Underground system for electrical equipment

A kind of technology of buried box and control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0099] [Preparation method of polypropylene composite material]

[0100] The present invention also provides the preparation method of above-mentioned composite material, it comprises the steps:

[0101] (1) proportioning polypropylene, high-density polyethylene, silicon micropowder, and EPDM rubber in proportion, stirring and blending in a mixer or mixer;

[0102] (2) Add the above-mentioned compound to the extruder to obtain a flake melt.

[0103] In a preferred embodiment of the present invention, preferably said step (1) is carried out in a high-speed kneader, the stirring and blending time is less than 10 minutes, such as 3-5 minutes; the speed of the high-speed kneader is controlled at 300-500r / min;

[0104] In a preferred embodiment of the present invention, the processing temperatures of the extruder in the preferred step (2) are respectively 130-140°C, 170-180°C, 190-200°C, 200-205°C, 210- 220°C, 220-230°C.

[0105] In a preferred embodiment of the present invent...

Embodiment 1

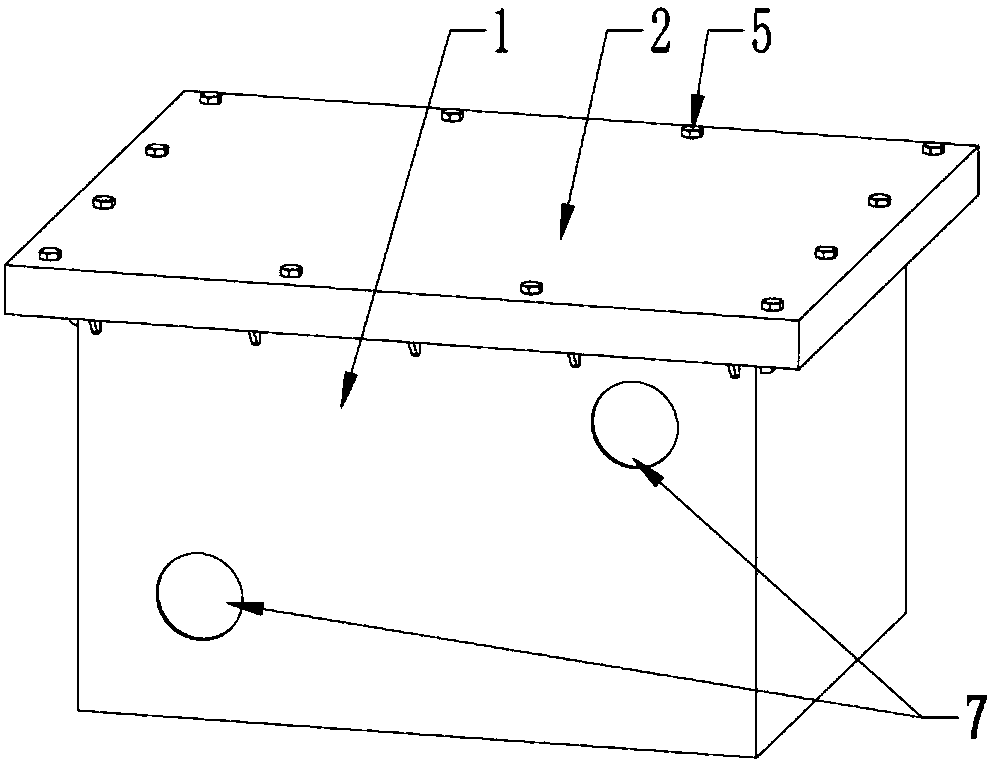

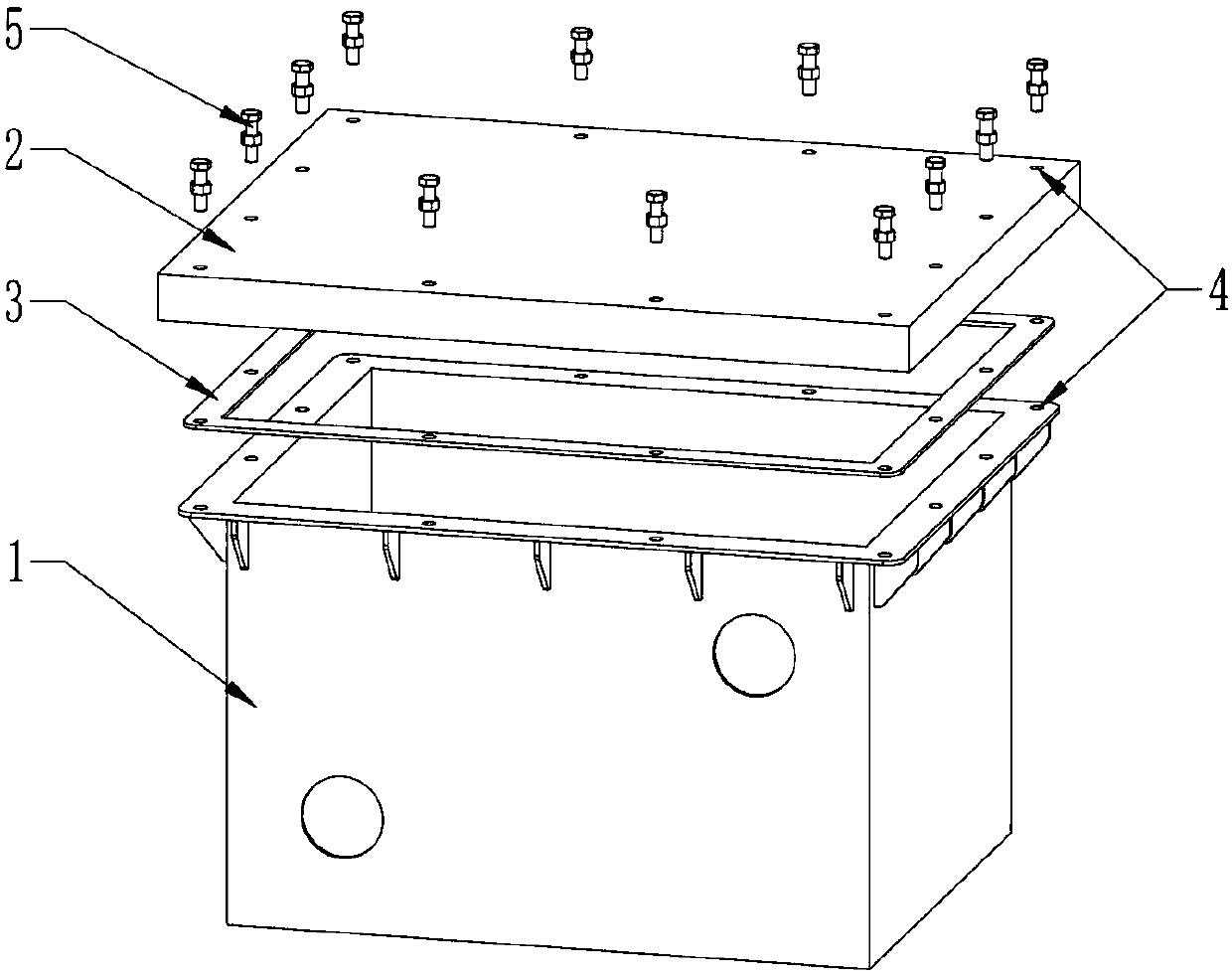

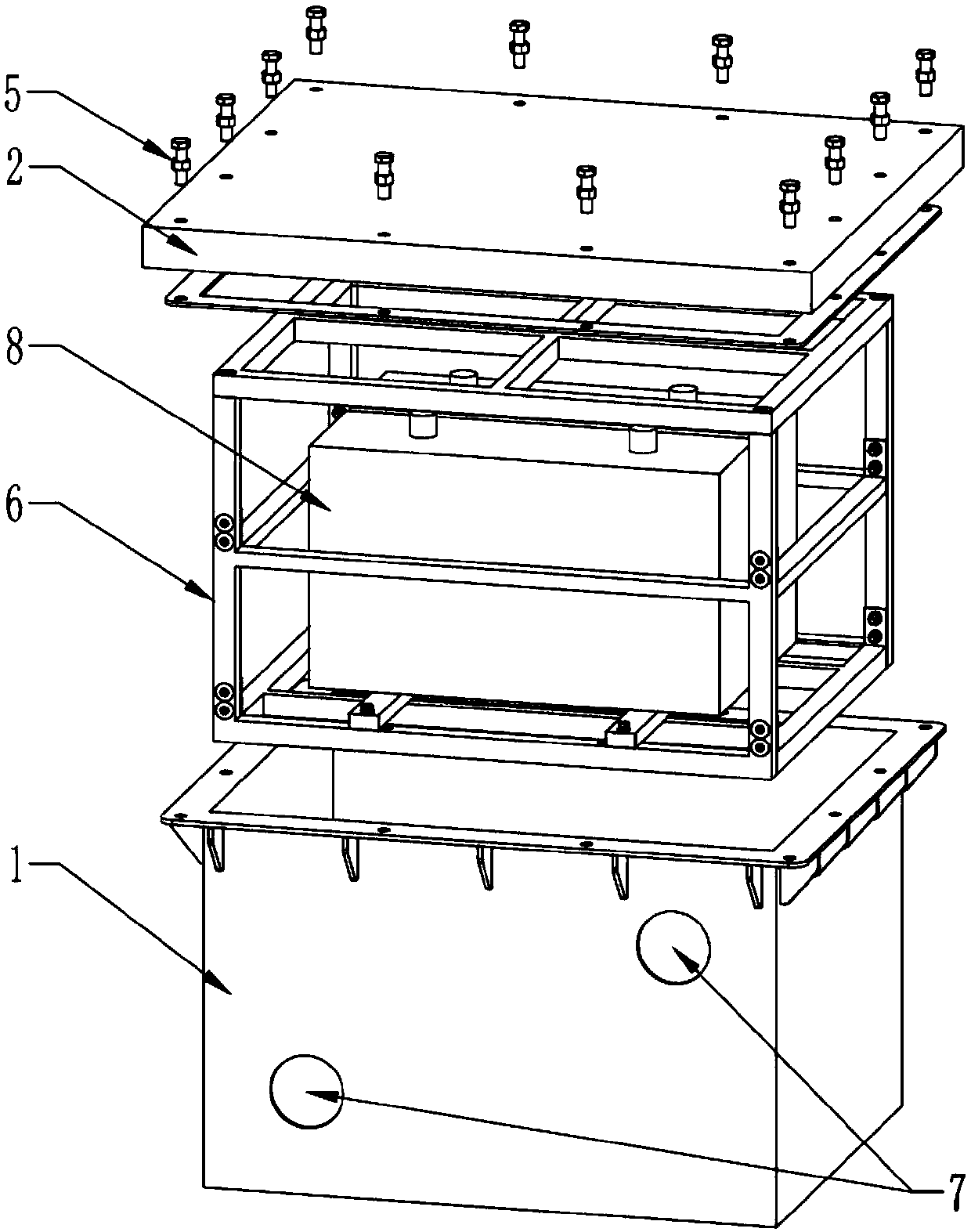

[0111] Such as Figure 1-3 As shown, the present invention provides a buried box, which includes a box body 1, a box cover 2 and a support frame 6; the support frame 6 is arranged in the box body 1, and is connected with the box body 1 and the box cover 2. The inner surface is bonded; the box body 1 and the box cover 2 are made of plastic, and the support frame 6 is made of metal; as Figure 4 with 5 As shown, the support frame 6 includes:

[0112] The upper frame 61, the lower frame 62, the beam 63, the first side frame 64, the second side frame 64', the first outer rail 65 and the second outer rail 65'; the upper frame 61 and the lower frame 62 are arranged in parallel ;

[0113] The first side support 64 includes a bottom and two sides perpendicular to the bottom; the second side support 64' includes a bottom and two sides perpendicular to the bottom;

[0114] The first side bracket 64 and the second side bracket 64' are disposed parallel to each other between the upper...

Embodiment 2

[0126] The method of assembling the buried box described in Embodiment 1 first assembles the support frame 6 without assembling the upper frame 61 temporarily; places the support frame 6 in the box body 1 and puts the battery into the support frame 6, and then installs the upper frame 61 And the sealing cap on the upper frame; Optionally, assemble other accessories; Install the first sealing gasket 3 on the end face that the box body 1 and the box cover 2 are connected to each other, and fasten the box body 1 and the box cover 2 with bolts, that is, realize In the assembly process of the buried box, it can be placed in the underground and other places.

[0127] Specifically, when assembling the supporting frame 6, the specific steps may be as follows:

[0128] The following frame 62 is installed as a benchmark, and the first side support 64 and the second side support 64 ' are first selected, that is, the first side support 64 and the second side support 64 ' are fixedly conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com