Panorama electric sunroof front beam

A panoramic, front beam technology, applied in the field of auto parts, can solve the problems of waste, clumsy front beam, increase the manufacturer's manufacturing cost, etc., and achieve the effect of improving the service life and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

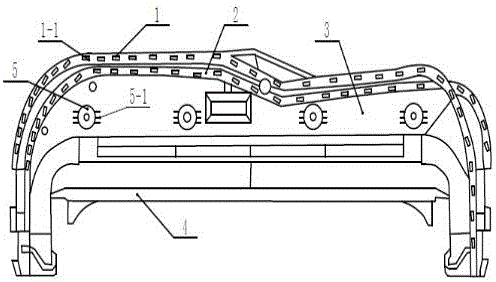

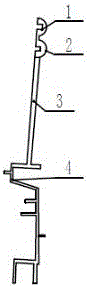

[0011] Depend on figure 1 , figure 2 It is known that a panoramic electric sunroof front beam of the present invention is composed of a flexible shaft guide cover 1, a flexible shaft guide lower cover 2, a front beam body 3, a front beam beam 4, and an interference nut 5. The electric sunroof front beam is made of plastic The flexible shaft conduit upper cover 1 and the flexible shaft conduit lower cover 2 are arranged above the front beam, the front beam beam 4 is arranged under the front beam body 3, and the front beam beam is connected to the flexible shaft conduit upper cover 1 and the flexible shaft conduit upper cover 1. The lowermost end of the flexible shaft conduit lower cover 2 is fixed to the two sides of the front beam crossbeam 4, and the interference nuts 5 are arranged symmetrically on the left and right sides of the front beam body 3, the flexible shaft conduit upper cover 1 and the flexible shaft conduit lower cover 2 The cross-section is a semi-circular smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com