Method for renewable aluminum alloy iron-rich phase metamorphism

An aluminum alloy and iron-rich technology, which is applied in the field of non-ferrous metal regeneration and recovery melt processing, can solve the problems of difficult purification and removal of impurity iron, iron increase, and easy sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

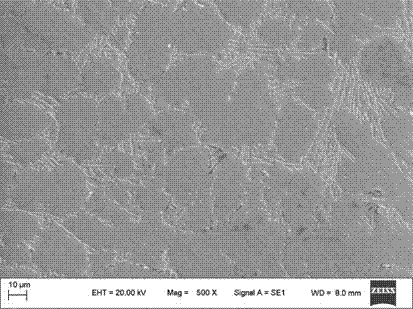

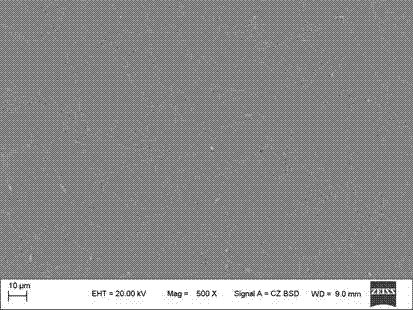

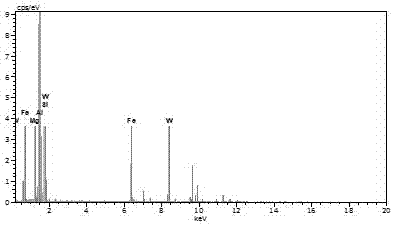

Image

Examples

Embodiment 1

[0027] Melt 800g of ADC12 aluminum alloy in a crucible resistance furnace and raise the temperature to 745±5°C. 2.4 g of AlW were pressed into the melt. Stir vigorously with mechanical stirring for 20 minutes, the stirring rod is graphite, and the stirring speed is ≥350rpm. After the stirring is finished, the temperature starts to drop, and when the temperature drops to 730°C, 2.4g of helium wrapped in aluminum foil is added, stirred continuously with a graphite rod, and refined by degassing. Keep warm for 5 minutes, take out of the oven and cast.

Embodiment 2

[0029] Put 800g of 3104 aluminum alloy into a crucible resistance furnace to melt, and raise the temperature to 745±5°C. 2.4 g of AlW were pressed into the melt. Stir vigorously with mechanical stirring for 10 minutes, the stirring rod is graphite, and the stirring speed is ≥350rpm. When the holding time is up, the temperature starts to drop. When the temperature drops to 730°C, add 4.8g of helium wrapped in aluminum foil, stir continuously with a graphite rod, and degas and refine. Keep warm for 10 minutes, take out of the oven and cast.

Embodiment 3

[0031] Melt 800g of ADC12 aluminum alloy in a crucible resistance furnace and raise the temperature to 795±5°C. 2.4 g of AlW were pressed into the melt. And use mechanical stirring to vigorously stir for 30 minutes, the stirring rod is graphite, and the stirring speed is ≥350rpm. When the holding time is up, start to cool down. When the temperature drops to 760°C, add 3g of neon gas wrapped in aluminum foil, stir continuously with a graphite rod, and degas and refine. Keep warm for 5 minutes, take out of the oven and cast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com