Rotary sealing feeding valve

A technology of rotary sealing and feeding valve, which is applied to rotary conveyors, conveying bulk materials, conveyors, etc., can solve the problems of expansion medium loss environment, pollution, etc., to improve recycling rate, reduce demand, and reduce processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

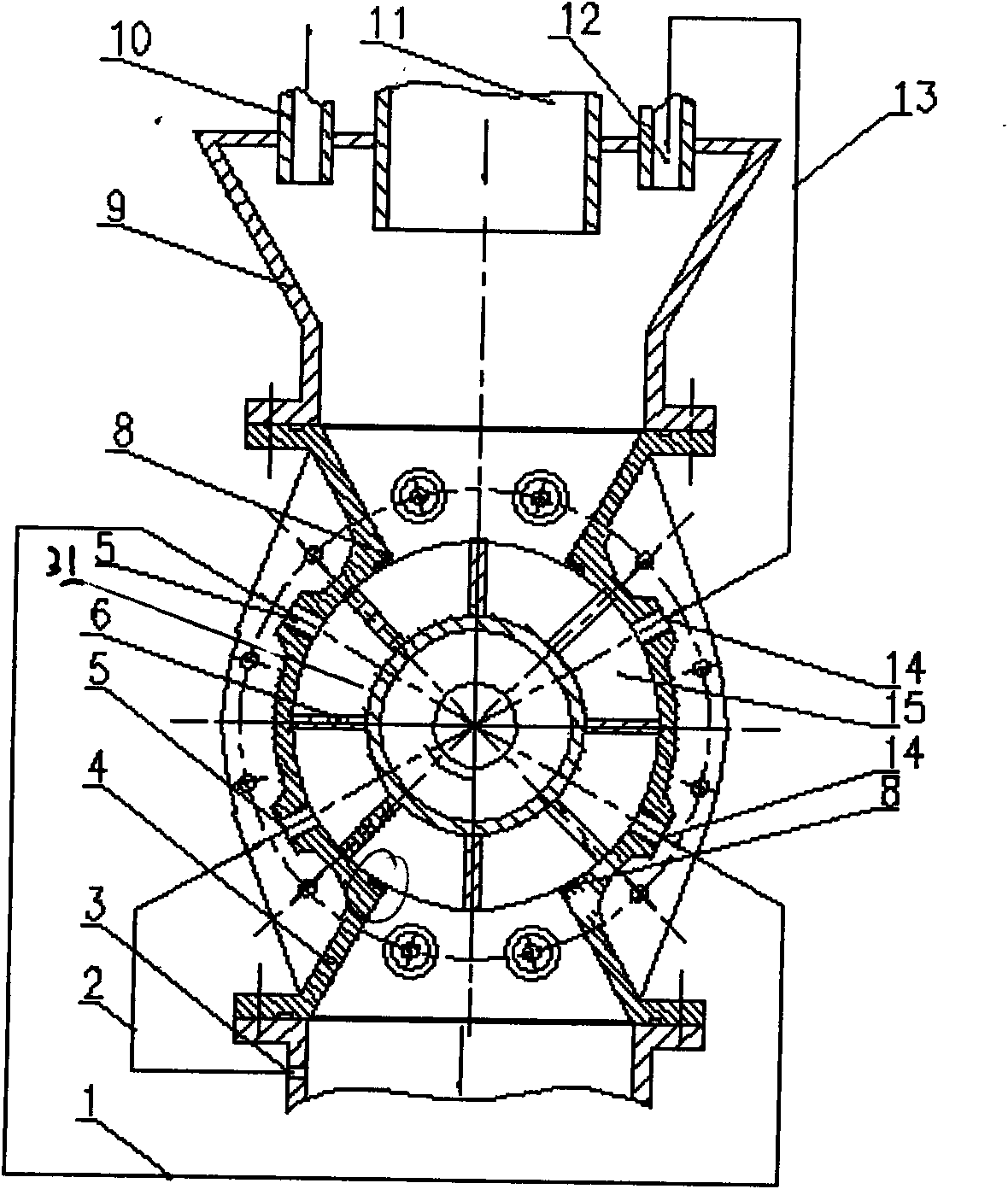

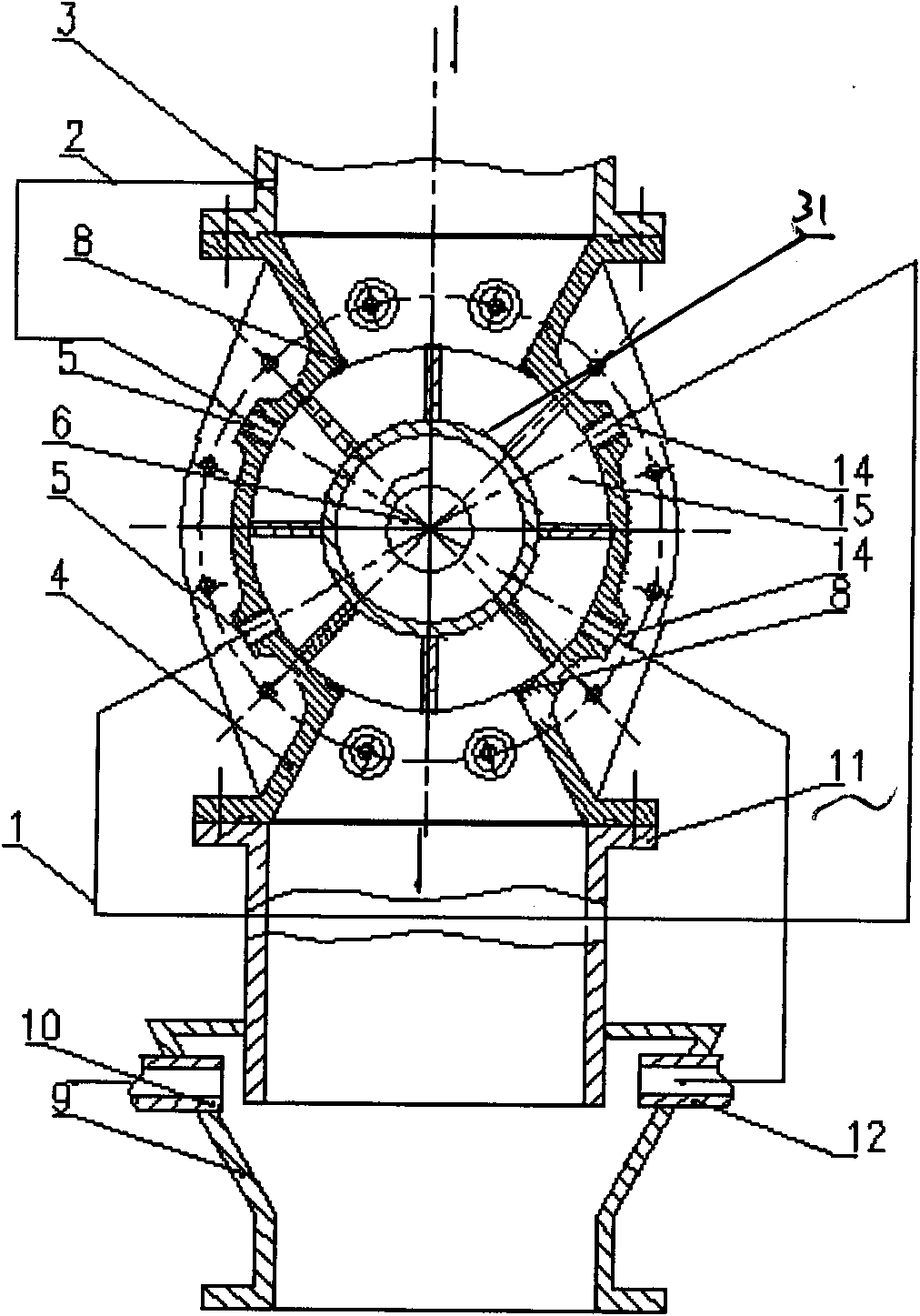

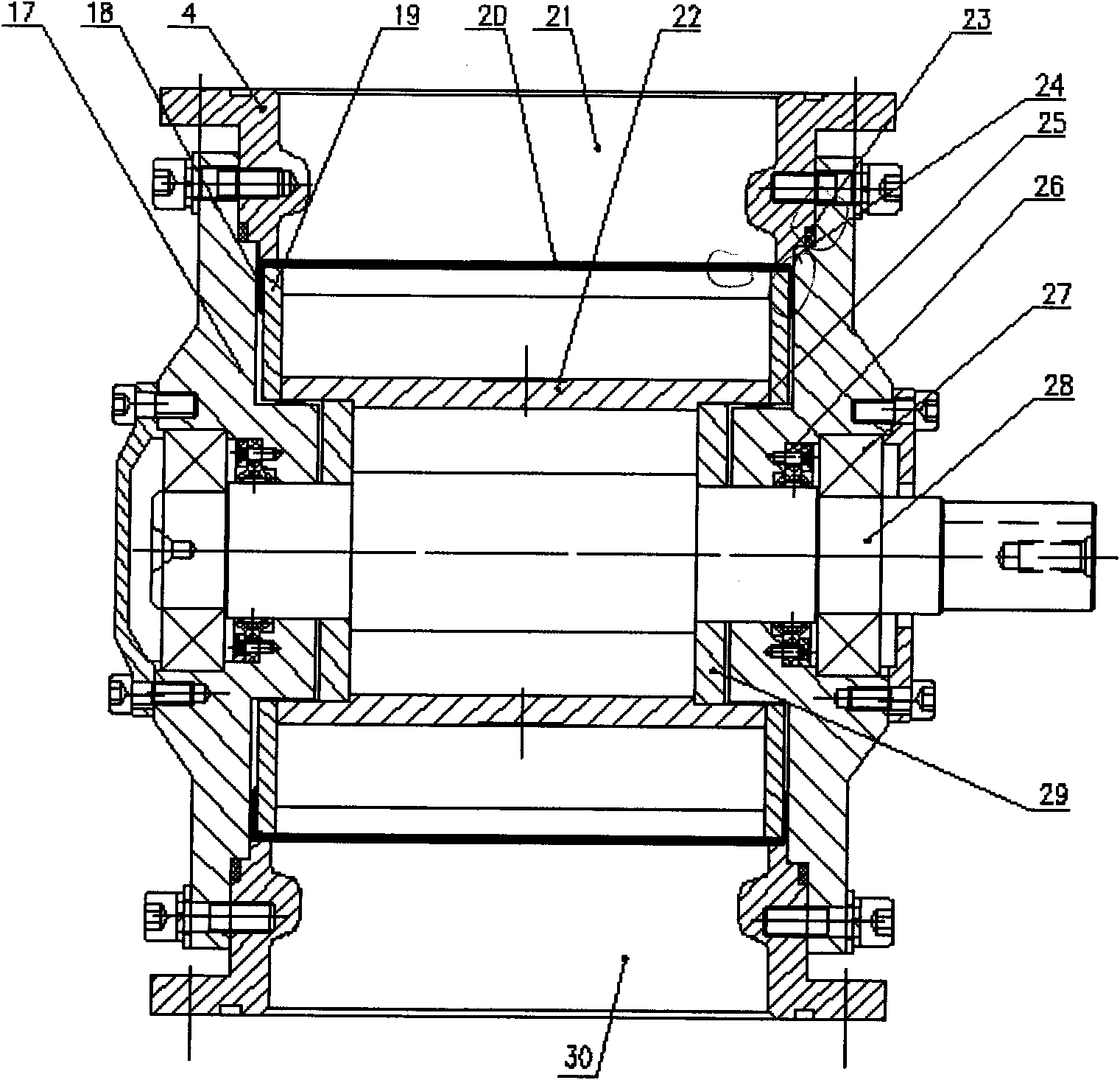

[0015] As shown in the accompanying drawings: a rotary seal feeding valve, including a valve housing 4, the valve housing is provided with a feed port 21 and a discharge port 30 and a Stellite alloy layer 8 surfacing on it, on the valve housing there is The air intake balance port 5 on the side where the pressure increases and the exhaust balance port 14 on the pressure reduction side; the side flanges 17 at both ends of the valve housing are connected to the valve housing through screws, and the cavity formed by the valve housing 4 and the side flanges 17 is installed with The rotor is welded by the main shaft 28, the flange piece 29 and a plurality of volume compartments 15 welded by the blade 6, the end plate 19 and the hollow shaft 22. The rotor is connected to the side by the bearing 27 mounted on the main shaft 28. The flange is installed and fixed; an inverted cone-shaped balance recovery container is welded by the cone shell 9, the feeding pipe 11, the medium recovery i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com