Patents

Literature

33results about How to "Effective anti-rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

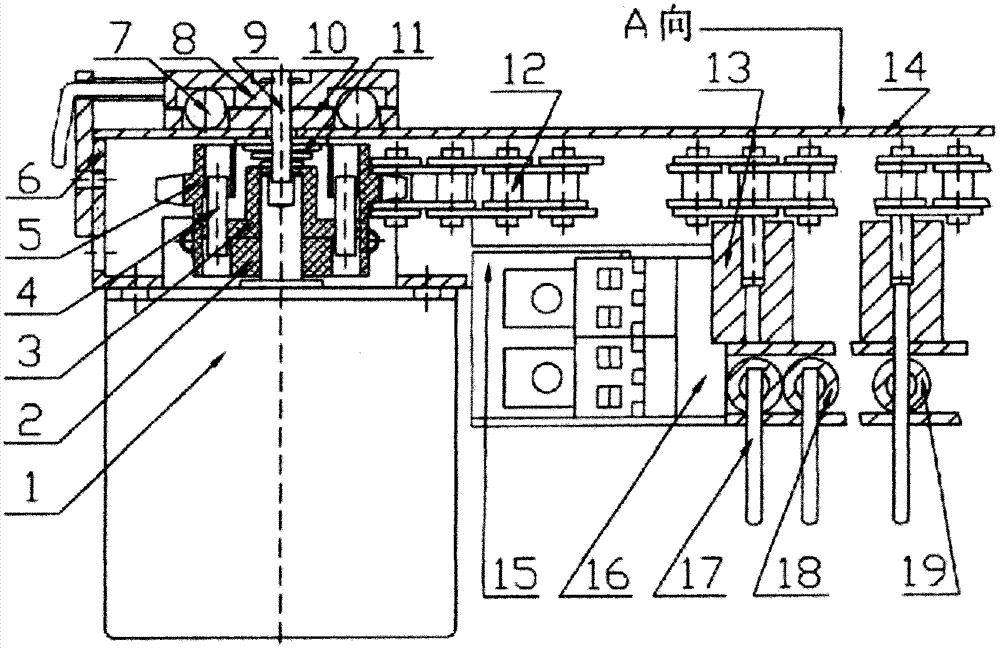

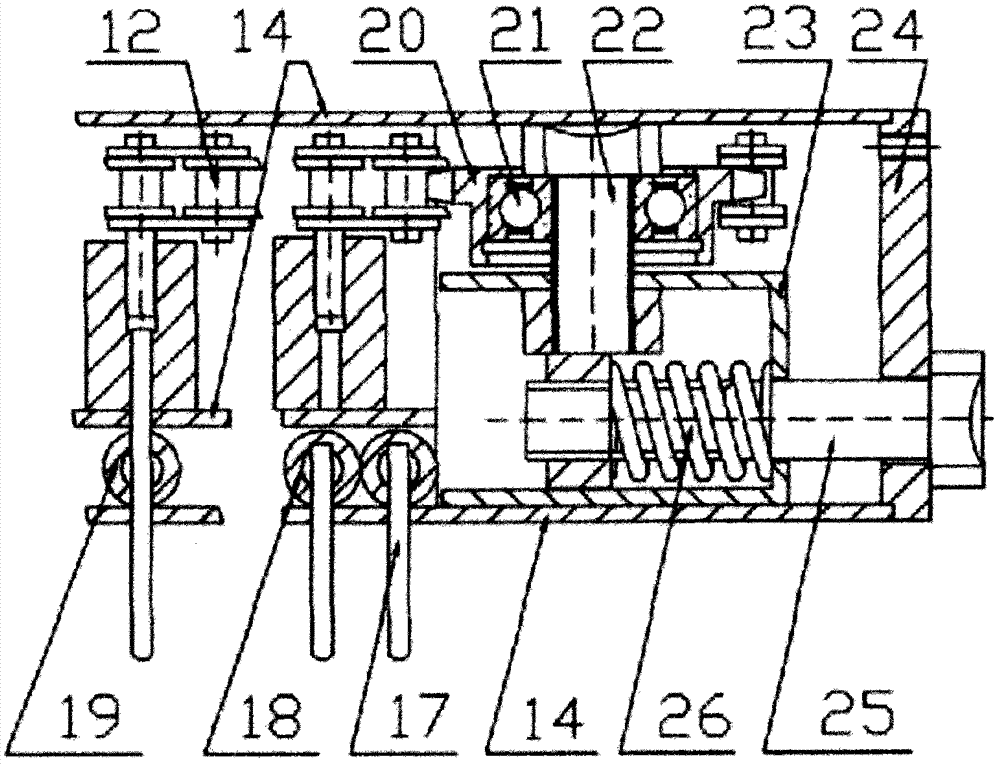

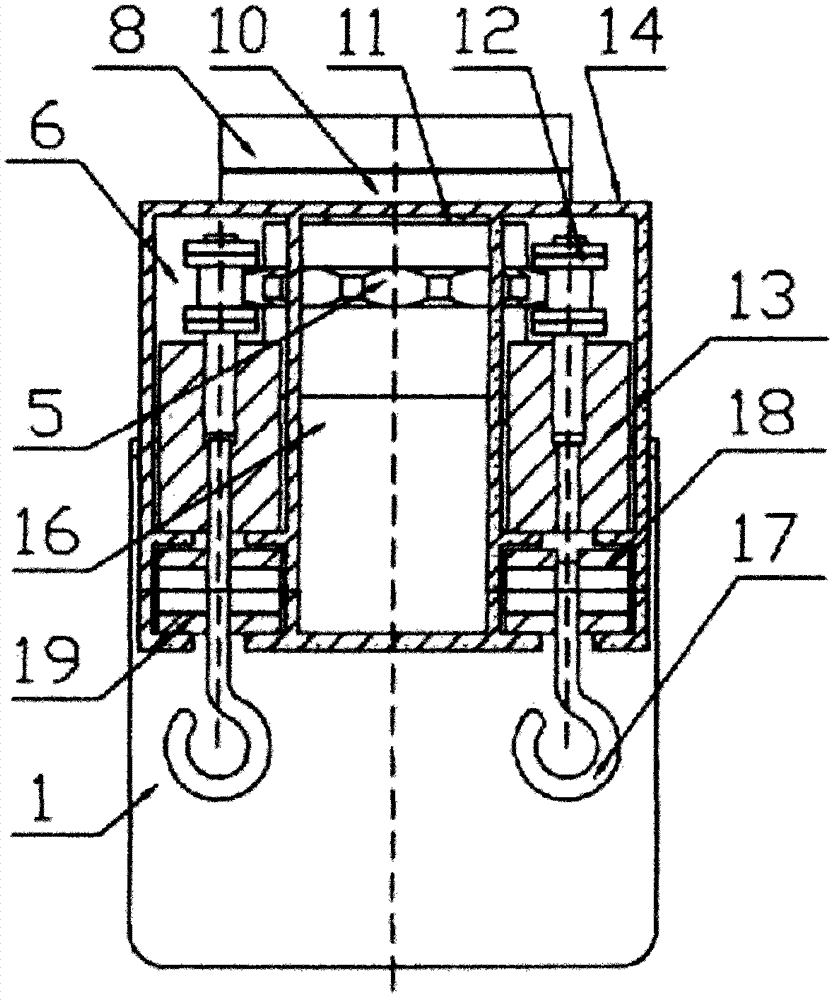

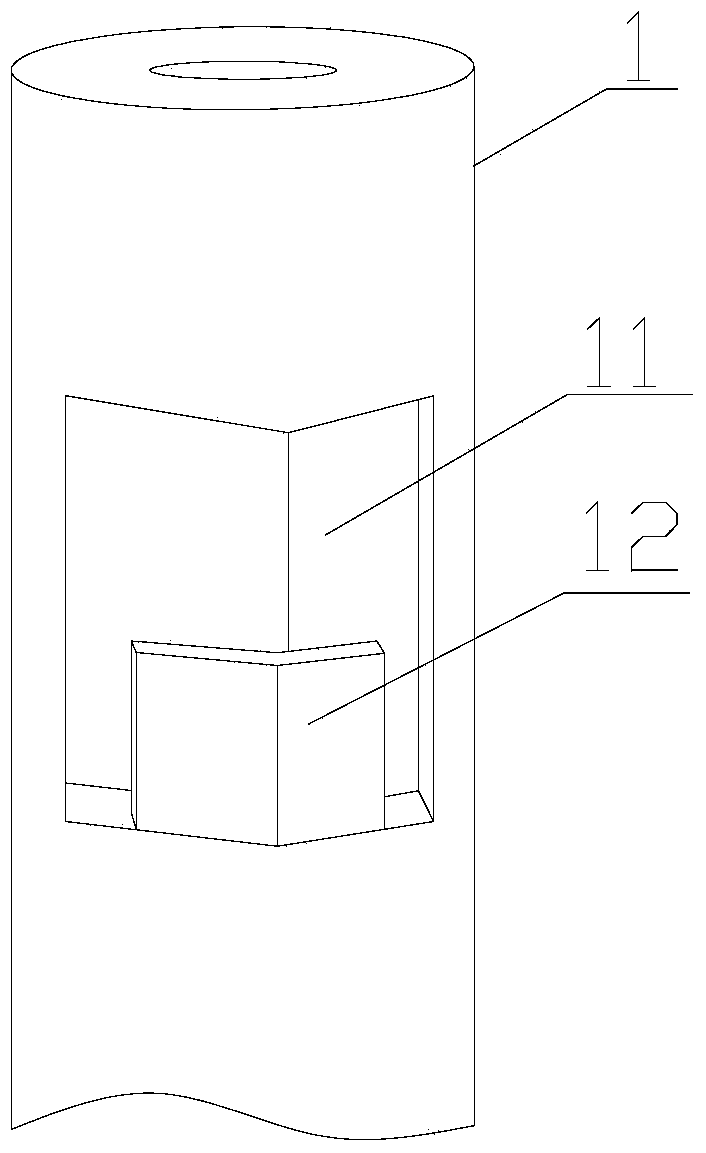

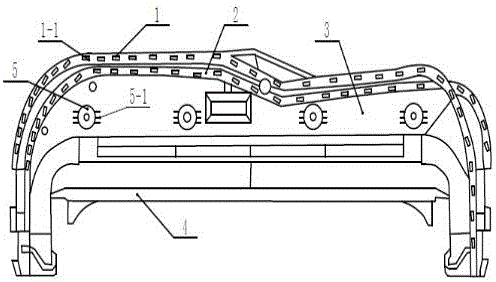

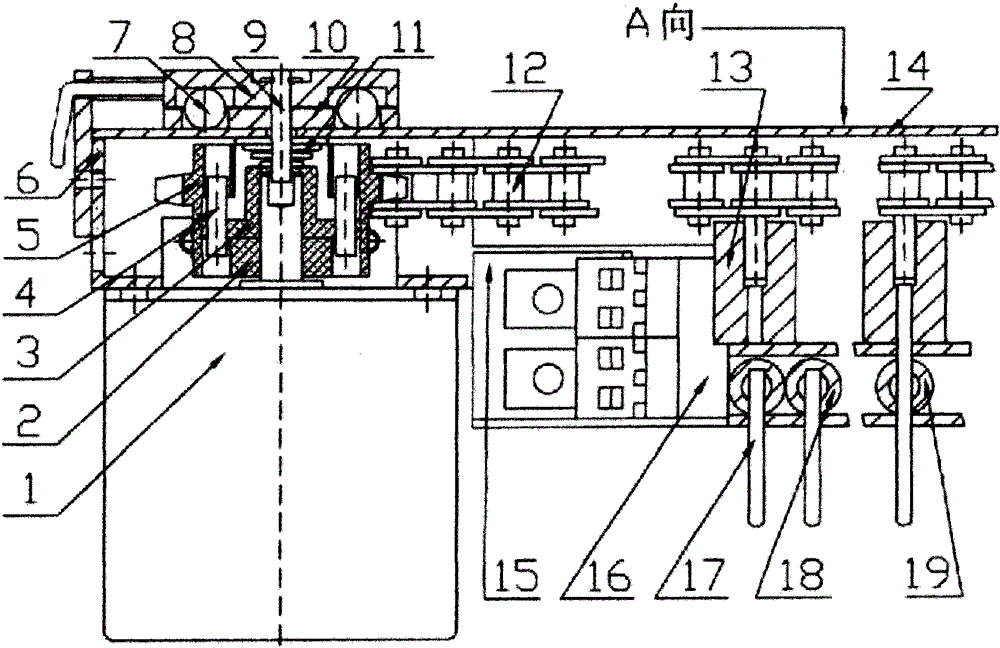

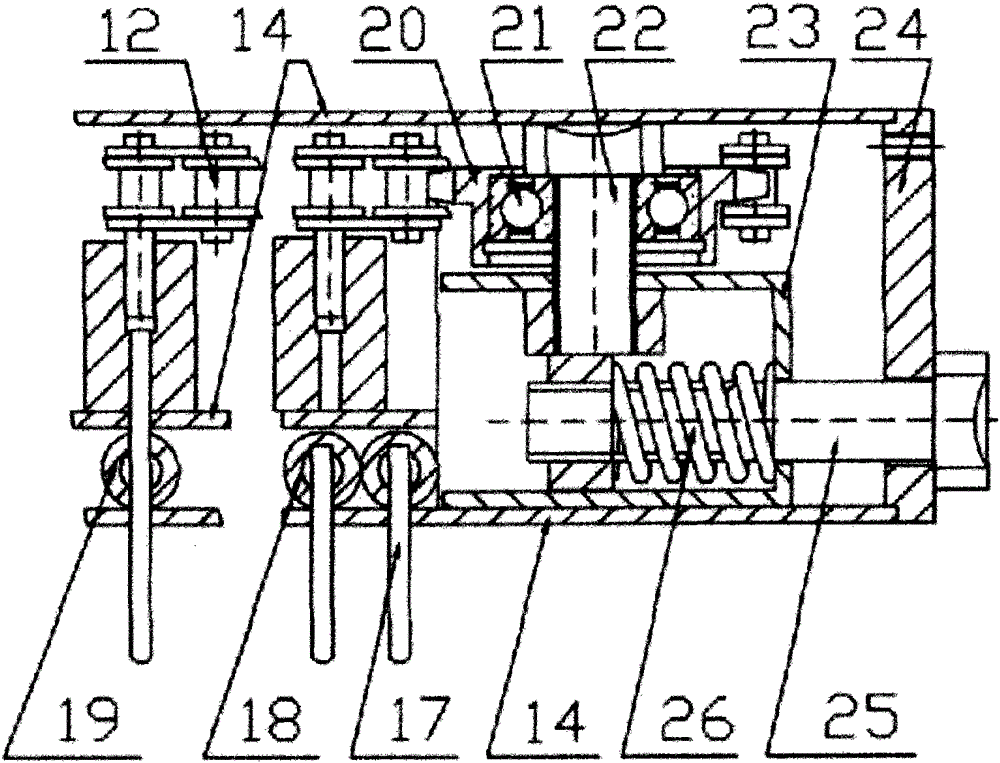

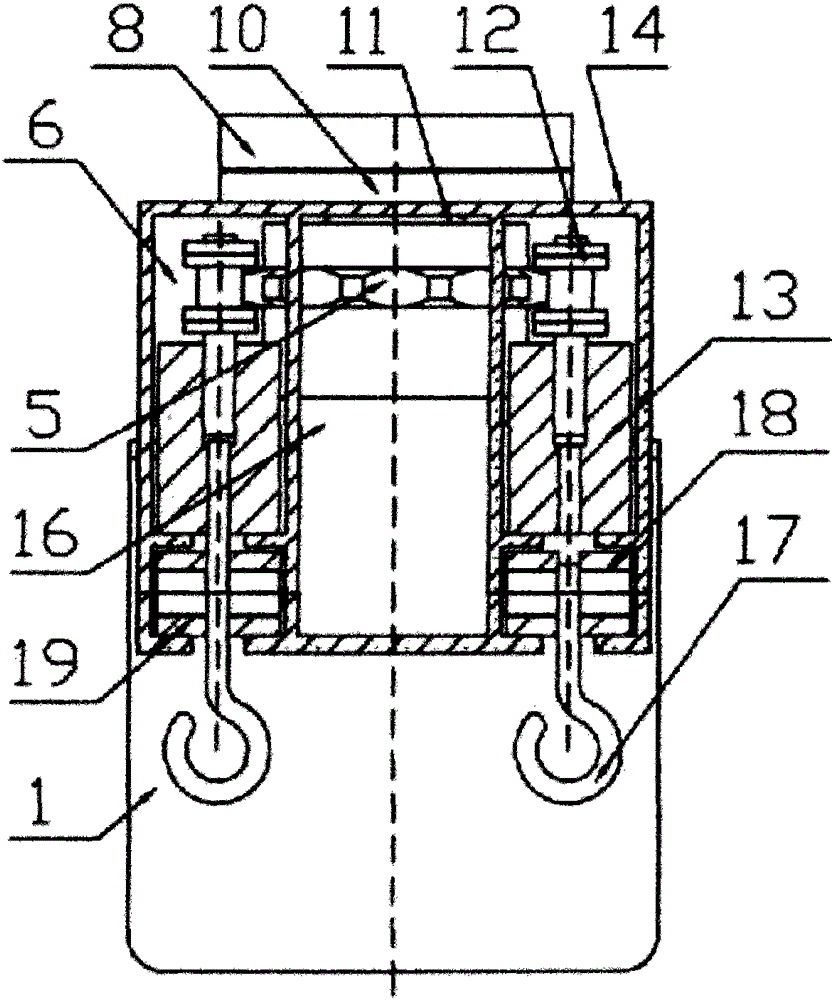

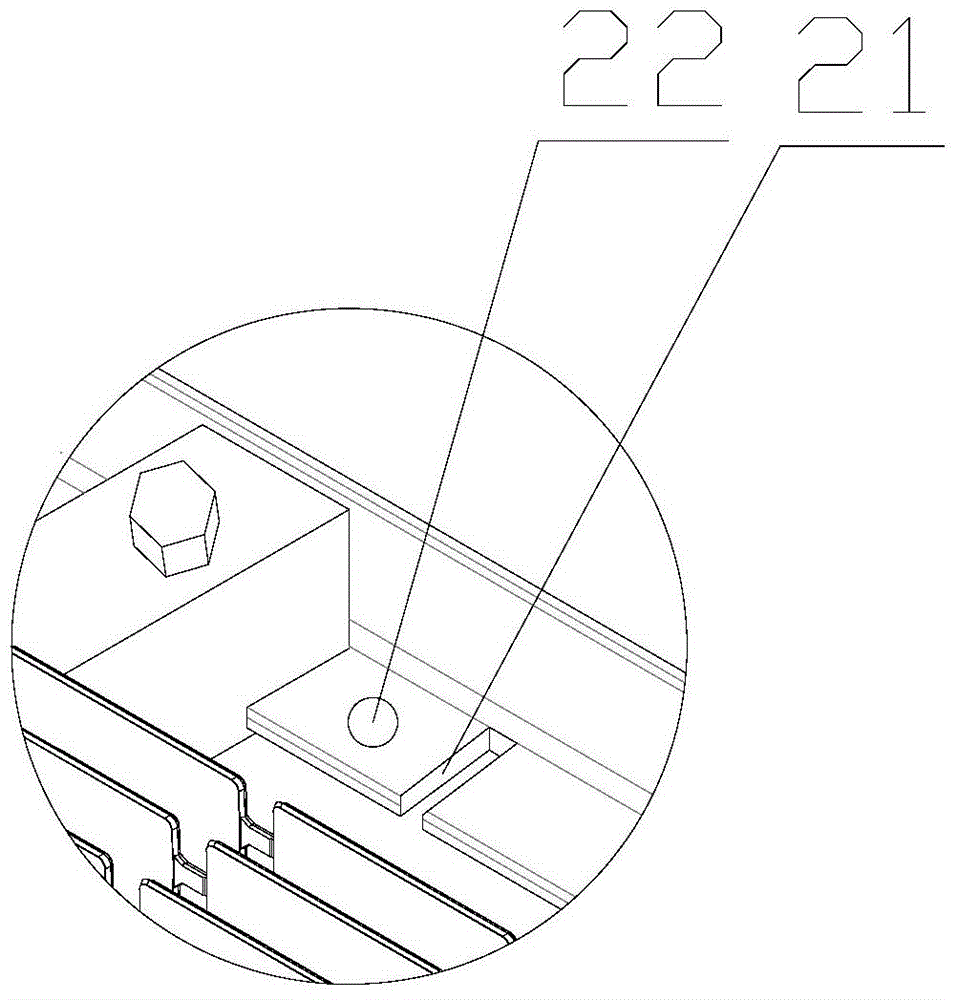

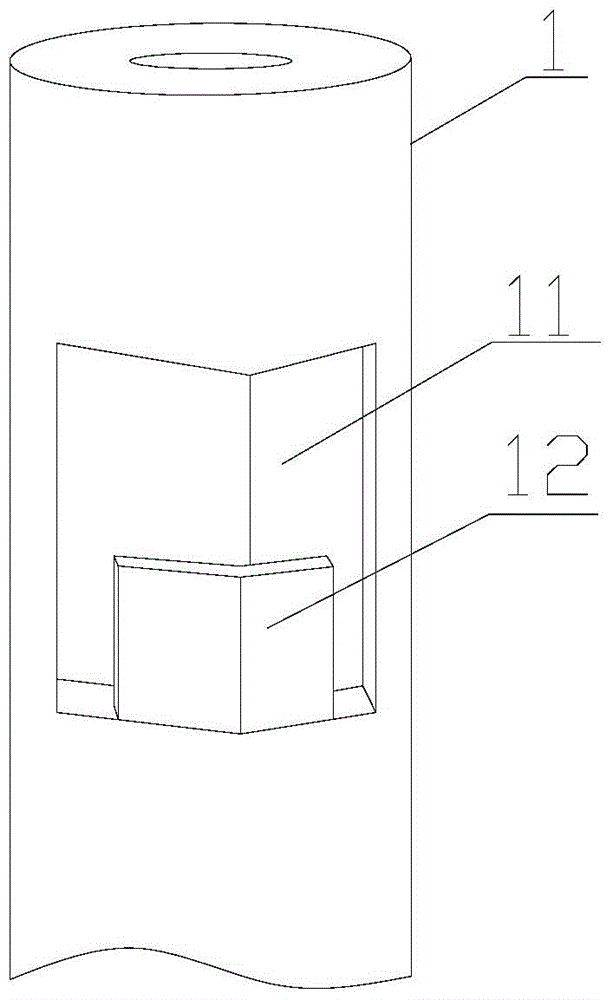

Motor-transmission device double-rail electric curtain machine capable of opening and closing two curtains in single direction or double directions

InactiveCN103494499AKeep private spaceNeat appearanceCurtain accessoriesDrive wheelReciprocating motion

The invention relates to an electric curtain machine. The electric curtain machine comprises a motor, a transmission device and a double-rail aluminum alloy machine box with the -shaped cross section and is controlled manually with one button, capable of performing limiting automatically, provided with a built-in minitype clutch device and capable of driving one curtain (a window shade or a gauze shade) or simultaneously driving two curtains (window shades or gauze shades). The electric curtain machine overcomes the defects existing in the situation that a motor and a transmission device cannot simultaneously drive double rails and two curtains. A minitype alternating current gear motor, a clutch driving device with a major functional piece arranged in a hollow wheel hub of a driving wheel, a driven wheel device with the tension capable of being adjusted, a nickel-plated chain, nylon travel idler wheels, nylon idler wheels, nylon pulleys, a travel limiting switch and stainless hooks are integrated inside and outside the double-rail aluminum alloy machine box. According to the electric curtain machine capable of being operated by hand after power failure, the chain is made to make horizontal reciprocating motor in the machine box through frontward and backward rotation of the motor so that the one or two curtains below the double rails can be driven to be opened or closed and stopped in a single direction or in double directions and can make the two curtains be opened or closed simultaneously.

Owner:王晓东

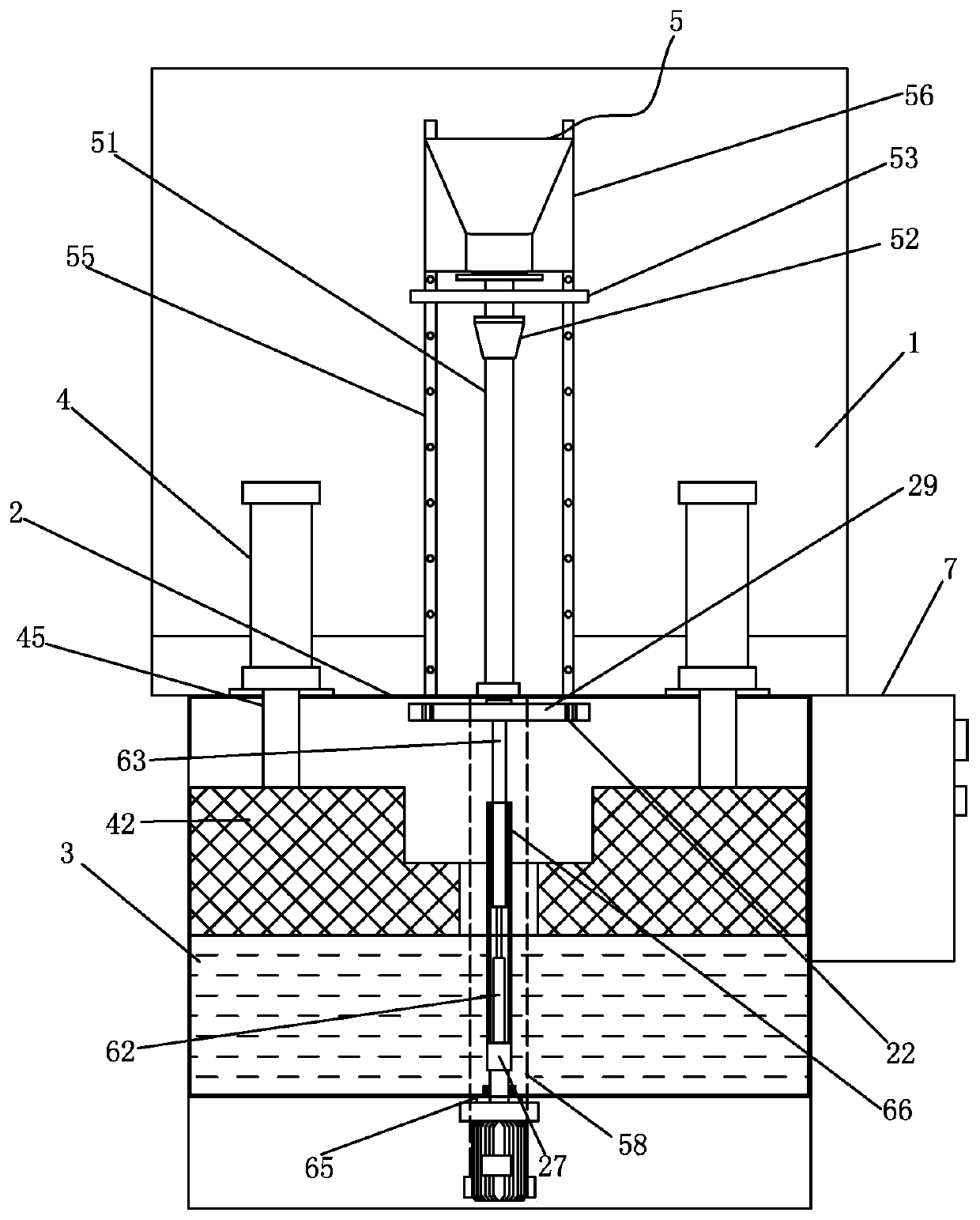

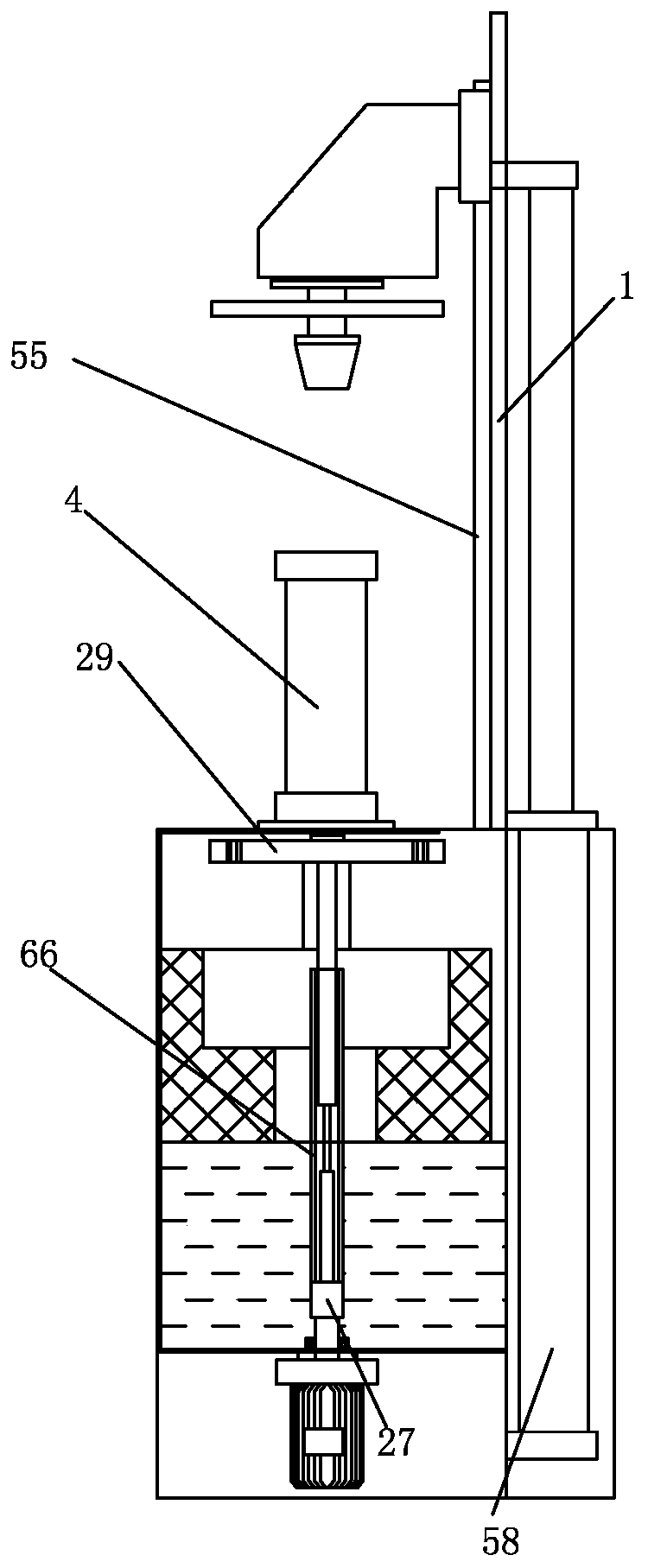

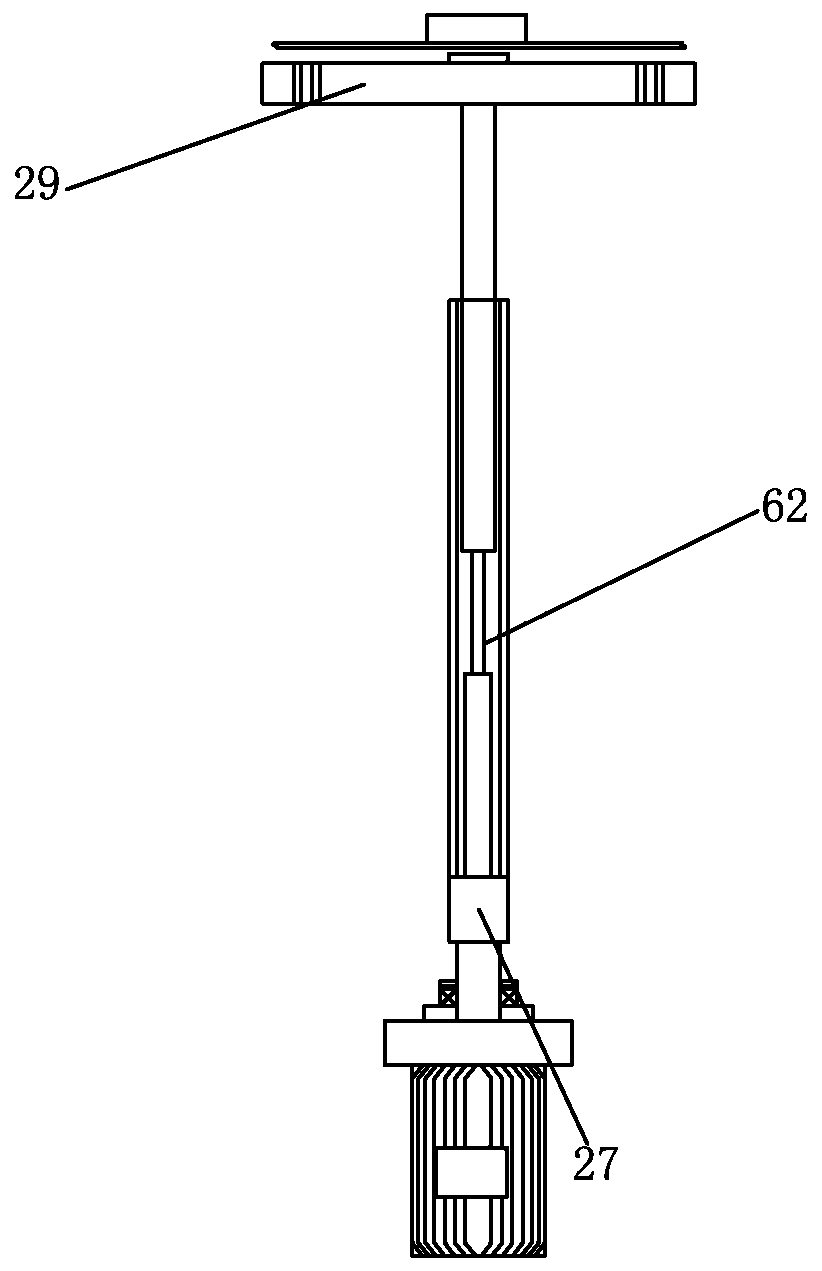

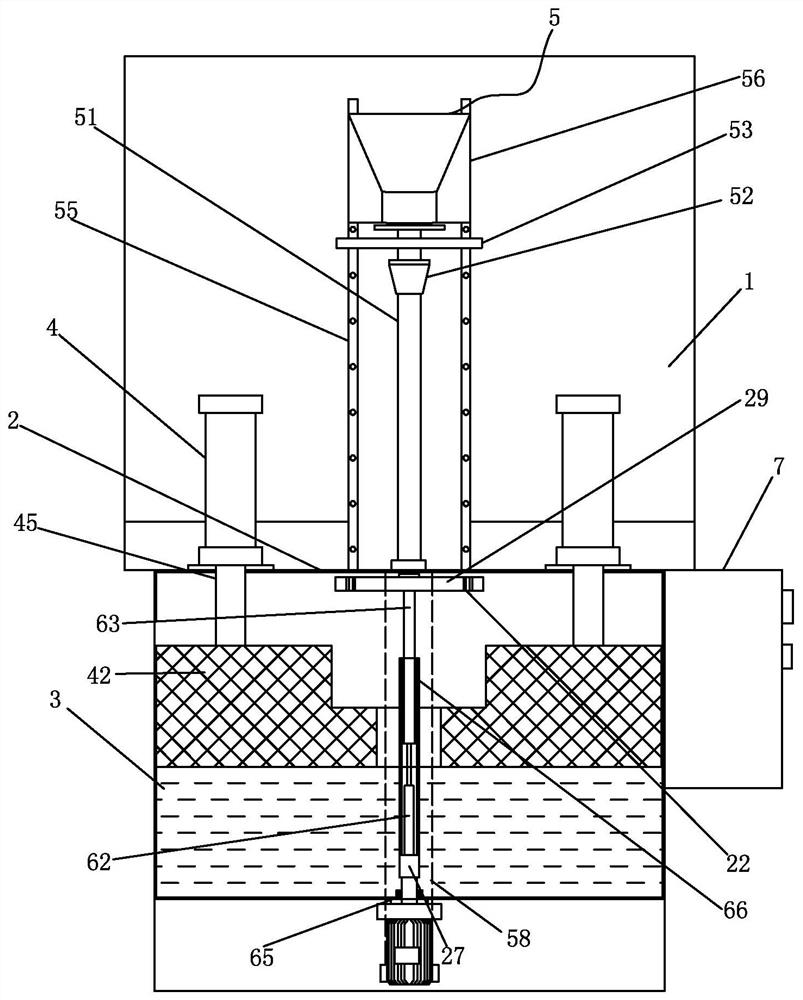

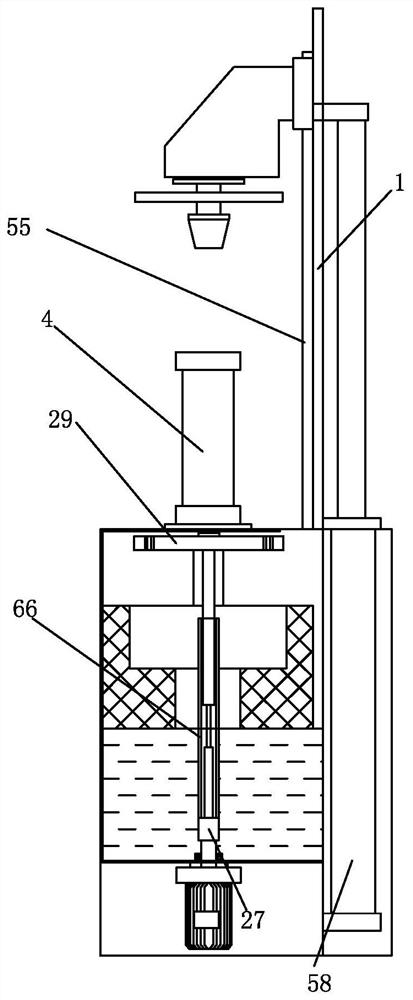

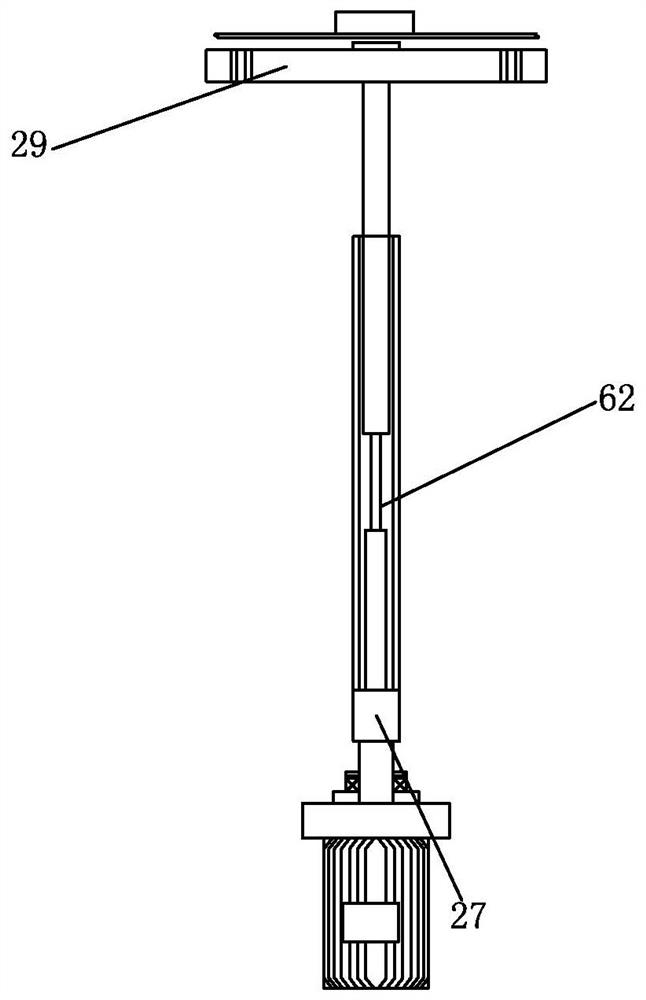

Mechanical component oil dipping and spinning-dry device

ActiveCN109876995AEffective anti-rustImprove recycling rateLiquid surface applicatorsCoatingsHydraulic cylinderMechanical components

A mechanical component oil dipping and spinning-dry device comprises a frame. The frame is provided with a work panel, an oil tank and compression air cylinders or hydraulic cylinders or electric pushrods. The work panel is arranged on the top of the oil tank. The frame is arranged on the rear side portion of the oil tank. A workpiece hole is formed in the center of the work panel of the oil tank. A rotation disc is arranged below the workpiece hole. A motor is arranged at the bottom of the oil tank. The bottom of the rotation disc is connected with the top end of a rotation shaft. The bottomend of the rotation shaft is connected with a motor output shaft. The mechanical component oil dipping and spinning-dry device is reasonable in structure and low in cost, the rotation shaft of the mechanical component oil dipping and spinning-dry device can rotate and spin surplus oil on the workpiece dry, the cyclic utilization rate of the oil is increased, and cost is saved; and the phenomenonof uneven oil coating is avoided, and rust prevention can be effectively conducted on the workpiece.

Owner:刘忠义

Iron composite cooker and surface processing method for same

ActiveCN106086774AAvoid contactExtend your lifeCooking-vessel materialsSolid state diffusion coatingFriction weldingNitrogen

The present invention discloses an iron composite cooker and a surface processing method for the same. An existing iron-aluminum-iron three-layer composite is machined by means of friction welding; when a treatment temperature is above 500 DEG C, adjacent layers will split or peel; therefore, so far, no any iron cooker manufactured by using the iron-aluminum-iron three-layer composite is developed. In the present invention, a cooker base body made from the iron-aluminum-iron three-layer composite is placed in a plasma oxynitridation furnace with a plurality of auxiliary heat sources; nitriding or / and oxynitrocarburizing treatment is / are carried out to the surface of the base body at a temperature ranging from 400 to 500 DEG C to eventually form nitride layers containing at least N-C-Fe compounds or / and oxynitride layers containing at least N-C-O-Fe compounds. The surface processing method for the iron composite cooker is capable of avoiding the adjacent layers of the iron-aluminum-iron base material from splitting or peeling; the processed nitride layers or oxynitride layers can function in effective rust protection.

Owner:湖北荣太炊具有限公司

Manufacturing method of aluminum alloy coated plates

InactiveCN103790317AHigh transparencyHigh glossCovering/liningsLamination ancillary operationsAcoustic absorptionThermal insulation

The invention relates to a manufacturing method of building plates, in particular to a manufacturing method of aluminum alloy coated plates. The building plates are resistant to corrosion and weather proof, prevent dew dropping, and have certain insulation performance. The manufacturing method includes the steps of selecting materials, preprocessing surfaces of plates, drying, coating with glue, laminating, drying, hot-pressing, and checking for storage. The product manufactured by the method has good fire resistance; detections show that the product is approved by the level B-1 of fire rating for national building materials, is fully environment friendly and pollution free, also passes environmental certification, and has the advantages of long service life, environment friendliness, fire proofing, dew prevention, corrosion resistance, acoustic absorption, light absorption, thermal insulation, high transparency, high glossiness, low haze, excellent UV barrier property, laser security, and bright decoration.

Owner:WUXI XINDAZHONG STEEL SHEET

Slide rail for automobile sliding door

InactiveCN106761100AHigh hardnessGrain refinementMolten spray coatingVehicle locksGrapheneWear resistance

The invention discloses a slide rail for an automobile sliding door. The surface of the slide rail is provided with a plasma spraying nano h-BN and graphene composite coating which is 20-30 [mu]m thick. The friction coefficient and the wear rate are decreased simultaneously through the coating, so that the low friction coefficient and excellent wear resistance are achieved, and under various loads, the wear rate is decreased by 50% or above compared with a matrix.

Owner:WUXI MINGSHENG STRONG BLOWER

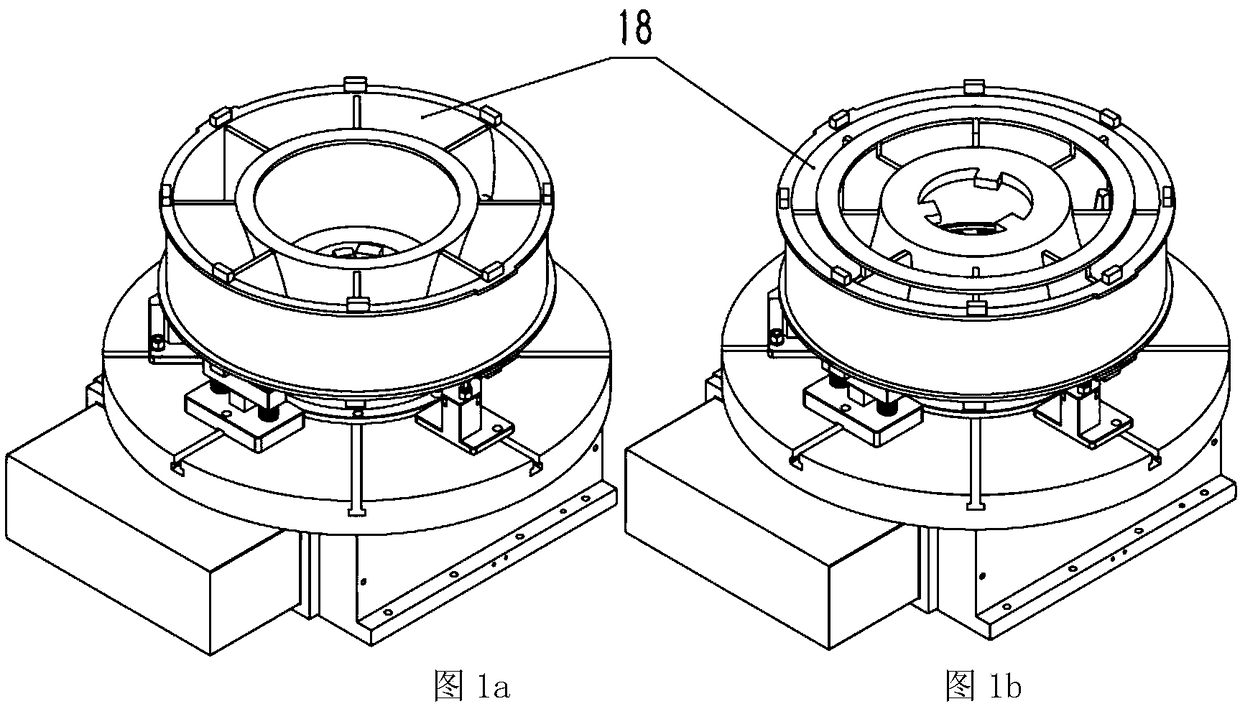

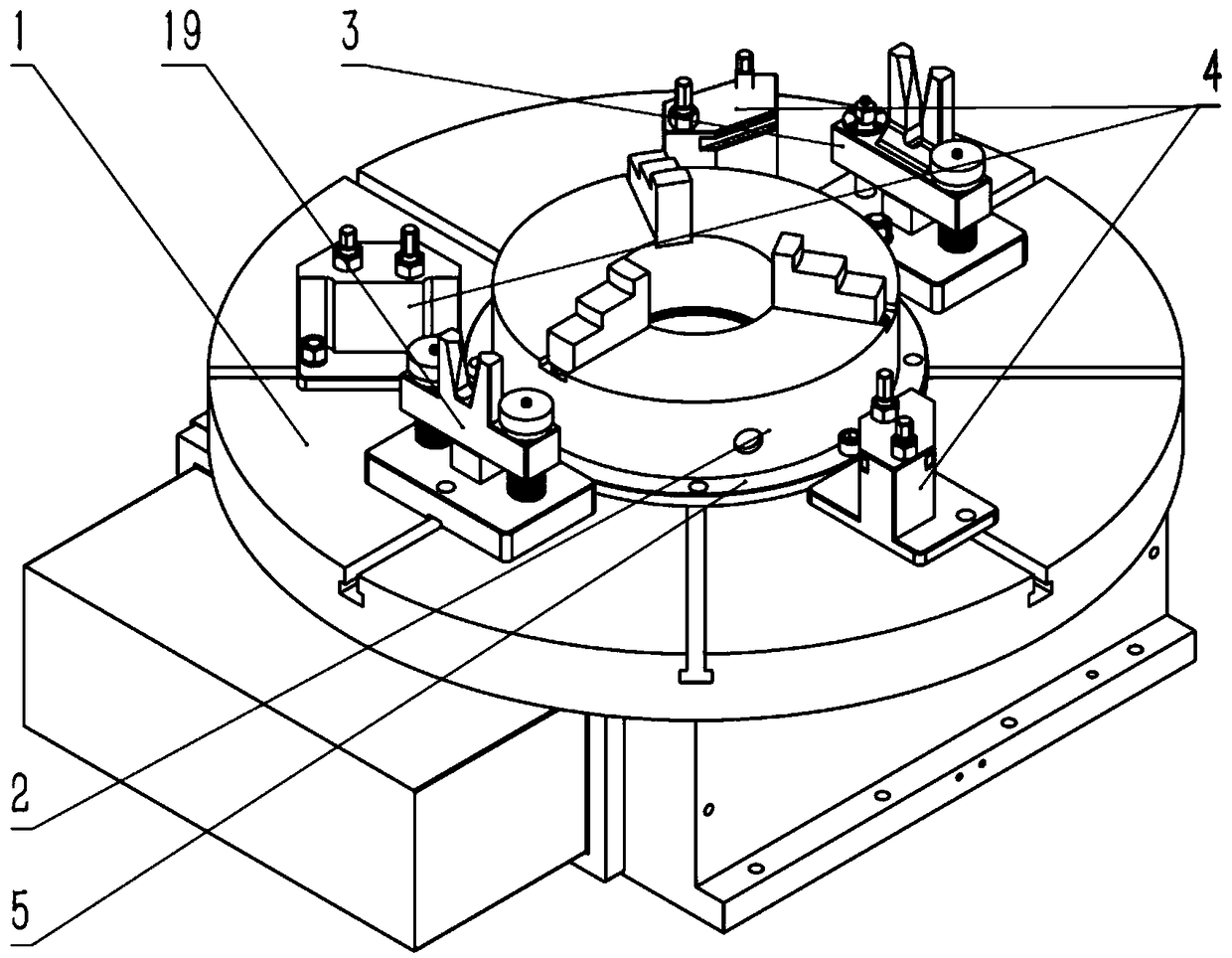

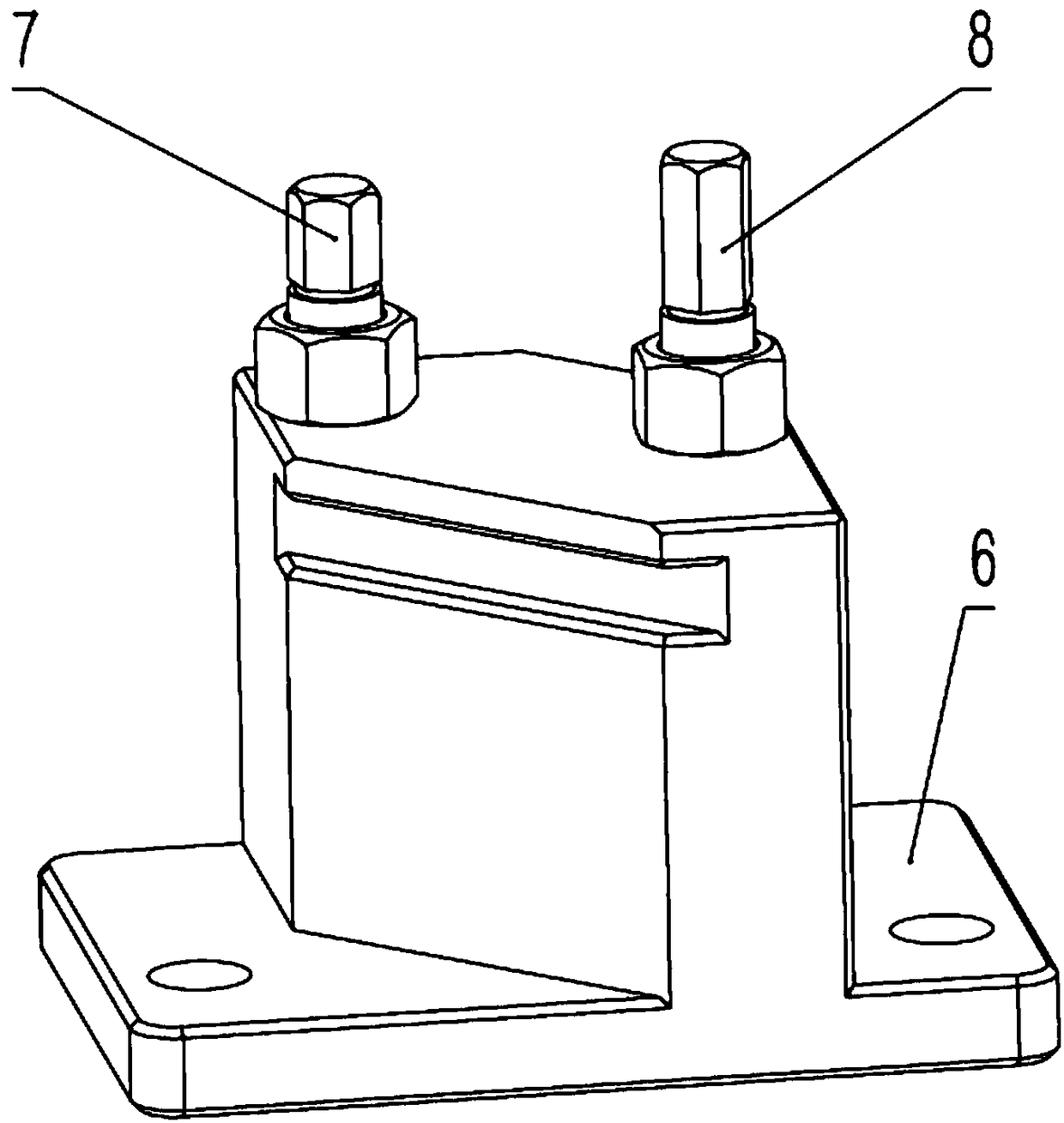

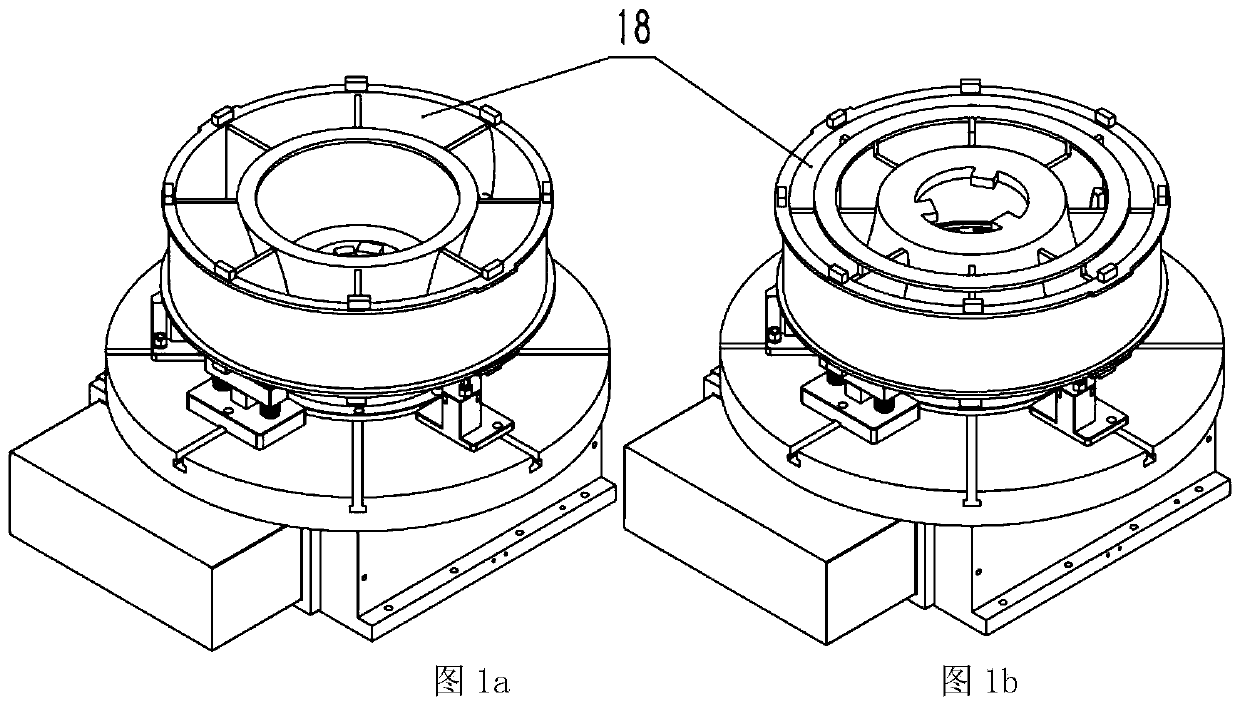

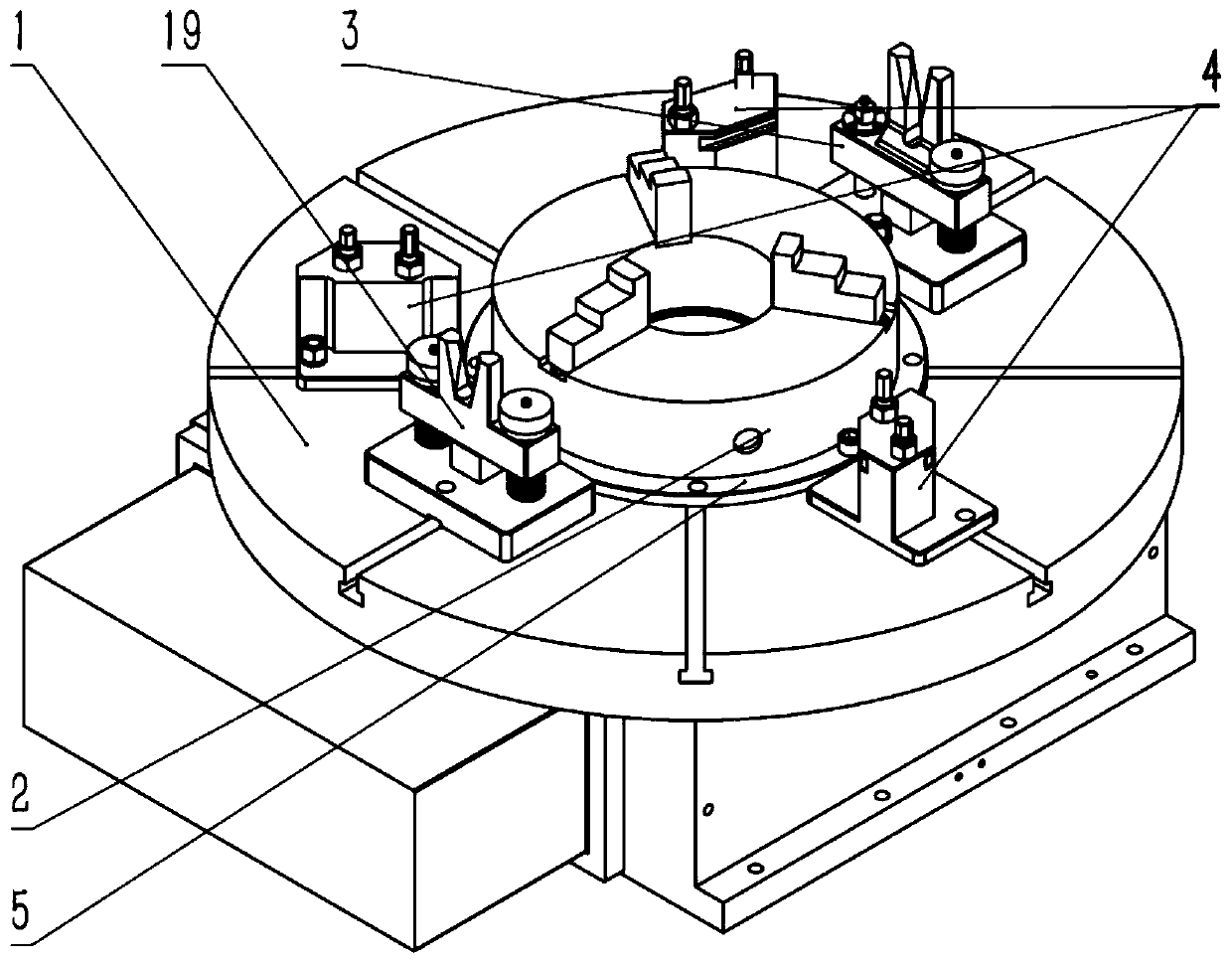

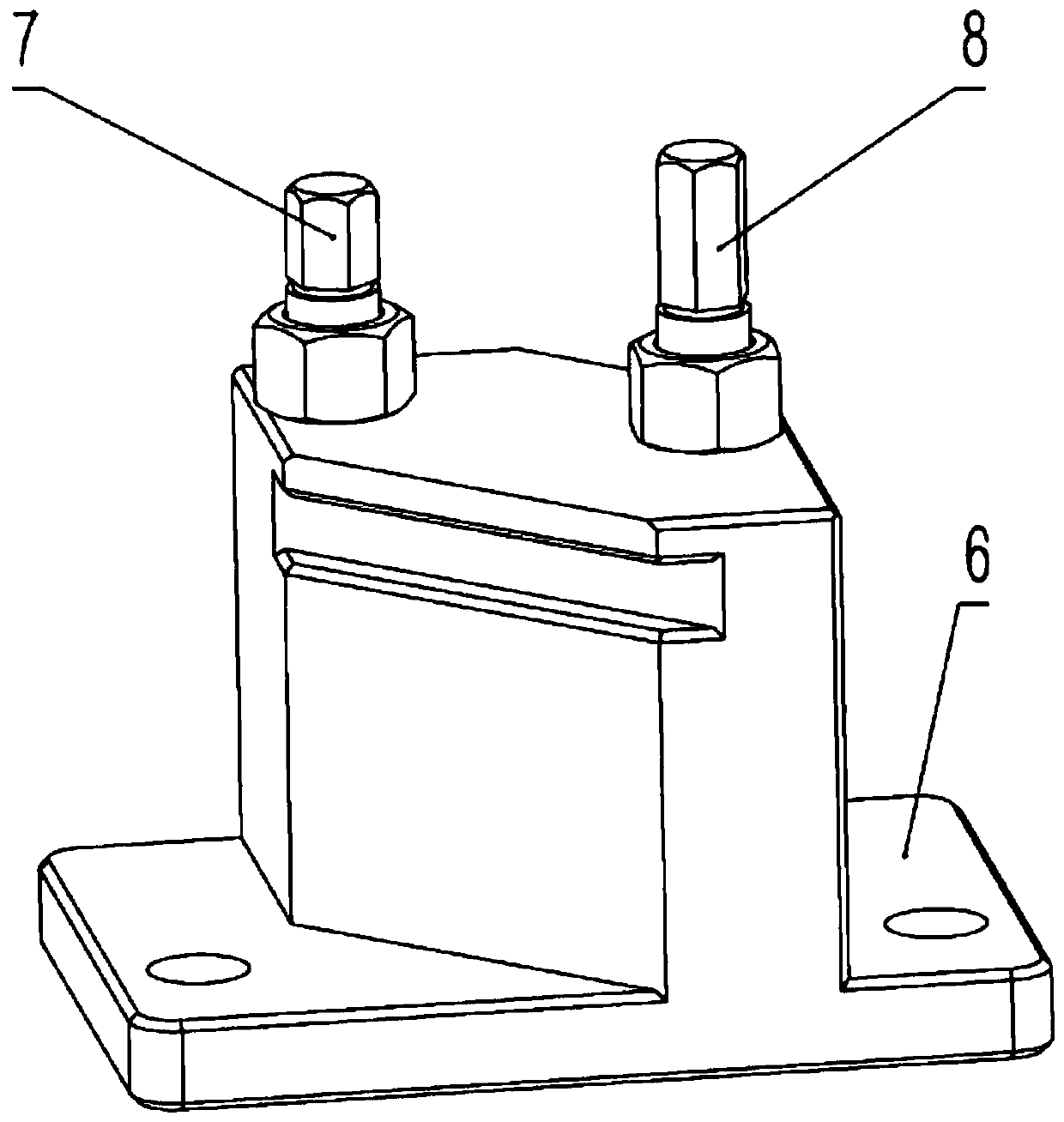

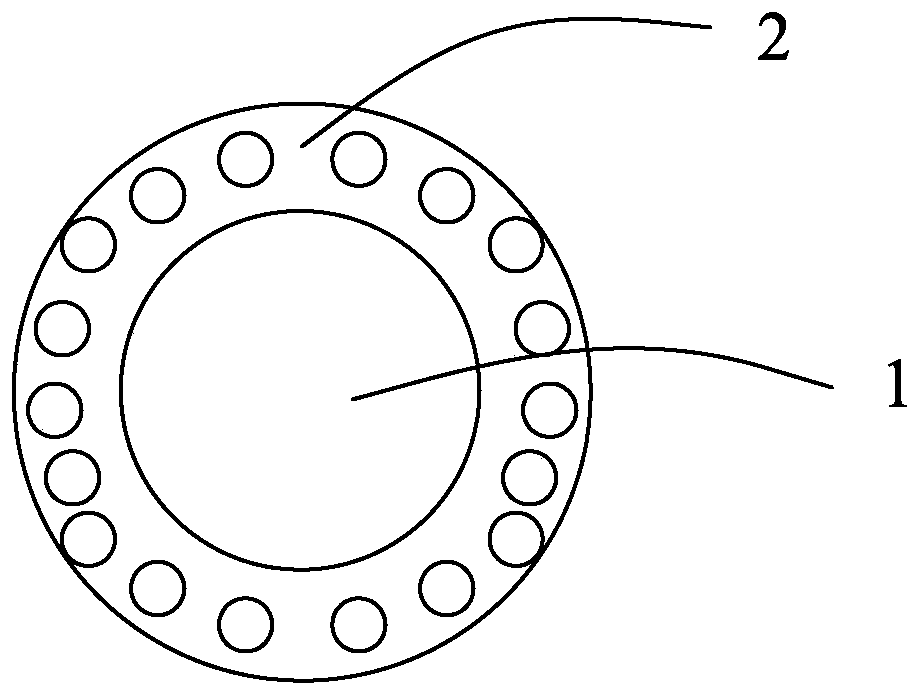

Positioning clamp used for titanium alloy ring-shaped casting and clamping method

ActiveCN109129186AAchieve circumferential positioningAchieving a centering effectGrinding work supportsRotational degrees of freedomTitanium alloy

The invention provides a positioning clamp used for a titanium alloy ring-shaped casting and a clamping method. The positioning clamp mainly comprises a rotating worktable, two floating V-shaped blockassemblies, three pin assemblies and one three-claw chuck. The titanium alloy ring-shaped casting is positioned through a clamp and is clamped to the surface of the rotating worktable. Three positioning pins are matched with the end face of the titanium alloy ring-shaped casting so as to limit the linear freedom degree of the titanium alloy ring-shaped casting in the height direction and two rotation freedom degrees. V-shaped blocks are matched with an elliptical structure on the titanium alloy ring-shaped casting to limit the circumferential rotation freedom degree of the titanium alloy ring-shaped casting. The three-claw chuck is matched with a circular inner hole of the titanium alloy ring-shaped casting to limit the linear freedom degree of the titanium alloy ring-shaped casting on the plane, and clamping is achieved. By means of the clamp, complete positioning of the titanium alloy ring-shaped casting is achieved, the clamp is suitable for front-face and back-face clamping of thetitanium alloy ring-shaped casting, and a servo motor arranged in a rotating worktable can be controlled to make the rotating worktable drive the clamp and the titanium alloy ring-shaped casting to rotate to the designated angle after clamping is completed.

Owner:WUHAN UNIV OF TECH

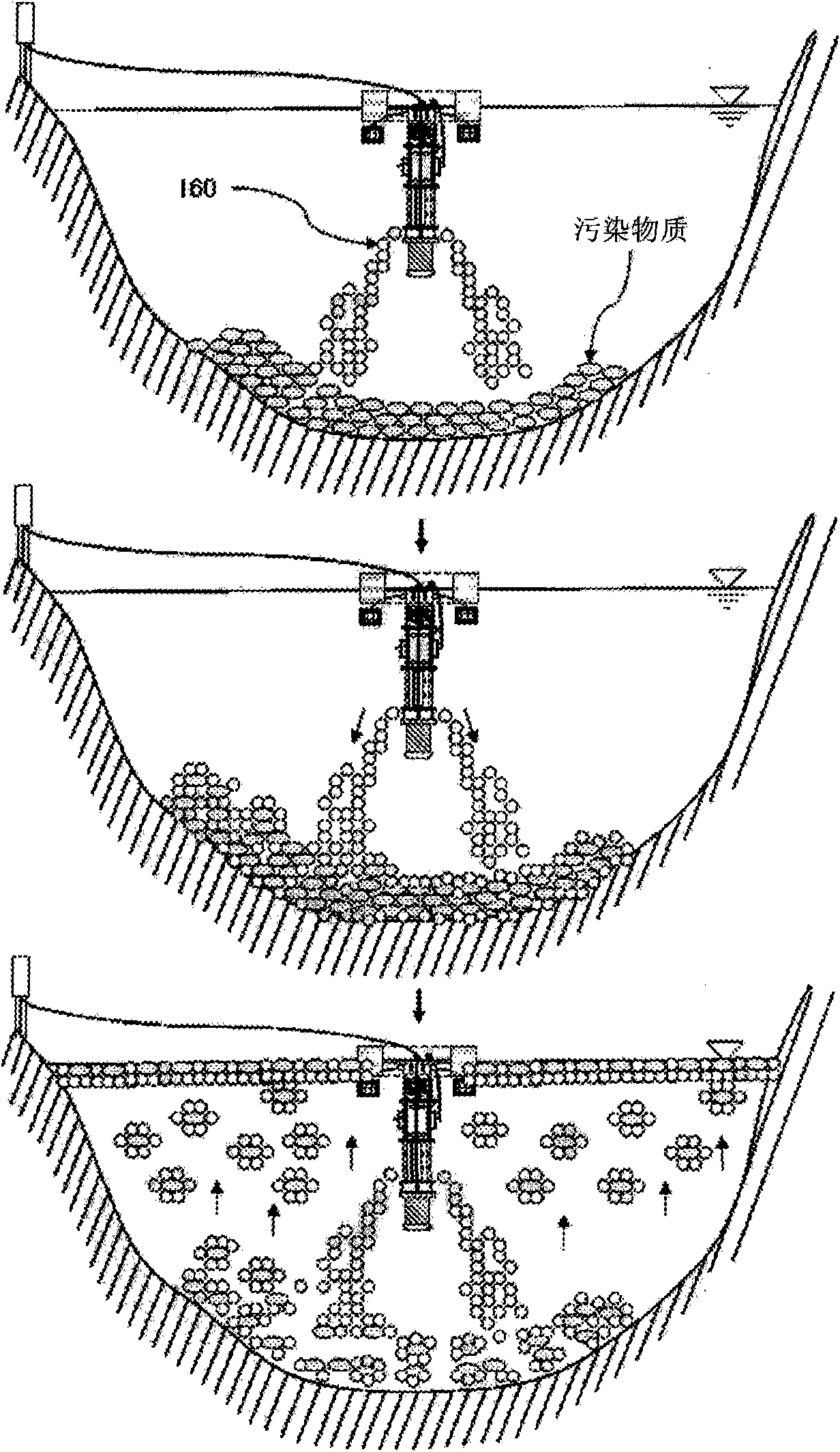

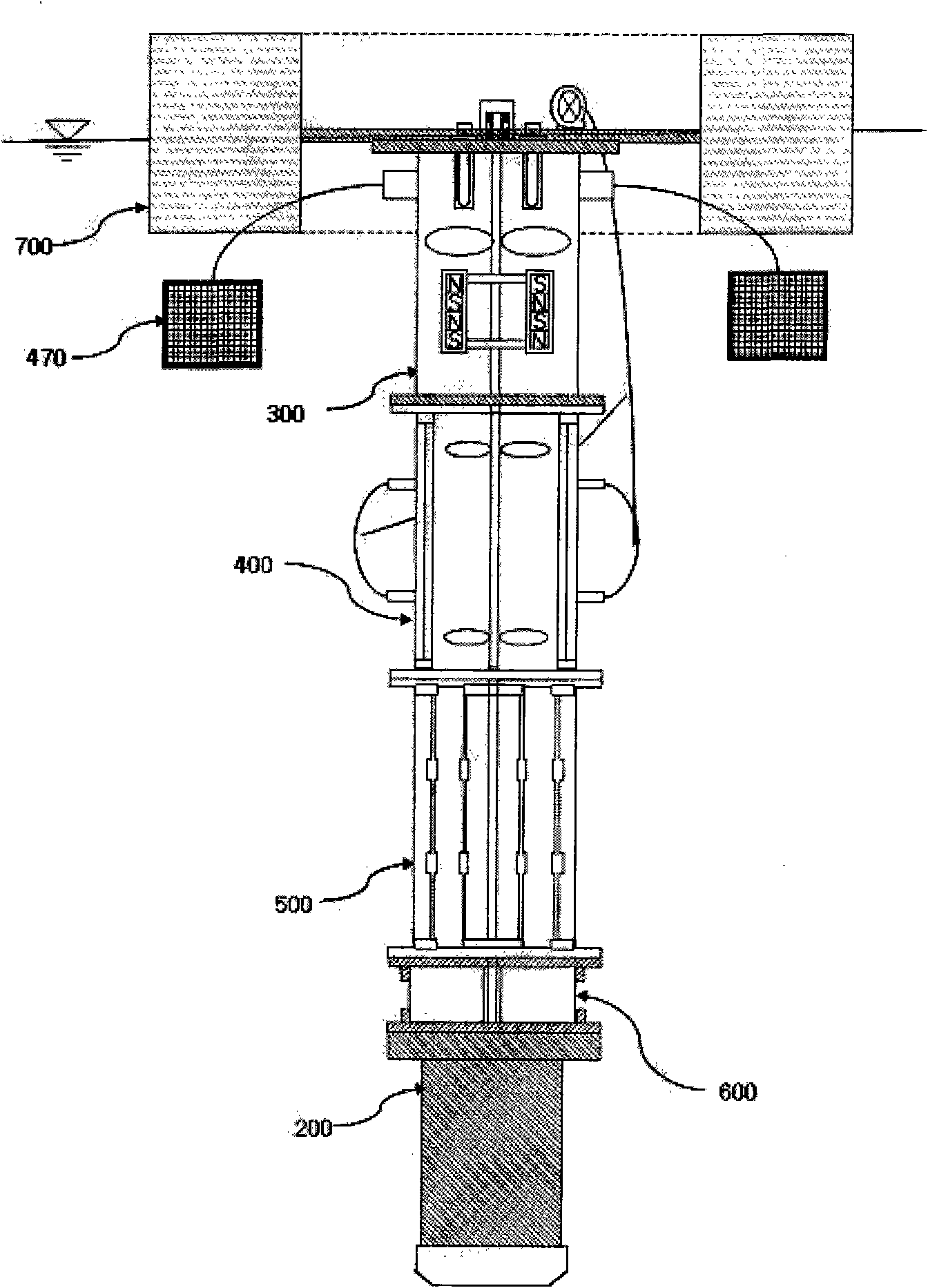

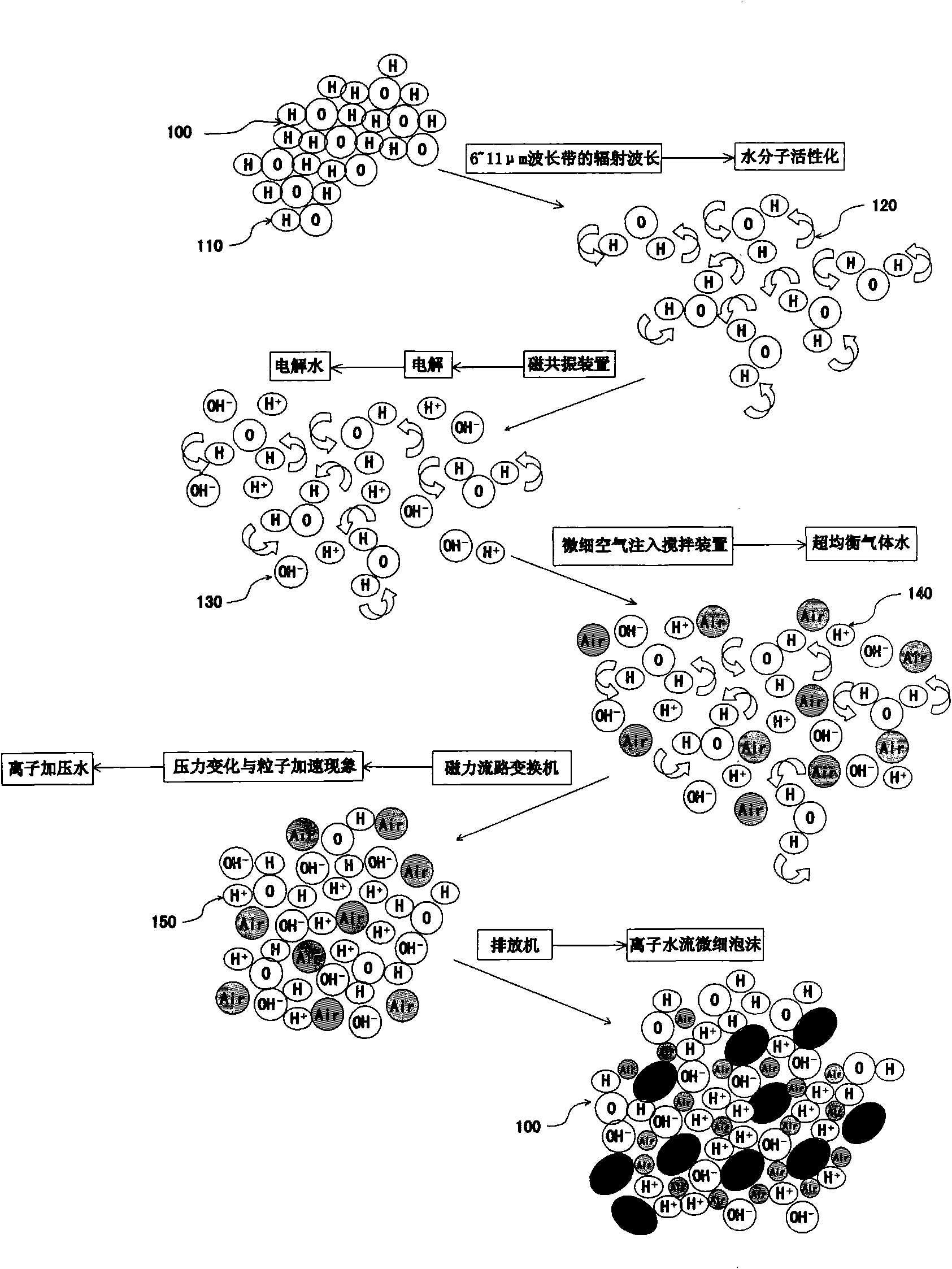

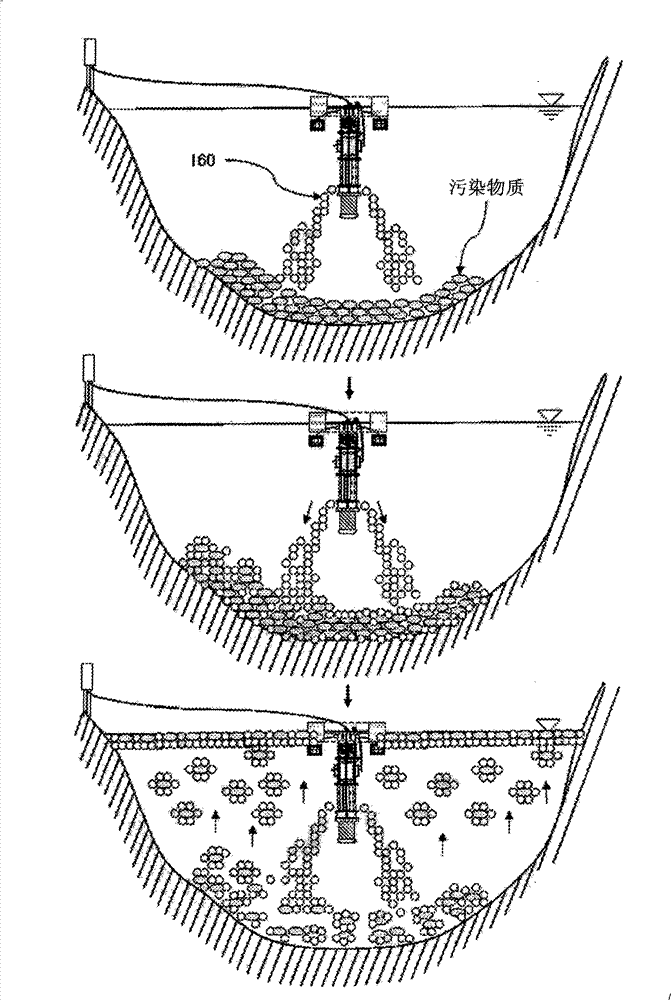

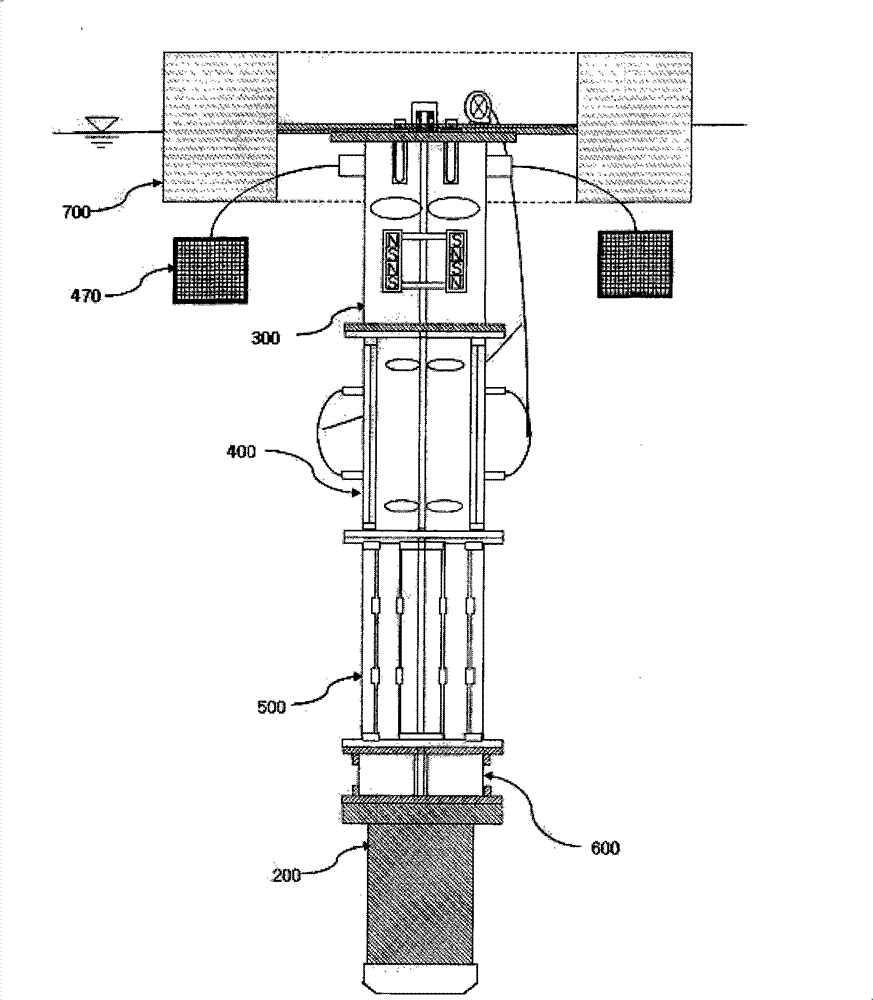

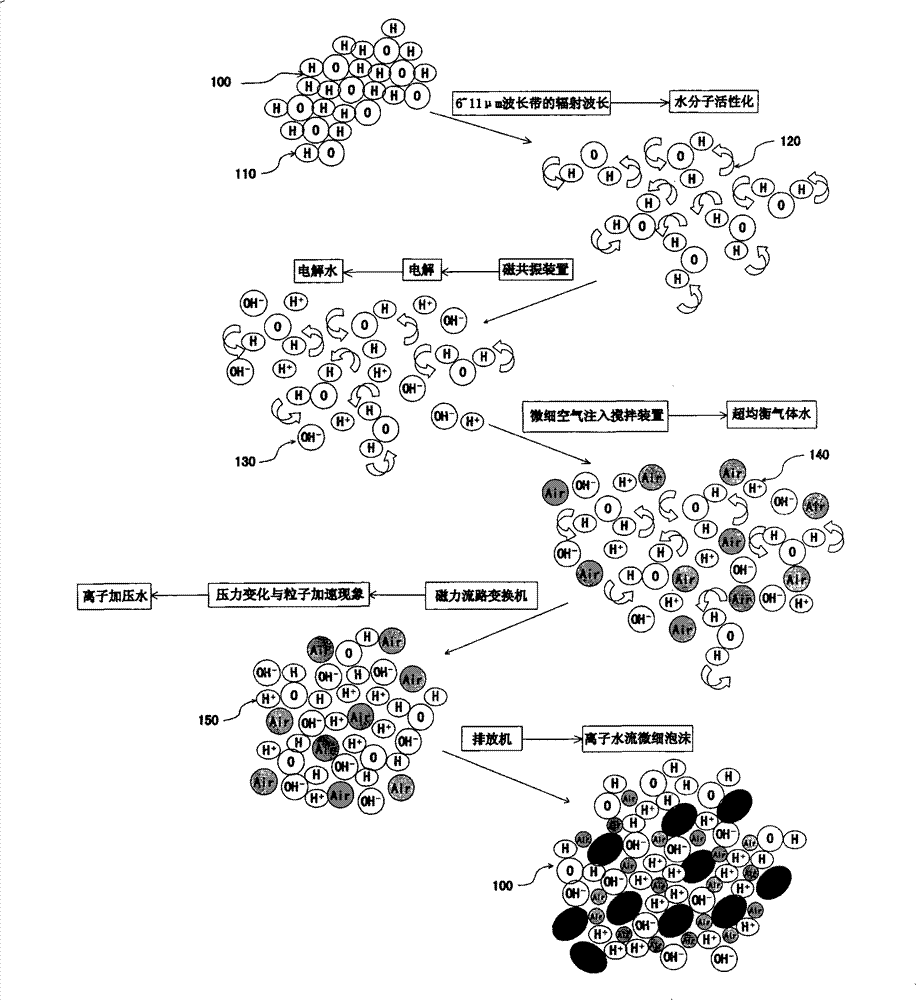

Ionized current superfine foam generating device and ionized current superfine foam generating method using device

InactiveCN101643257AEasy to eluteEasy to removeWater/sewage treatment by flotationFiltrationMolecular cluster

The invention relates to an efficient ionized current superfine foam generating device and an ionized current superfine foam generating method using the device, which can purify the water quality of polluted water. The system and the method are characterized in that inflow water in a molecular cluster state is naturally absorbed and then stirred, and the active motion of water molecules is activated by radiation wavelengths which are emitted from a far infrared lamp and have water molecule resonance absorption wavelengths; by means of the self-heating and resonance phenomenon produced by high-speed rotation of the water molecules, the electrolysis operation is carried out without an electrode, and then superfine foams sheared when flowing through a micro-pore filtration core collide with the electrolyzed water; the foams are effectively dissolved and stored by using a flow path and pressure change caused by sectional area change of the flow path and generate ion pressurized water; theion pressurized water is prayed to the water in an atmospheric pressure state to generate ionized current superfine foams; and then the superfine foams and polluted substances float up the water together so as to effectively purify the polluted water.

Owner:郑浩荣

Manufacturing method of hot-dip galvanized coated plates

InactiveCN103790309AExtended service lifeEnvironmentally friendlyLamination ancillary operationsCovering/liningsAcoustic absorptionThermal insulation

The invention relates to a manufacturing method of building plates, in particular to a manufacturing method of hot-dip galvanized coated plates. The building plates are resistant to corrosion and weather, prevent dropping of dews, and have certain thermal insulating property. The manufacturing method includes the steps of selecting materials, preprocessing the surfaces, drying, coating with glue, laminating, drying, hot-pressing, and checking for storage. Products manufactured by method are well fireproof; detections show that the products are approved by the level B-1 of national building materials fire rating, are fully environment friendly and free of pollution, also pass environmental certification, and have the effects of long service life, environment friendliness, fire proofing, dew prevention, corrosion resistance, acoustic absorption, light absorption, thermal insulation, high transparency, high glossiness, low haze, excellent UV barrier property, laser security, and bright decoration.

Owner:WUXI XINDAZHONG STEEL SHEET

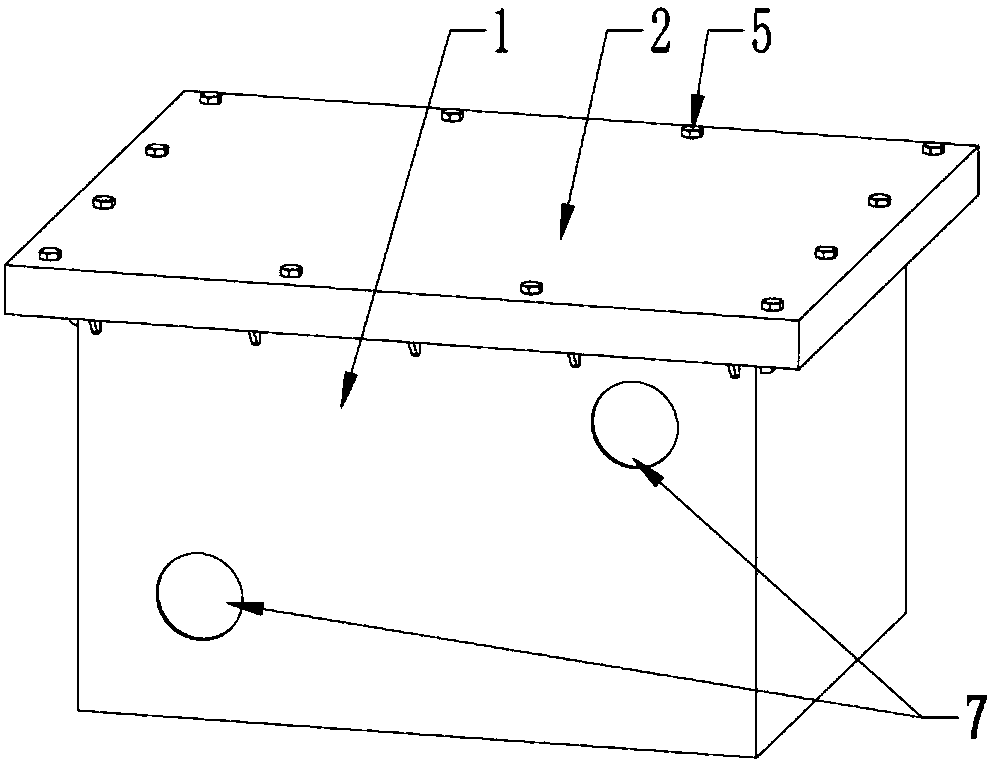

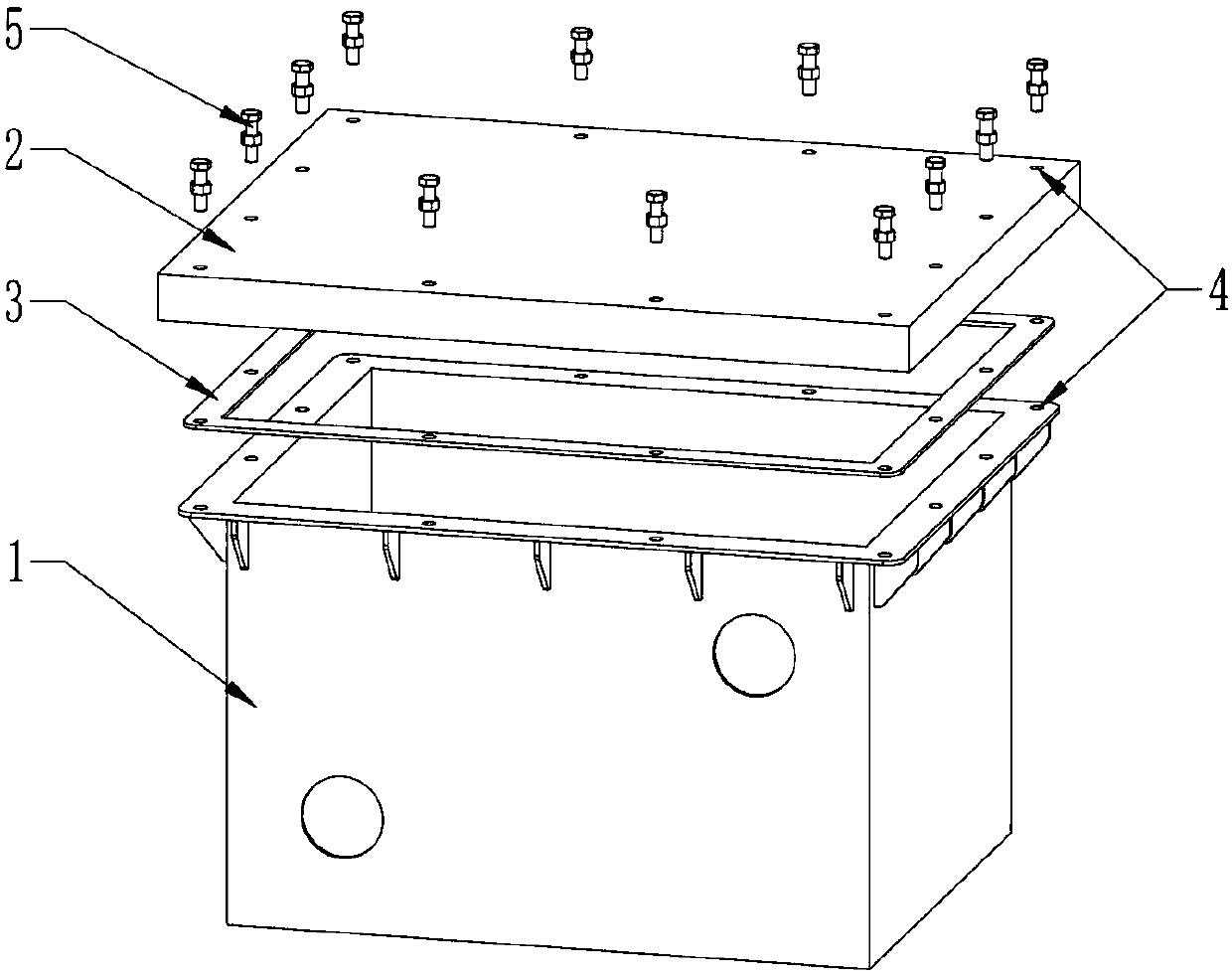

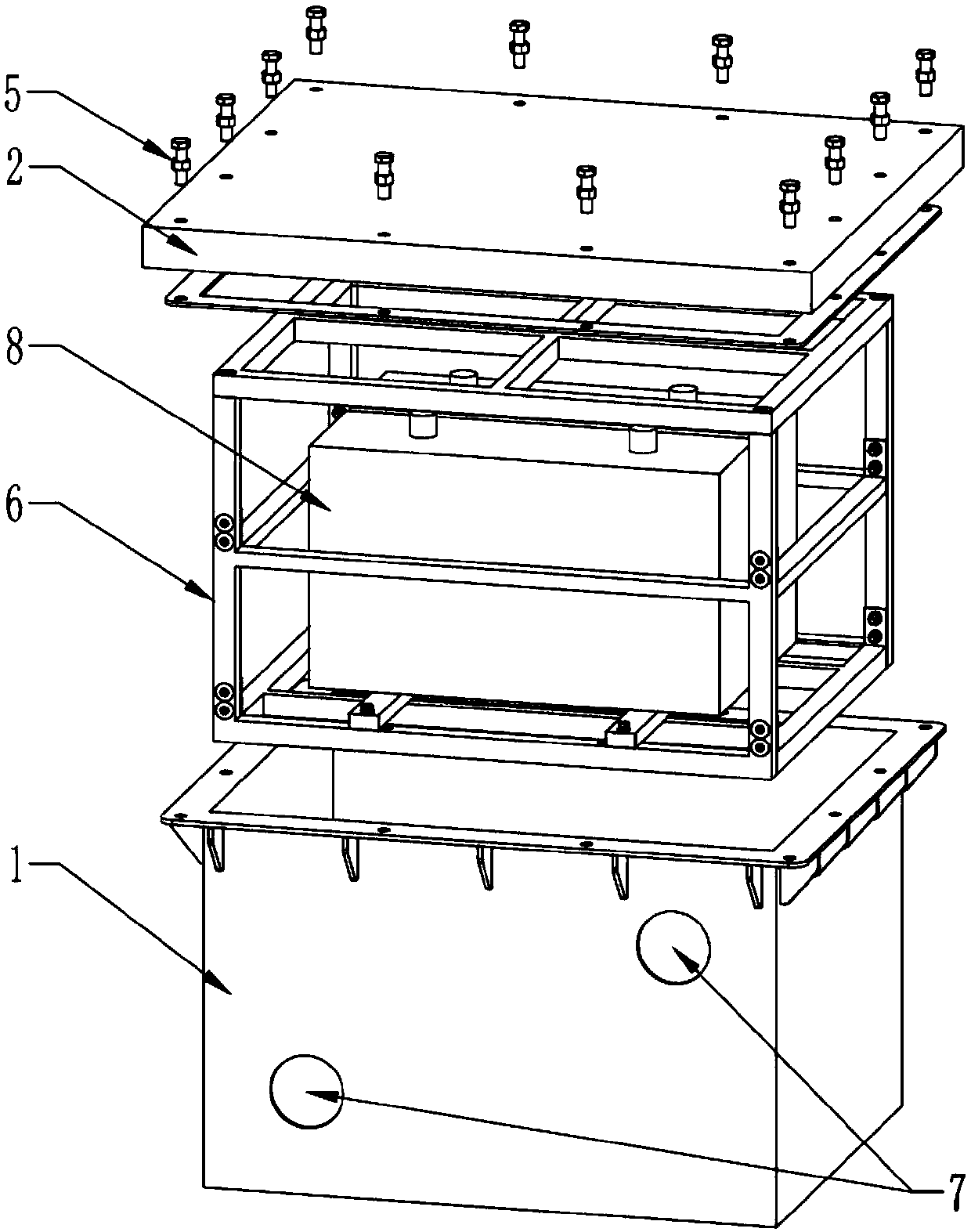

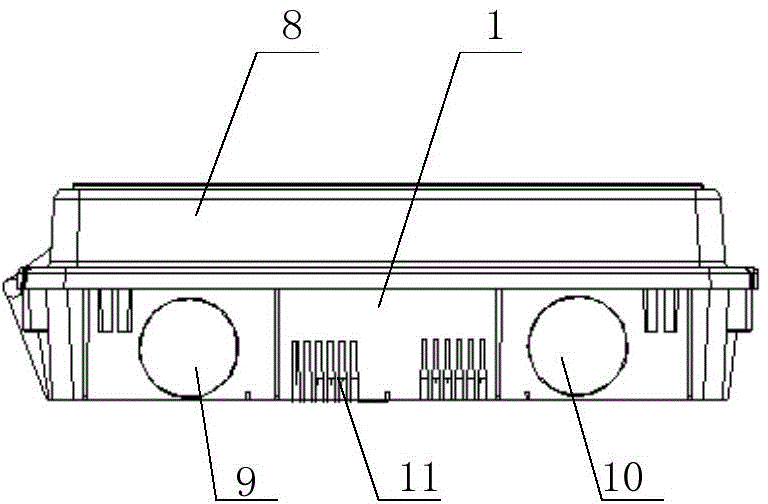

Underground system for electrical equipment

PendingCN110581236ALight in massEasy to transportBattery isolationSecondary cells servicing/maintenanceHigh humidityElectrical devices

The invention provides an underground system for electrical equipment. The underground system comprises an underground box, wherein the underground box is internally provided with a supporting frame,and the supporting frame is reasonable in structural design, convenient to disassemble and assemble and high in supporting strength. When the underground box is arranged underground, the pressure bearing strength of the box body can be improved and can reach more 2 tons or above. Due to the factor that the supporting frame is detachable, the transportation is facilitated. Compared with an underground box which is only composed of a thick and heavy metal box body and a box cover in the prior art, the underground box is light in weight, easy to transport and convenient to move. The box body andthe box cover in the underground box are connected in a sealed manner through a sealing gasket and / or a groove body structure, and the sealing grade can reach more than IP67 or above; the undergroundbox is attractive in overall appearance, has the characteristics of moisture resistance, water resistance and dust prevention, and has the functions of corrosion resistance, high humidity resistance and low temperature resistance; and the box body and the box cover are easy to process, the size is not limited by processing conditions, and the production cost is effectively reduced.

Owner:SHENZHEN COTRAN NEW MATERIAL CO LTD

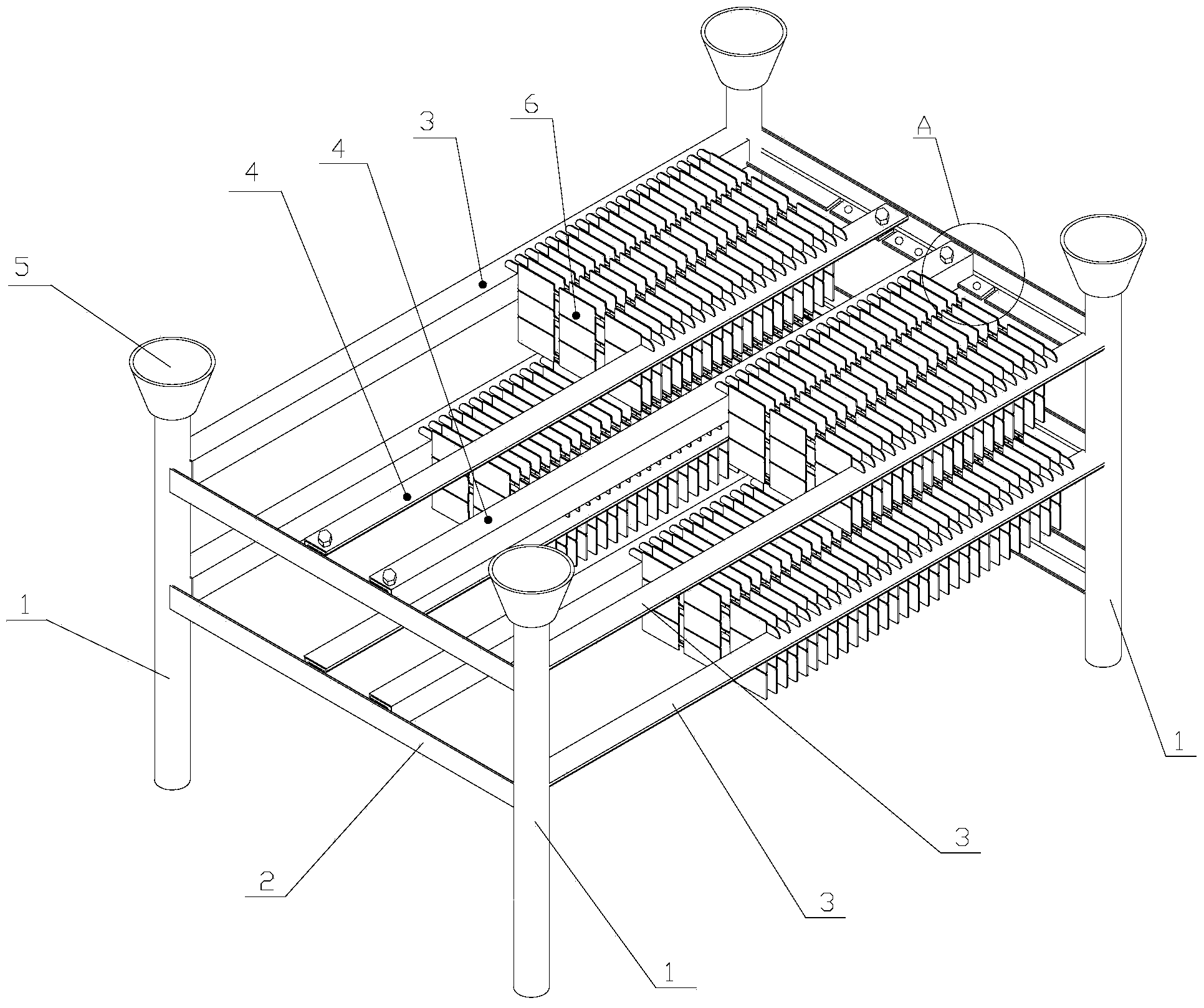

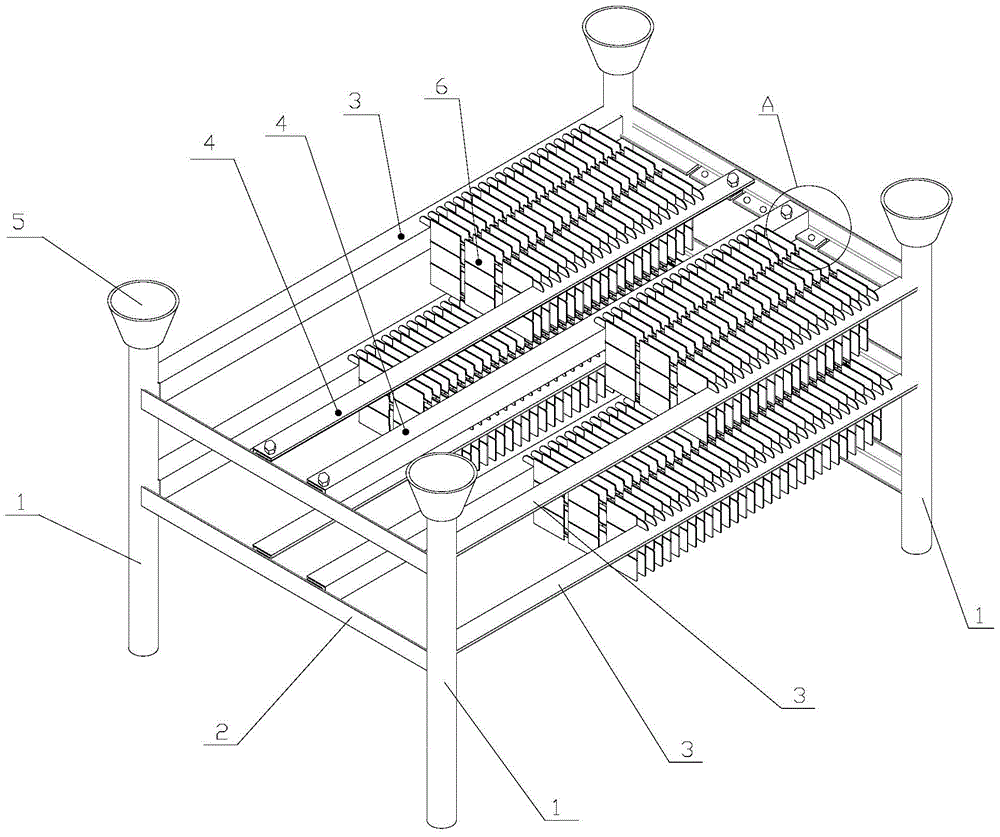

Plastic coated angle iron processing technology and storage battery pole plate solidifying frame adopting plastic coated angle iron

ActiveCN103448184ANot easy to fall offImprove the curing environmentLead-acid accumulator electrodesCoatingsEngineeringResin coating

The invention aims to discloses a plastic coated angle iron processing technology and an storage battery pole plate solidifying frame adopting the plastic coated angle iron, and solves the problems that the solidifying frame in the prior art is easy to corrode under an acid environment, and the maintenance cost is high. The invention provides a plastic coated angle iron processing technology process. The storage battery pole plate solidifying frame comprises four stand columns and at least one layer of horizontal rectangle hanging frame arranged among the four stand columns, wherein each layer of horizontal rectangle hanging frame comprises a frame body which is composed of two horizontal beams and two longitudinal beams, at least one auxiliary longitudinal beam is arranged between the two horizontal beams in each frame body, and the longitudinal beams and the auxiliary longitudinal beam are all provided with the plastic coated angle iron with resin coatings. The plastic coated angle iron processing technology and the storage battery pole plate solidifying frame provided by the invention have the advantages that resin melting solutions are soaked on the angle iron, the resin is fixedly spliced on the angle iron through cooling, the resin spliced on the angle iron is not easy to fall, the solidifying frame made of the angle iron spliced by the resin can work under an acidity condition, the angle iron can effectively prevented from being subjected to acid and rust, the solidifying environment of a pole plate is improved, the rust pollution is prevented, the frequent maintenance does not need, and the manufacturing cost is low.

Owner:CHAOWEI POWER CO LTD

Petroleum-sulfonate antirust paint

The invention discloses a petroleum-sulfonate antirust paint which comprises the following components in percentage by mass: 10-15% of petroleum-sulfonate compound antirust agent, 40-50% of acrylic resin, 20-30% of aromatic solvent, 5-10% of phenolic resin and 5-10% of assistant. The petroleum-sulfonate antirust paint does not contain water bases or toxic and harmful substances, and can effectively prevent rust.

Owner:王苏彪

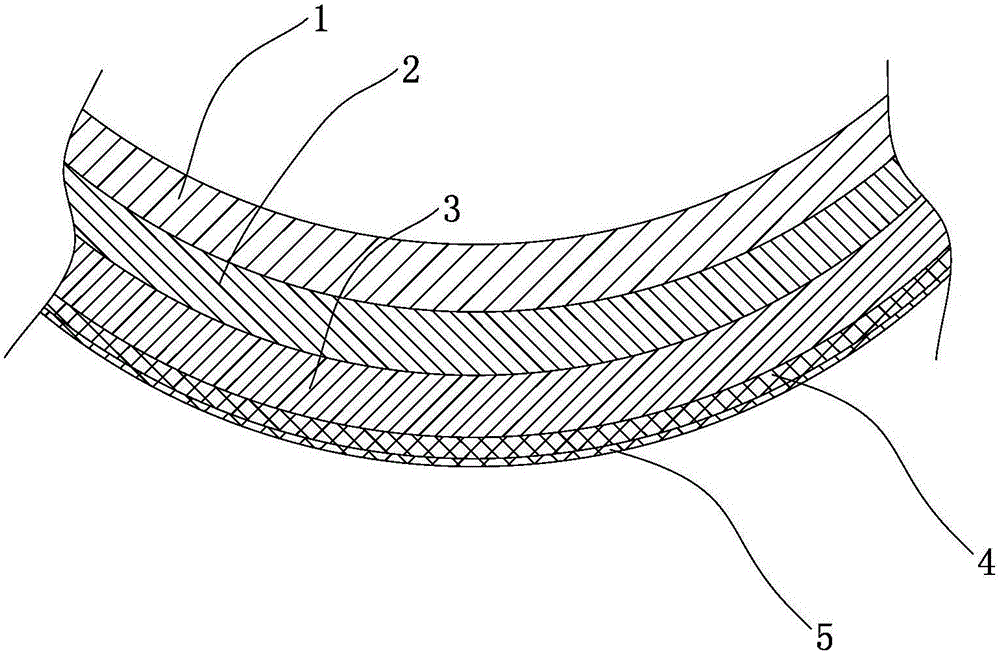

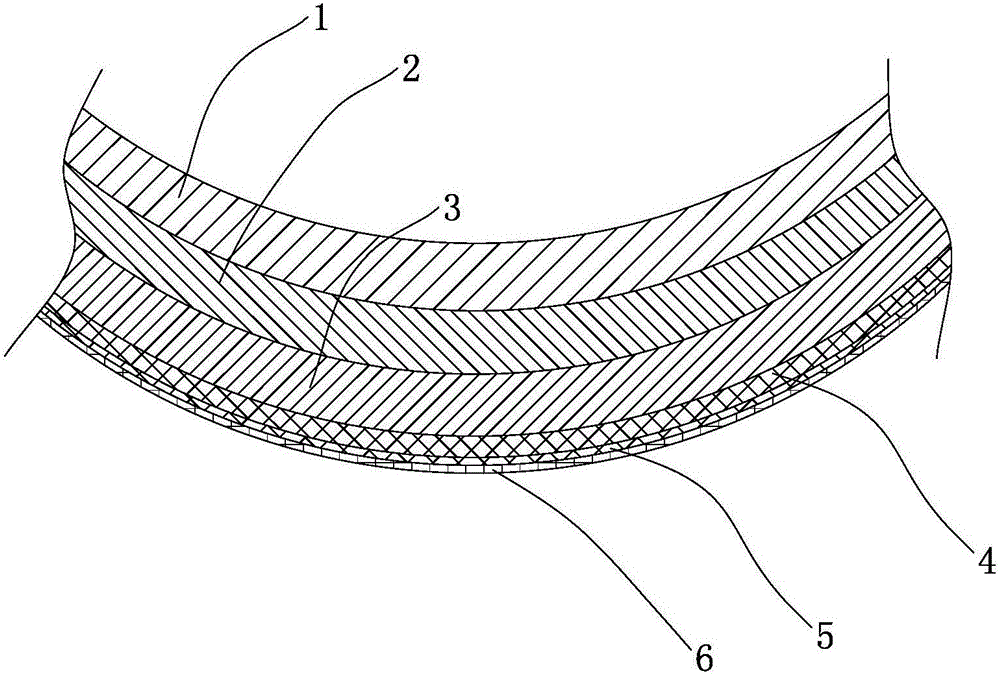

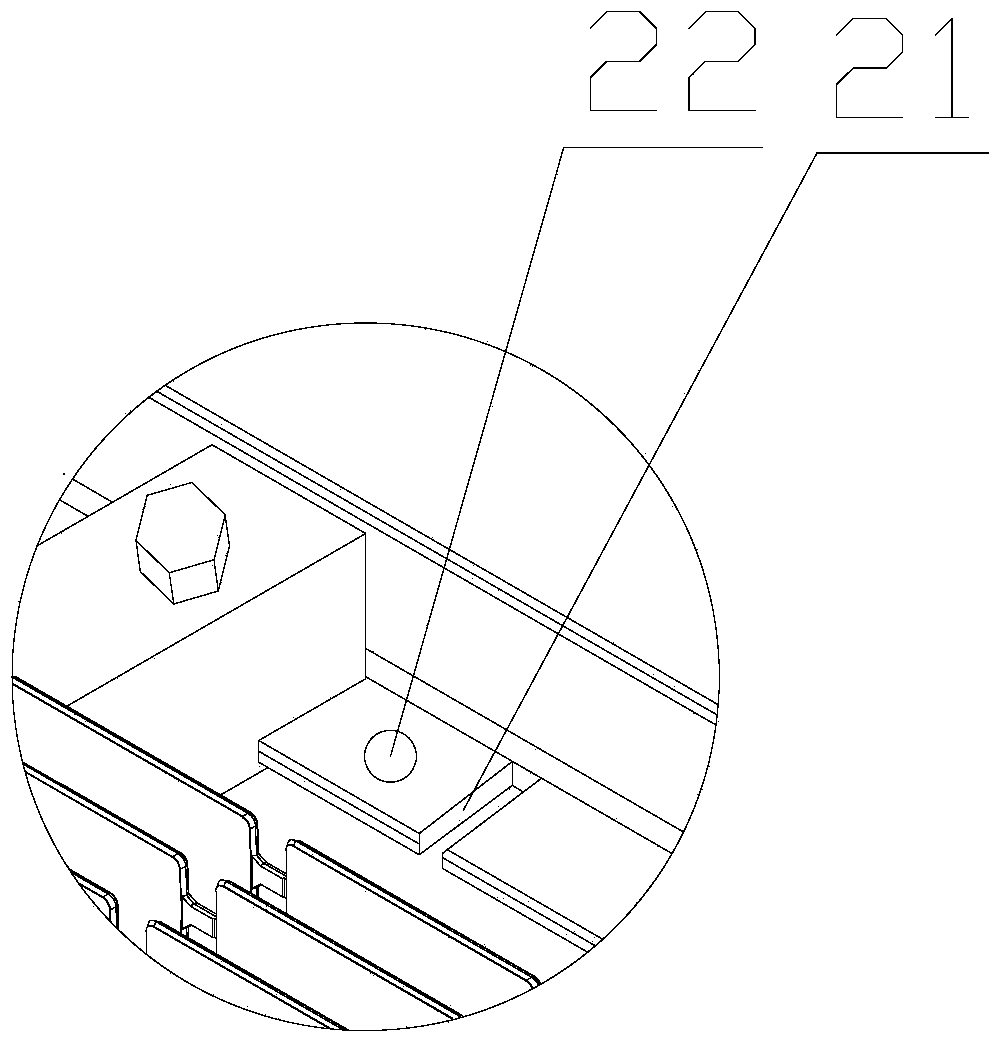

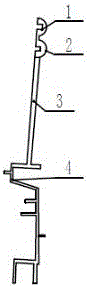

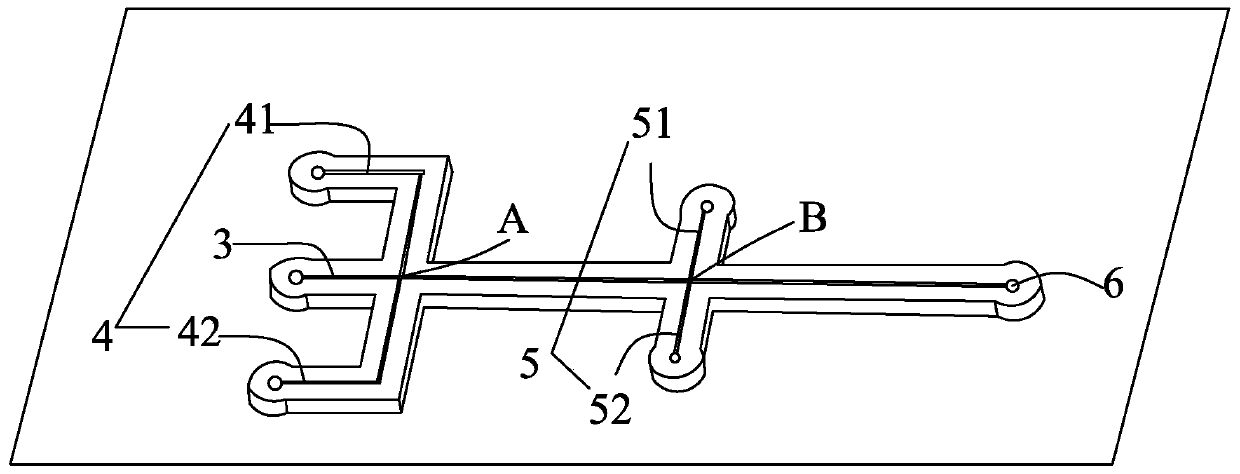

Panorama electric sunroof front beam

ActiveCN106143080AEffective anti-rustReduce manufacturing costRoofsEngineeringMechanical engineering

A panorama electric sunroof front beam is composed of a soft shaft guide pipe upper cover (1), a soft shaft guide pipe lower cover (2), a front beam body (3), a front beam cross beam (4) and interference nuts (5). The soft shaft guide pipe upper cover (1) and the soft shaft guide pipe lower cover (2) are arranged on the upper portion of the front beam body (3) in a U-shaped structure. The front beam cross beam (4) is arranged on the lower portion of the front beam body (3). The interference nuts (5) are symmetrically arranged on the left side and the right side of the front beam body (3). The panorama electric sunroof front beam is characterized in that the cross section of the soft shaft guide pipe upper cover (1) and the cross section of the soft shaft guide pipe lower cover (2) are each of a semicircular smooth boss structure, and a plurality of continuous square through holes (1-1) are formed in each boss. According to the panorama electric sunroof front beam, through the tubular structure design of the soft shaft guide pipe upper cover and the soft shaft guide pipe lower cover, the effect originally achieved through a plastic part and a metal part is omitted, the production cost is reduced, the plastic part can effectively prevent rust, and the service life of the front beam is prolonged.

Owner:丹阳金城配件有限公司

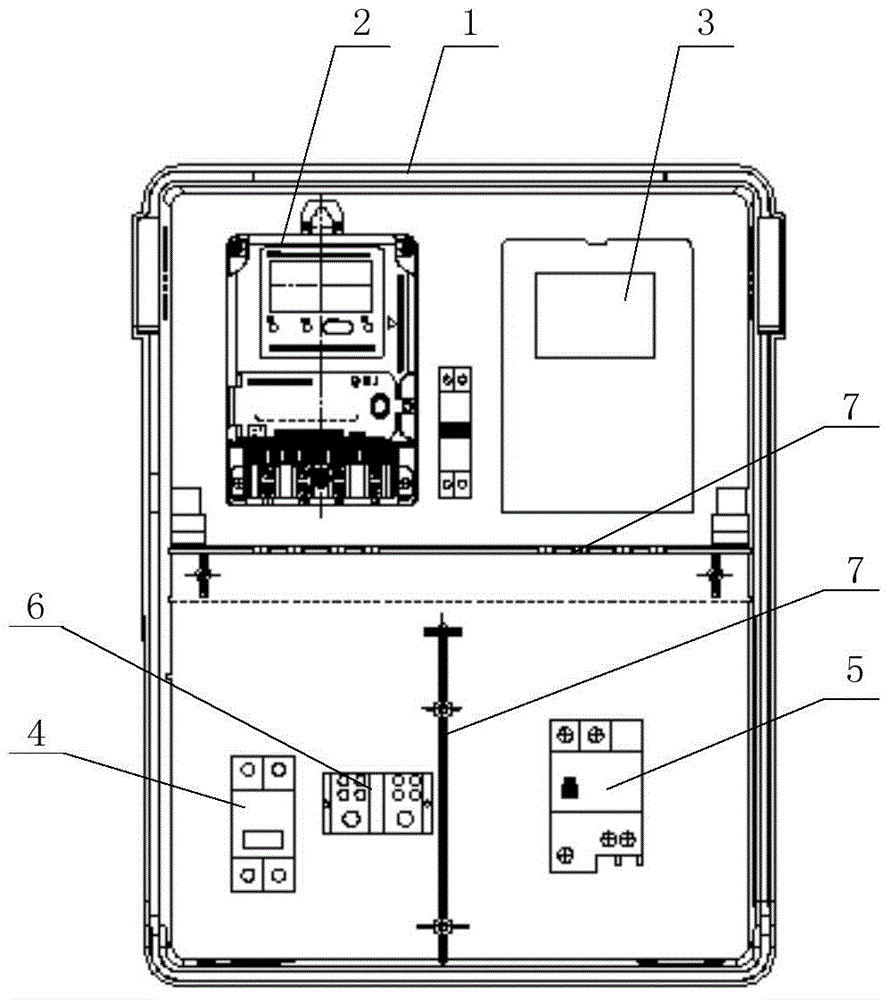

Compact electric energy meter batch meter

PendingCN106154004AHigh strengthIncrease stiffnessTime integral measurementControl roomControl theory

The invention discloses a compact electric energy meter batch meter, which comprises a box cover and a box body. The box cover is connected with the box body through a hinge. The box body comprises a metering chamber and a wiring control chamber. The metering chamber and the wiring control chamber are separated by a partition plate. The base of the box body is of a one-piece structure. The box body and the box cover are matched in the sliding manner. Water guide grooves are formed at the periphery of the box body. A triple linkage protection mechanism, based on an anti-theft bolt, a lead seal and a padlock, is formed between the box cover and the base. According to the technical scheme of the invention, the base of the box body is of the one-piece structure, thus being conveniently installed. Meanwhile, the overall strength and the overall rigidity of the box body can be improved. The triple linkage protection mechanism is formed between the box cover and the base, so that the purposes of water prevention, rust prevention, aging prevention, illegal opening prevention and electricity larceny prevention are effectively achieved. The partition plate is designed to be detachable, so that the management cost and the maintenance cost of an electric power enterprise can be reduced. Due to the arrangement of the partition plate, ventilation holes, wire incoming holes and wire outgoing holes, the internal layout of the box body is designed to be compact and attractive, and the production cost is low.

Owner:ANHUI ZHENGSHENG INTELLIGENT TECH CO LTD

Anti-corrosion oil paint

InactiveCN104927556AImprove corrosion resistanceEffective anti-rustAnti-corrosive paintsEpoxy resin coatingsDiacetone alcoholEpoxy

The invention discloses anti-corrosion oil paint. The anti-corrosion oil paint is prepared from 3-4 parts of solidification glue, 6-9 parts of methyl ethyl ketone mixture, 8-14 parts of sorbitan stearic acid, 4-7 parts of stearic acid, 3-5 parts of acidized graphite, 3-5 parts of adhesives, 4-6 parts of zinc oxide slurry, 3-8 parts of organic fluorine epoxy resin, 2-5 parts of aluminum triphosphate, 1-3 parts of polyacrylate, 5-9 parts of diacetone alcohol, 2-4 parts of triethanolamine, 2-5 parts of glucose, 4-7 parts of zeolite powder, 9-15 parts of amino resin, 3-5 parts of white spirit and 9-12 parts of rosin phenolic resin. The anti-corrosion oil paint has the advantages of excellent corrosion resistance, effectiveness in rust prevention, high adhesive force, high scratch resistance and avoidance of pungent smell.

Owner:QINGDAO ENGAO MOTION CONTROL TECH

Manufacturing method for hotly-rolled steel film coated sheet material

InactiveCN103786388AExtended service lifeEnvironmentally friendlyCovering/liningsLaminationAdhesiveUltraviolet lights

The invention relates to a manufacturing method for a building sheet material which has corrosion-resisting and weather-resisting performances, can prevent dew from dripping off and has a certain heat-preservation performance, and particularly relates to a manufacturing method for a hotly-rolled steel film coated sheet material. The manufacturing method comprises the following steps: selecting materials, pre-treating a sheet surface, carrying out drying treatment, coating an adhesive, coating a film, carrying out a drying procedure, hotly pressing, checking and storing. According to the method, an obtained product has a very good fireproof performance; as being detected, the hotly-rolled steel film coated sheet material obtains the national building material fireproof B-1-grade authentication, is completely environmentally-friendly and has no pollution; the hotly-rolled steel film coated sheet material also obtains the environment-friendly authentication, has the long service life, is environmentally-friendly, has the fireproof, anti-dewing and corrosion-resisting effects, and has the effects of sound absorption, light absorption, heat preservation, high transparency, high glossiness, low haze, excellent ultraviolet light barrier property, laser anti-counterfeiting property and bright decoration effect.

Owner:WUXI XINDAZHONG STEEL SHEET

Sliding rail for automobile sliding door

InactiveCN106320876AReduce coefficient of frictionReduce wear rateMolten spray coatingVehicle locksGraphene coatingEngineering

The invention discloses a sliding rail for an automobile sliding door. The surface of the sliding rail is provided with a plasma spraying Cr3C2-NiCr-graphene coating with a thickness of 20-30 [mu]m. The coating reduces friction coefficient and wear rate simultaneously, and the sliding door has a low friction coefficient and excellent wear resistance. Under each load, the wear rate is reduced by 50% or above compared with a base body.

Owner:WUXI MINGSHENG STRONG BLOWER

One motor, one transmission device, two tracks, two sets of curtains, single and two-way opening and closing electric curtain machine

The invention relates to an electric curtain machine. The electric curtain machine comprises a motor, a transmission device and a double-rail aluminum alloy machine box with the -shaped cross section and is controlled manually with one button, capable of performing limiting automatically, provided with a built-in minitype clutch device and capable of driving one curtain (a window shade or a gauze shade) or simultaneously driving two curtains (window shades or gauze shades). The electric curtain machine overcomes the defects existing in the situation that a motor and a transmission device cannot simultaneously drive double rails and two curtains. A minitype alternating current gear motor, a clutch driving device with a major functional piece arranged in a hollow wheel hub of a driving wheel, a driven wheel device with the tension capable of being adjusted, a nickel-plated chain, nylon travel idler wheels, nylon idler wheels, nylon pulleys, a travel limiting switch and stainless hooks are integrated inside and outside the double-rail aluminum alloy machine box. According to the electric curtain machine capable of being operated by hand after power failure, the chain is made to make horizontal reciprocating motor in the machine box through frontward and backward rotation of the motor so that the one or two curtains below the double rails can be driven to be opened or closed and stopped in a single direction or in double directions and can make the two curtains be opened or closed simultaneously.

Owner:王晓东

Production method for electrogalvanizing laminated boards

InactiveCN103790308AExtended service lifeEnvironmentally friendlyCovering/liningsLamination ancillary operationsFireproofingUltraviolet lights

The invention relates to a production method for anti-corrosive, weather-proof and dew-dripping preventive building boards with a certain heat insulation performance, in particular to a production method for electrogalvanizing laminated boards. The production method includes the steps of material selecting, board surface pre-processing, drying treatment, adhesive coating, laminating, drying, hot pressing, inspecting and storing. Products produced by the production method have good fireproofing performance, pass the national building material fireproofing grade certification B-1 according to tests, is completely environment friendly and pollution-free, pass the environmental protection certification, and have the advantages of long service life, environment protection, fireproofing, condensation and corrosion resistance, sound and light absorption, heat insulation, high transparency, high glossiness, low haze, excellent ultraviolet-light isolation property, laser anti-fake property and bright decorative effect.

Owner:WUXI XINDAZHONG STEEL SHEET

Rust-proof crawler chassis

InactiveCN107813881AEffective anti-rustExtended service lifePretreated surfacesAnti-corrosive paintsEpoxyAbrasive blasting

The invention provides a rust-proof crawler chassis. The crawler chassis is coated with a protective layer. A coating method comprises the following steps of 1, conducting sandblasting treatment on the outer surface of the crawler chassis; 2, weighing raw materials, wherein the raw materials include, by weight, 15-28 parts of epoxy resin, 3-5.6 parts of isocyanate, 0.5-3.2 parts of dimethylbenzene, 2-6 parts of silicon dioxide, 8-15 parts of ethanol, 0.03-0.08 part of defoaming agent and 0.8-1.2 parts of photoinitiator; 3, evenly stirring the raw materials at 40-55 DEG C and then coating the outer surface of the crawler chassis with the mixed raw materials, and conducting drying. Rust is effectively prevented, and the service life is prolonged.

Owner:ZHENJIANG SHEN WARD MACHINERY CO LTD

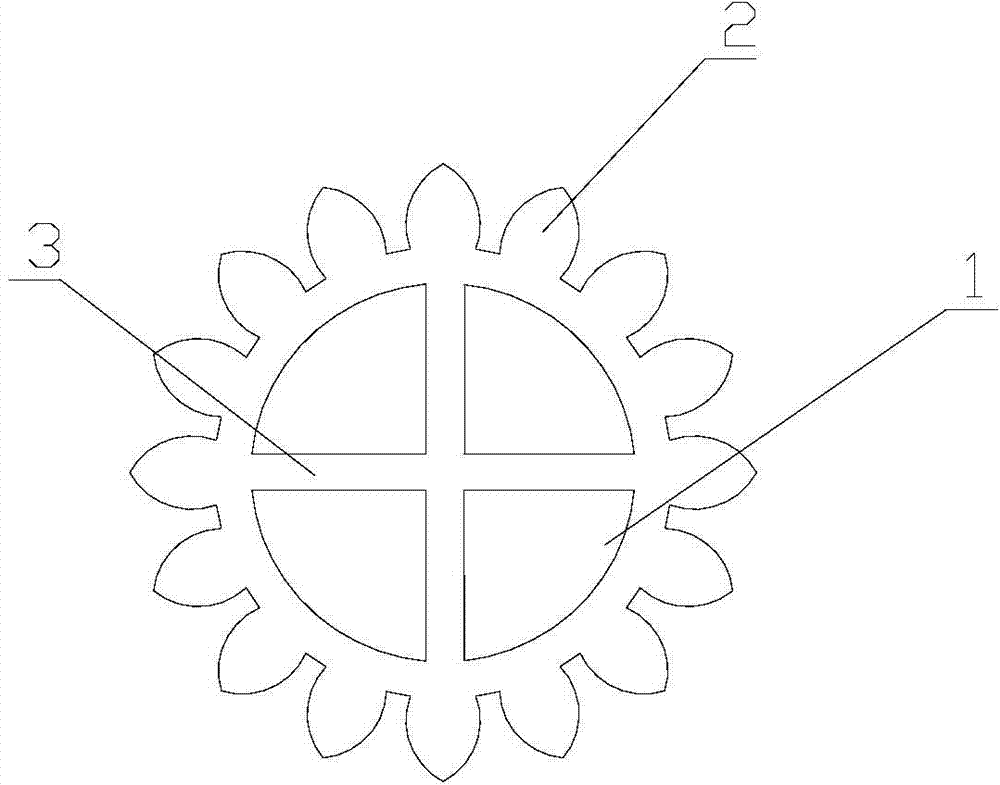

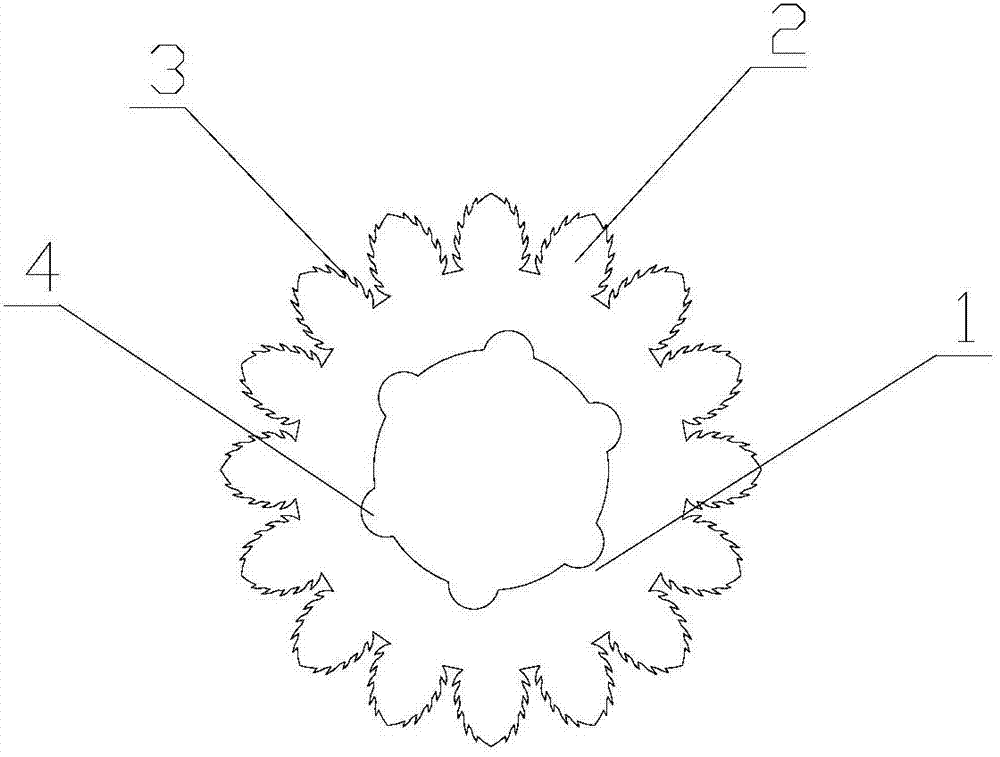

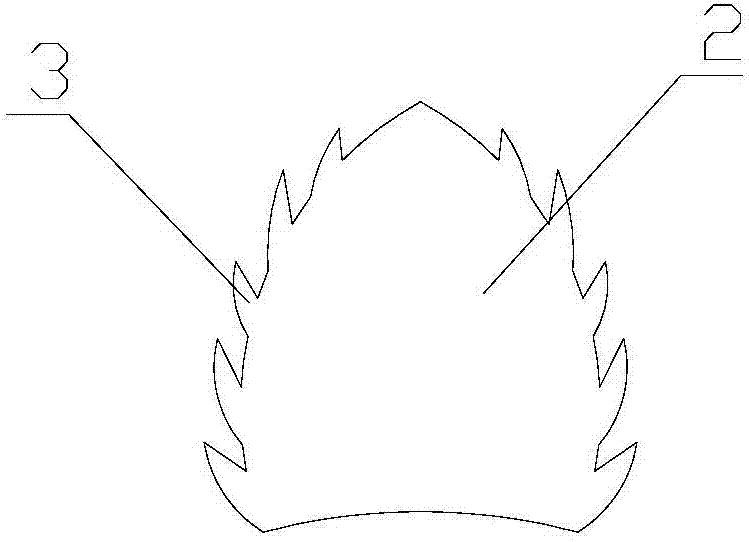

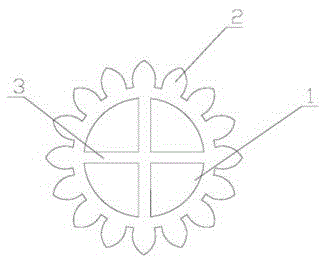

Mechanical gear wheel

InactiveCN104763794AReduce wearSolution to short lifePortable liftingGearing elementsGear wheelEngineering

The invention relates to the technical field of mechanical transmission components, and specifically relates to a mechanical gear wheel comprising a gear wheel body, wherein the center of the gear wheel body is provided with a shaft hole, the outer edge of the gear wheel body is provided with a gear ring consisted of a plurality of leaf-shaped sawteeth, a cross type connecting frame is arranged in the middle of the gear ring to divide the gearing into four fan-shaped openings that are symmetric in the upper, lower, left and right directions. With the abrasion being reduced, the mechanical gear wheel is long in service life, more flexible in transmission, effective in rust protection, convenient to locate, and good in using effect.

Owner:方乐

Anti-rust track

InactiveCN107722781AEffective anti-rustExtended service lifePretreated surfacesAnti-corrosive paintsEpoxyEngineering

The invention provides an anti-rust track, which comprises a track chassis and a rubber track, wherein the rubber track covers the outer portion of the track chassis, and the track chassis is coated to form a protection layer. The coating method comprises: (1) carrying out sand blasting treatment on the outer surface of the track chassis; (2) weighing raw materials, wherein the raw materials comprise an epoxy resin, isocyanate, xylene, silica, ethanol, a defoamer and a photoinitiator; and (3) uniformly stirring the raw materials at a temperature of 40-55 DEG C, coating the outer surface of thetrack chassis with the obtained mixture, and drying, wherein the components of the rubber track comprise isoprene rubber, chloroprene rubber, a reinforcing agent, a vulcanizing agent, paraffin, ethanol and perglutaric acid. According to the present invention, the effective anti-rust effect is provided, and the service life is prolonged.

Owner:ZHENJIANG SHEN WARD MACHINERY CO LTD

A positioning fixture and clamping method for titanium alloy ring castings

ActiveCN109129186BAchieve circumferential positioningAchieving a centering effectGrinding work supportsTitanium alloyMechanical engineering

The invention provides a positioning clamp used for a titanium alloy ring-shaped casting and a clamping method. The positioning clamp mainly comprises a rotating worktable, two floating V-shaped blockassemblies, three pin assemblies and one three-claw chuck. The titanium alloy ring-shaped casting is positioned through a clamp and is clamped to the surface of the rotating worktable. Three positioning pins are matched with the end face of the titanium alloy ring-shaped casting so as to limit the linear freedom degree of the titanium alloy ring-shaped casting in the height direction and two rotation freedom degrees. V-shaped blocks are matched with an elliptical structure on the titanium alloy ring-shaped casting to limit the circumferential rotation freedom degree of the titanium alloy ring-shaped casting. The three-claw chuck is matched with a circular inner hole of the titanium alloy ring-shaped casting to limit the linear freedom degree of the titanium alloy ring-shaped casting on the plane, and clamping is achieved. By means of the clamp, complete positioning of the titanium alloy ring-shaped casting is achieved, the clamp is suitable for front-face and back-face clamping of thetitanium alloy ring-shaped casting, and a servo motor arranged in a rotating worktable can be controlled to make the rotating worktable drive the clamp and the titanium alloy ring-shaped casting to rotate to the designated angle after clamping is completed.

Owner:WUHAN UNIV OF TECH

A kind of magnetic particle, preparation method and application thereof

ActiveCN106938861BAchieve separationSimple internal structureOther chemical processesSpecific water treatment objectivesMethacrylateActive agent

The invention discloses a magnetic particle. The magnetic particle comprises a magnetic core and a porous shell coating the external of the core; the core is made of hydrocarbon oil, nanometer magnetic powder and a surfactant; and the shell is made of a photoinitiator, polyethylene glycol dimethacrylate, a pore forming agent and the surfactant. The invention also discloses a preparation method and an application of the magnetic particle. The magnetic particle is placed in sewage to separate oily pollutants from the sewage, and the filtered water is reused in industrial production.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

High-stability concrete release agent

InactiveCN113862071ASolve pollutionEfficient and stableLubricant compositionOil and greaseEnvironmental engineering

The invention discloses a high-stability concrete release agent which is prepared from the following components in percentage by weight: 30-40% of an oil raw material, 2-5% of an emulsifier, 1-3% of an auxiliary agent, 0.2-1% of a stabilizer, 0.1-0.3% of a high-molecular polymer and the balance of water. Vegetable oil or waste grease is adopted as base oil, the waste grease is a mixture of vegetable oil and animal oil, both the vegetable oil and the waste grease are renewable substances, and in addition, the problem of environmental pollution can be further solved by adopting the waste grease. The emulsifier added in the concrete release agent has efficient stability, the added triethanolamine can effectively prevent rust, and the added high-molecular polymer can improve the release effect. The concrete release agent has the advantages of being environmentally friendly, high in stability and capable of being repeatedly used after being applied once. Moreover, the surface strength of concrete can be improved, the weather resistance of concrete is effectively improved, and the service life of a concrete member is prolonged.

Owner:湖南加美乐素新材料股份有限公司

Ionized current superfine foam generating device and ionized current superfine foam generating method using device

InactiveCN101643257BEasy to eluteEasy to removeWater/sewage treatment by flotationMolecular clusterFiltration

The invention relates to an efficient ionized current superfine foam generating device and an ionized current superfine foam generating method using the device, which can purify the water quality of polluted water. The system and the method are characterized in that inflow water in a molecular cluster state is naturally absorbed and then stirred, and the active motion of water molecules is activated by radiation wavelengths which are emitted from a far infrared lamp and have water molecule resonance absorption wavelengths; by means of the self-heating and resonance phenomenon produced by high-speed rotation of the water molecules, the electrolysis operation is carried out without an electrode, and then superfine foams sheared when flowing through a micro-pore filtration core collide with the electrolyzed water; the foams are effectively dissolved and stored by using a flow path and pressure change caused by sectional area change of the flow path and generate ion pressurized water; theion pressurized water is prayed to the water in an atmospheric pressure state to generate ionized current superfine foams; and then the superfine foams and polluted substances float up the water together so as to effectively purify the polluted water.

Owner:郑浩荣

An oil-drying and drying device for mechanical parts

ActiveCN109876995BEffective anti-rustImprove recycling rateLiquid surface applicatorsCoatingsHydraulic cylinderThermodynamics

Owner:刘忠义

Processing technology of plastic-coated angle steel and battery plate curing frame using the plastic-coated angle steel

ActiveCN103448184BNot easy to fall offImprove the curing environmentLead-acid accumulator electrodesCoatingsEngineeringResin coating

The invention aims to discloses a plastic coated angle iron processing technology and an storage battery pole plate solidifying frame adopting the plastic coated angle iron, and solves the problems that the solidifying frame in the prior art is easy to corrode under an acid environment, and the maintenance cost is high. The invention provides a plastic coated angle iron processing technology process. The storage battery pole plate solidifying frame comprises four stand columns and at least one layer of horizontal rectangle hanging frame arranged among the four stand columns, wherein each layer of horizontal rectangle hanging frame comprises a frame body which is composed of two horizontal beams and two longitudinal beams, at least one auxiliary longitudinal beam is arranged between the two horizontal beams in each frame body, and the longitudinal beams and the auxiliary longitudinal beam are all provided with the plastic coated angle iron with resin coatings. The plastic coated angle iron processing technology and the storage battery pole plate solidifying frame provided by the invention have the advantages that resin melting solutions are soaked on the angle iron, the resin is fixedly spliced on the angle iron through cooling, the resin spliced on the angle iron is not easy to fall, the solidifying frame made of the angle iron spliced by the resin can work under an acidity condition, the angle iron can effectively prevented from being subjected to acid and rust, the solidifying environment of a pole plate is improved, the rust pollution is prevented, the frequent maintenance does not need, and the manufacturing cost is low.

Owner:CHAOWEI POWER CO LTD

Engine gear

InactiveCN104747684AImprove rust resistanceGuaranteed lubrication effectPortable liftingGearing elementsRustMechanical transmission

The invention relates to the technical field of mechanical transmission parts, in particular to an engine gear which comprises a gear body of a hollow structure. A gear ring formed by a plurality of leaf-shaped sawteeth is arranged at the outer edge of the gear body. Two rows of small sawteeth are symmetrically arranged at the edges of the leaf-shaped sawteeth. A plurality of arc concave openings which are distributed evenly are formed in the inner circle of the gear ring inwards. According to the engine gear, abrasion can be lowered, service life is long, transmission is flexible, effective rust protection can be achieved, and using effect is good.

Owner:方乐

Mechanical gear

InactiveCN105626829AImprove rust resistanceGuaranteed lubrication effectPortable liftingGear lubrication/coolingGear wheelEngineering

The invention relates to the technical field of mechanical transmission components, and in particular relates to a mechanical gear which comprises a gear body, wherein the center of the gear body is provided with a shaft hole; the outer edge of the gear body is provided with a gear ring consisting of a singular number of leaf-shaped saw teeth; and the middle of the gear ring is divided into four sector-shaped open pores which are symmetrical in up-and-down direction and left-and-right direction by virtue of a cross-shaped connecting rack. The mechanical gear is capable of reducing corrosion, long in service life, flexible in transmission, capable of effectively preventing rust, convenient in locating and good in use effect.

Owner:马怡鑫

Sliding rail for sliding doors of automobiles

The invention discloses a sliding rail for sliding doors of automobiles. A graphene nickel-based composite coating with a thickness of 20-30 microns is arranged on the surface of the sliding rail. Through the composite coating, the friction coefficient and wear rate are reduced at the same time, and the composite coating has a relatively low friction coefficient and has abrasive resistance more excellent than that of Cr coatings. Under each load, the wear rate is reduced by more than 50% than a matrix.

Owner:WUXI MINGSHENG STRONG BLOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com