Plastic coated angle iron processing technology and storage battery pole plate solidifying frame adopting plastic coated angle iron

A processing technology and plate curing technology, applied in the direction of lead-acid battery electrodes, coatings, etc., can solve the problems of high maintenance cost, easy corrosion of curing frame, etc., achieve low manufacturing cost, prevent pollution, and improve the effect of curing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

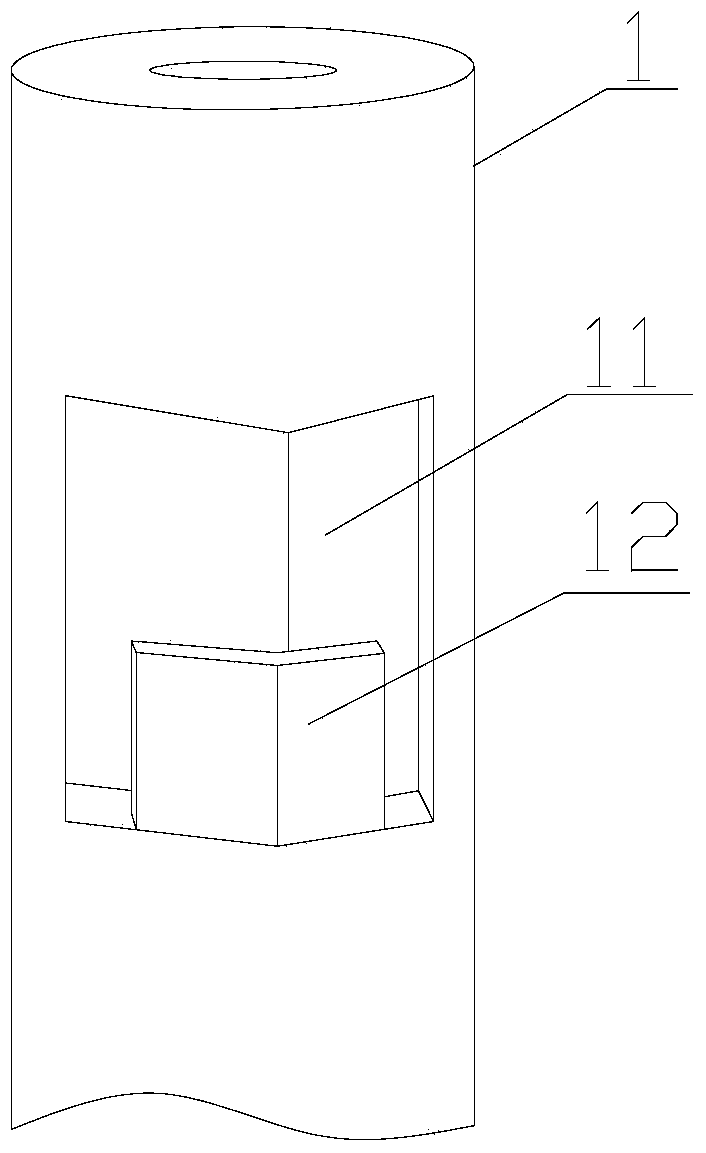

[0028] A kind of hanging plastic angle steel processing technology, comprises the following steps successively:

[0029] A. Remove the rust on the surface of the angle steel;

[0030] B. Heat the resin to a semi-molten state and keep the temperature at 240-280°C;

[0031] C, screw the derusted angle steel in the A step into the resin melt in the semi-molten state in the B step at a speed of 5 revolutions per hour, and slowly screw in when unscrewing;

[0032] D, keeping the angle steel in the resin solution in the semi-molten state for a total of 50 to 70 minutes in step C, while keeping the rotation;

[0033] E. Spin out the semi-molten resin melt at a speed of 5 revolutions per hour, and slowly spin out when unscrewing;

[0034] F. Repeat steps C, D and E 4 to 6 times;

[0035] G, the angle steel that has completed the step F is cooled and solidified in the air.

[0036] Further, in the step A, manual grinding is used to remove rust on the surface of the angle steel.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com