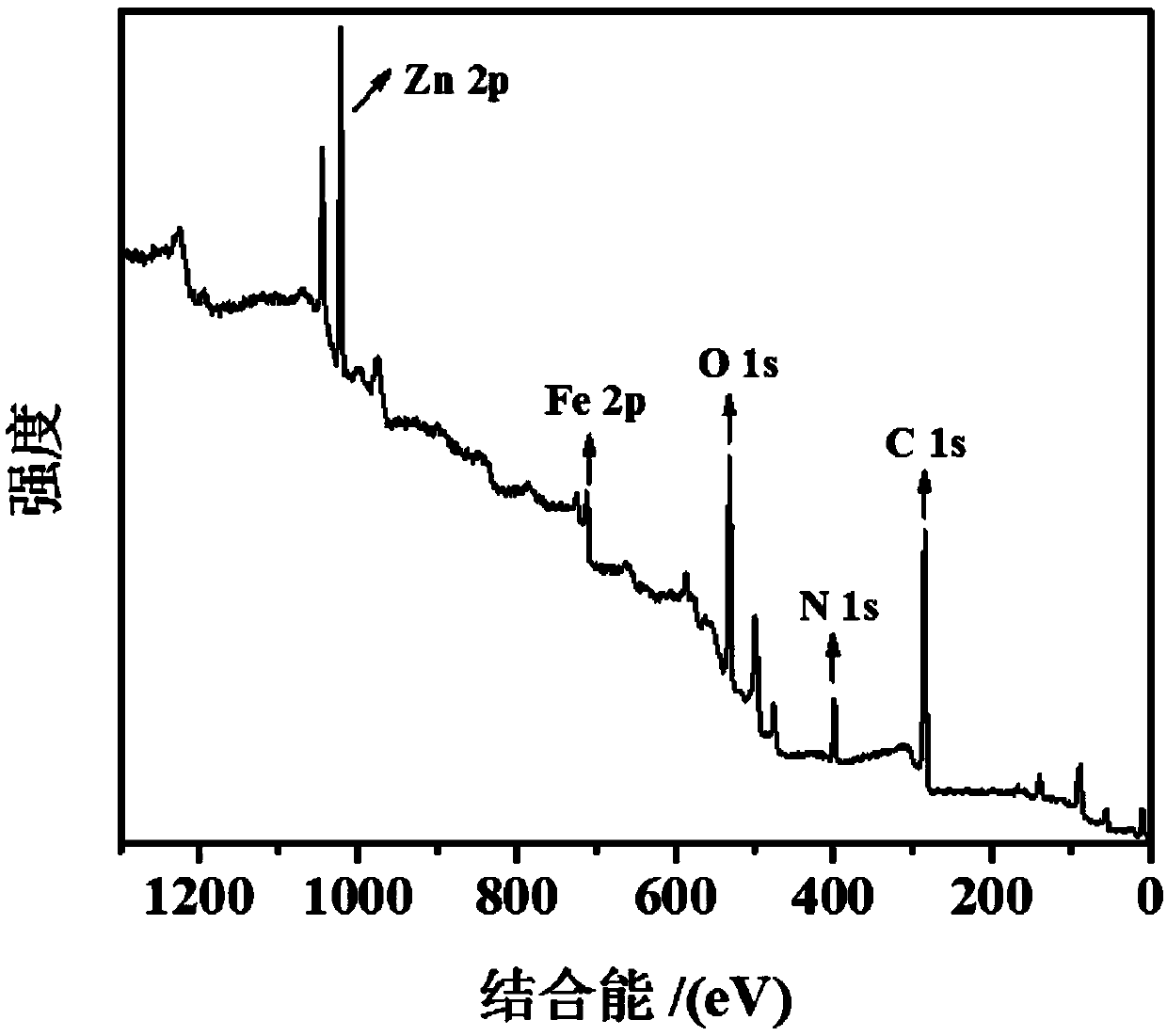

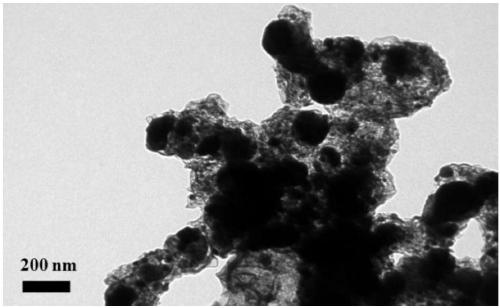

[0035] In this embodiment, see Figure 1 ~ Figure 5 , A Fe 3 O 4 The preparation method of @ZnO@N-C composite photocatalytic material includes the following steps:

[0036] a. Synthetic Fe 3 O 4 Magnetic nanoparticle materials:

[0037] Take 1.5g FeCl 3 ·6H 2 O, 0.8g of sodium citrate and 4.0g of anhydrous sodium acetate were added to 100mL of alcoholic solvent, stirred for 30min to make it completely dissolved and mixed, and then the resulting mixed solution was transferred to the reactor and heated at 160℃ for 7h. Hydrothermal reaction produces a mixture of hydrothermal products, and then magnetically separates them to obtain a black product. Then the product is washed three times with ethanol and distilled water, and then the solid obtained is vacuum dried for 8 hours to obtain Fe 3 O 4 Magnetic nanoparticle materials;

[0038] b. Synthetic Fe 3 O 4 @ZnO material:

[0039] Take 1.8g of Zn(Ac) 2 ·H 2 O and 0.6g NaOH are each dissolved in 40mL distilled water to obtain Zn(Ac) 2 ·H 2...

Embodiment 2

[0051] This embodiment is basically the same as the first embodiment, and the special features are:

[0052] In this embodiment, a Fe 3 O 4 The preparation method of @ZnO@N-C composite photocatalytic material includes the following steps:

[0053] a. Synthetic Fe 3 O 4 Magnetic nanoparticle materials:

[0054] Take 2.0g FeCl 3 ·6H 2 O, 0.6g of sodium citrate and 3.6g of anhydrous sodium acetate were added to 100mL of alcoholic solvent, stirred for 30min to make it completely dissolved and mixed, and then the resulting mixed solution was transferred to the reactor and heated at 150℃ for 8h. Hydrothermal reaction to obtain a mixture of hydrothermal products, and then magnetic separation to obtain a black product, and then the product was washed three times with ethanol and distilled water, and then the obtained solid was vacuum-dried for 8 hours, that is, Fe 3 O 4 Magnetic nanoparticle materials;

[0055] b. Synthetic Fe 3 O 4 @ZnO material:

[0056] Take 2.0g of Zn(Ac) 2 ·H 2 O and 0.7g...

Embodiment 3

[0065] This embodiment is basically the same as the previous embodiment, and the special features are:

[0066] In this embodiment, a Fe 3 O 4 The preparation method of @ZnO@N-C composite photocatalytic material includes the following steps:

[0067] a. Synthetic Fe 3 O 4 Magnetic nanoparticle materials:

[0068] Take 2.5g FeCl 3 ·6H 2 O, 0.68g of sodium citrate and 4.4g of anhydrous sodium acetate were added to 100mL of alcoholic solvent, stirred for 30min to completely dissolve and mix, then transfer the resulting mixed solution to the reactor, and heat at 190℃ for 6h. Hydrothermal reaction to obtain a mixture of hydrothermal products, and then magnetic separation to obtain a black product, and then the product was washed three times with ethanol and distilled water, and then the obtained solid was vacuum-dried for 8 hours, that is, Fe 3 O 4 Magnetic nanoparticle materials;

[0069] b. Synthetic Fe 3 O 4 @ZnO material:

[0070] Take 1.5g of Zn(Ac) 2 ·H 2 O and 0.5g of NaOH are each d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com