Iron composite cooker and surface processing method for same

A processing method and technology for cooking utensils, which are applied in metal material coating technology, special materials for cooking utensils, coatings, etc., can solve the problems of iron supplementation, peeling off, poor heat conduction, etc., to improve anti-pollution ability, improve Anti-rust performance, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

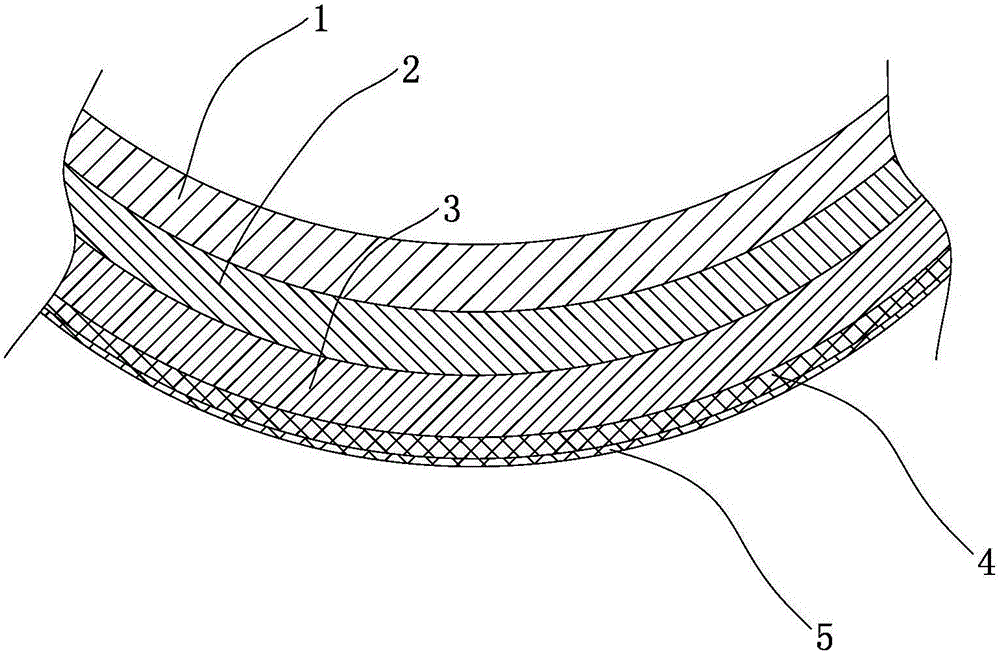

[0026] The cooking utensils made of iron-aluminum-iron three-layer composite material are first degreased and polished mechanically, and then placed in a plasma oxynitridation furnace with multiple auxiliary heat sources. The surface processing methods are as follows:

[0027] a) First raise the temperature of the workpiece surface to 350°C at normal temperature, and stay for 10-30 minutes; then start adding gas when the temperature rises to 400°C and continue to heat up. Nitriding treatment is carried out in an atmosphere of 4-9:1, the time is 5-6 hours, and a nitrided layer with N-C-Fe compound is formed on the surface of the substrate, and the thickness of the nitrided layer is controlled at 10-50 microns; b) further Control the temperature at 430-490°C, and carry out nitrocarburizing in an atmosphere with a volume ratio of nitrogen:hydrogen:carbon monoxide:oxygen of 4-9:1:0.1-0.3:0.05-0.1 for 1-4 hours , form an oxynitride layer with N-C-O-Fe compound on the surface of the...

Embodiment 2

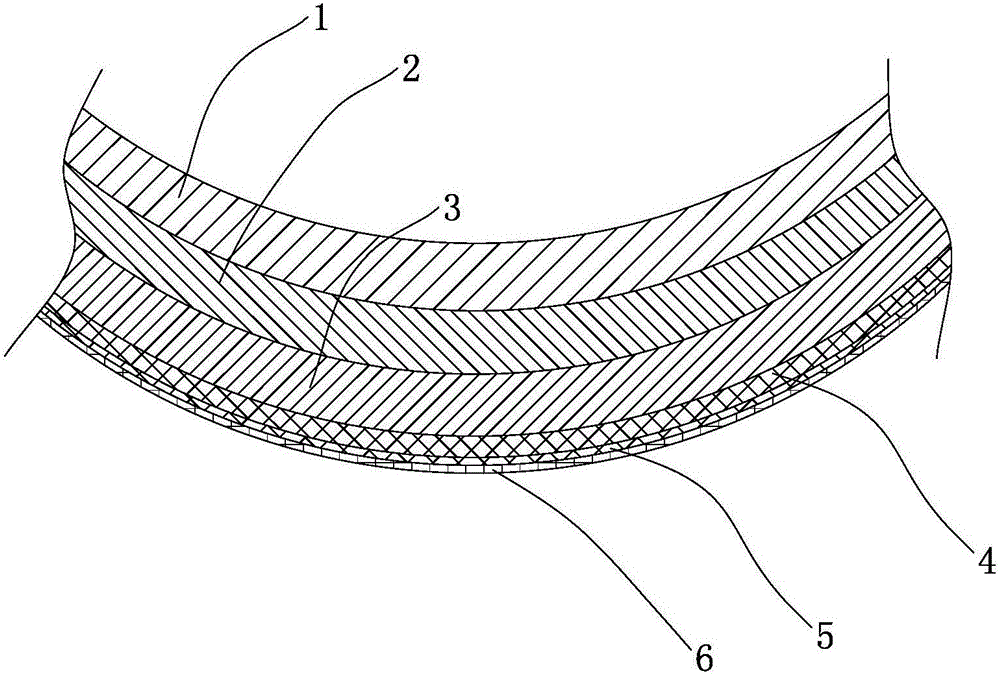

[0034] For cookware made of iron-aluminum-iron three-layer composite material, the inner iron layer is used to wrap the cookware base first, so that the surface of the product is all iron materials, and the surface is degreased and polished mechanically, and then It is placed in a plasma oxynitridation furnace with multiple auxiliary heat sources, and its surface is processed as follows:

[0035]First raise the surface temperature of the workpiece to 350°C at room temperature and stay for 10-30 minutes; then start adding gas when the temperature rises to 400°C and continue to heat up. In the temperature range of 450-480°C, the volume ratio of nitrogen:hydrogen is Nitriding treatment is carried out in an atmosphere of -9:1, and the time is 5-6 hours to form a nitrided layer with N-C-Fe compound on the surface of the substrate, and the thickness of the nitrided layer is controlled at 10-50 microns; b) further increase the temperature Controlled at 430-490°C, carry out nitrocarbu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com