A kind of magnetic particle, preparation method and application thereof

A magnetic particle and magnetic technology, applied in chemical instruments and methods, other chemical processes, special treatment targets, etc., to achieve the effect of recycling and reducing the chance of rusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

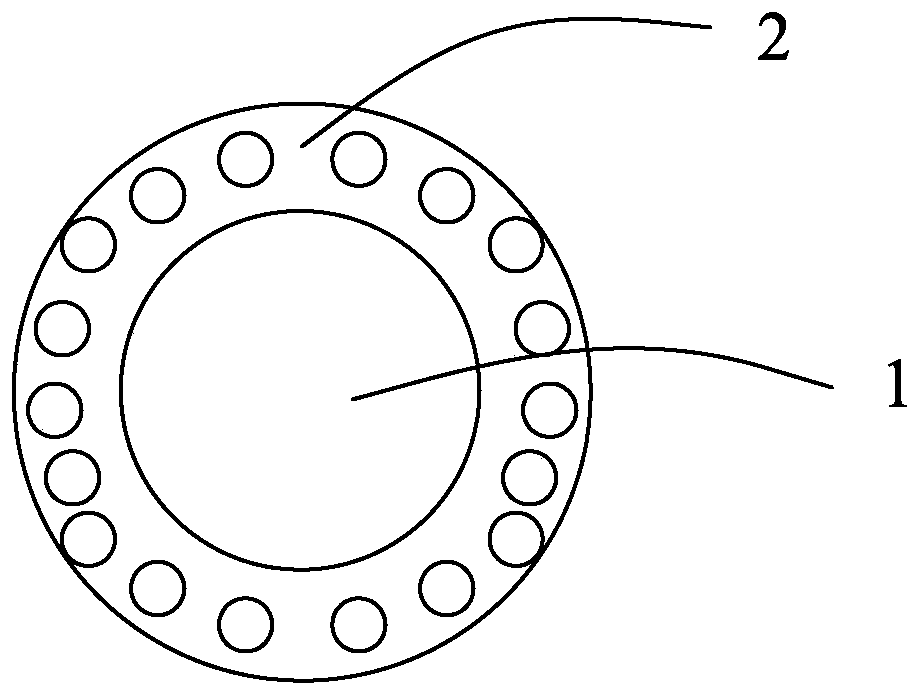

[0035] A magnetic particle, comprising a magnetic core 1 and a porous shell 2 coated on the outside of the core; the core 1 is composed of trimethylbenzene, Fe 3 o 4 and SPAN80; the shell 2 is prepared from DAROCUR 1173, polyethylene glycol dimethacrylate, dimethyl phthalate and SPAN80.

[0036] A method for preparing magnetic particles, comprising the steps of:

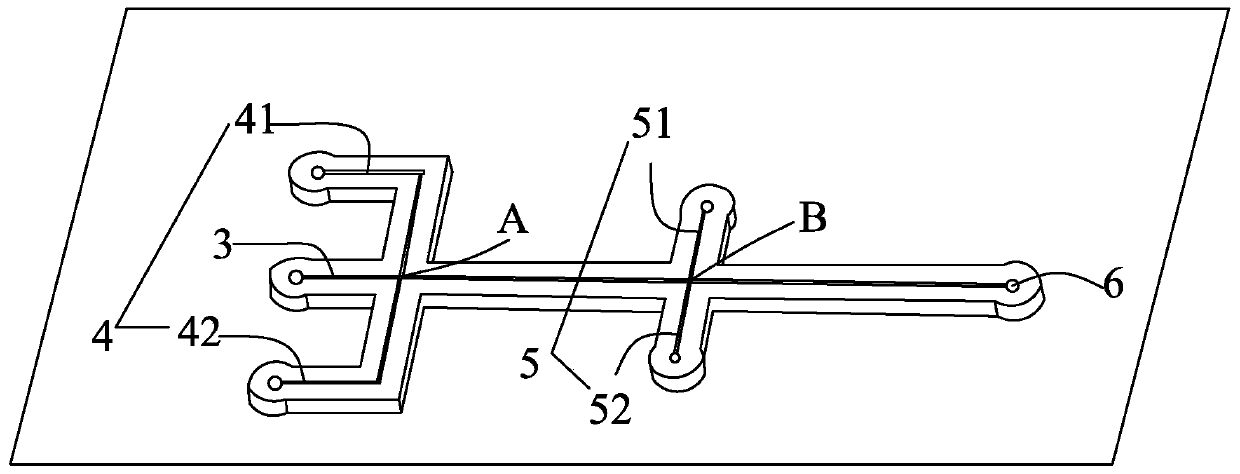

[0037] 1) By soft photolithography, prepare a microfluidic chip in which channels with a two-stage copolymerization flow structure are connected in series; the microfluidic chip includes an inner channel 3, a middle channel 4, an outer channel 5, and an outflow channel 6; The fluidic chip material is an acrylic plate, the chip is 10cm long, the microchannel is 500 μm wide, and 500 μm high; the middle channel 4 is located on both sides of the inner channel 3, including the first middle channel 41 and the second middle channel 42; the outer channel is located at Between the inner channel and the outflow channel, the ...

Embodiment 2

[0046] A magnetic particle, comprising a magnetic core 1 and a porous shell 2 coated on the outside of the core; the core 1 is composed of trimethylbenzene, Fe 2 o 3 and octyltrimethylammonium bromide; the shell 2 is prepared from DAROCUR 1173, polyethylene glycol dimethacrylate, dimethyl phthalate and block polyether F108 (2%wt) become.

[0047] A method for preparing magnetic particles, comprising the steps of:

[0048] 1) By soft photolithography, prepare a microfluidic chip in which channels with a two-stage copolymerization flow structure are connected in series; the microfluidic chip includes an inner channel 3, a middle channel 4, an outer channel 5, and an outflow channel 6; The fluidic chip material is an acrylic plate, the chip is 10cm long, the microchannel is 500 μm wide, and 500 μm high; the middle channel 4 is located on both sides of the inner channel 3, including the first middle channel 41 and the second middle channel 42; the outer channel is located at Be...

Embodiment 3

[0054] A magnetic particle, comprising a magnetic core 1 and a porous shell 2 coated on the outside of the core; the core 1 is prepared from trimethylbenzene, FeO and octyltrimethylammonium bromide; the shell 2 Prepared from DAROCUR 1173, polyethylene glycol dimethacrylate, dimethyl phthalate and SPAN80.

[0055] A method for preparing magnetic particles, comprising the steps of:

[0056] 1) By soft photolithography, prepare a microfluidic chip in which channels with a two-stage copolymerization flow structure are connected in series; the microfluidic chip includes an inner channel 3, a middle channel 4, an outer channel 5, and an outflow channel 6; The fluidic chip material is an acrylic plate, the chip is 10cm long, the microchannel is 500 μm wide, and 500 μm high; the middle channel 4 is located on both sides of the inner channel 3, including the first middle channel 41 and the second middle channel 42; the outer channel is located at Between the inner channel and the outf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com