Powder spraying device and method for efficient vanadium extracting process of converter

A powder spraying and converter technology, applied in the field of metallurgy, can solve the problems of poor reaction kinetics in the molten pool, easy to produce extremely cold and extremely hot in the molten pool, and unable to control the temperature continuously, so as to shorten the smelting cycle and improve the kinetics and thermodynamics. Conditions, the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

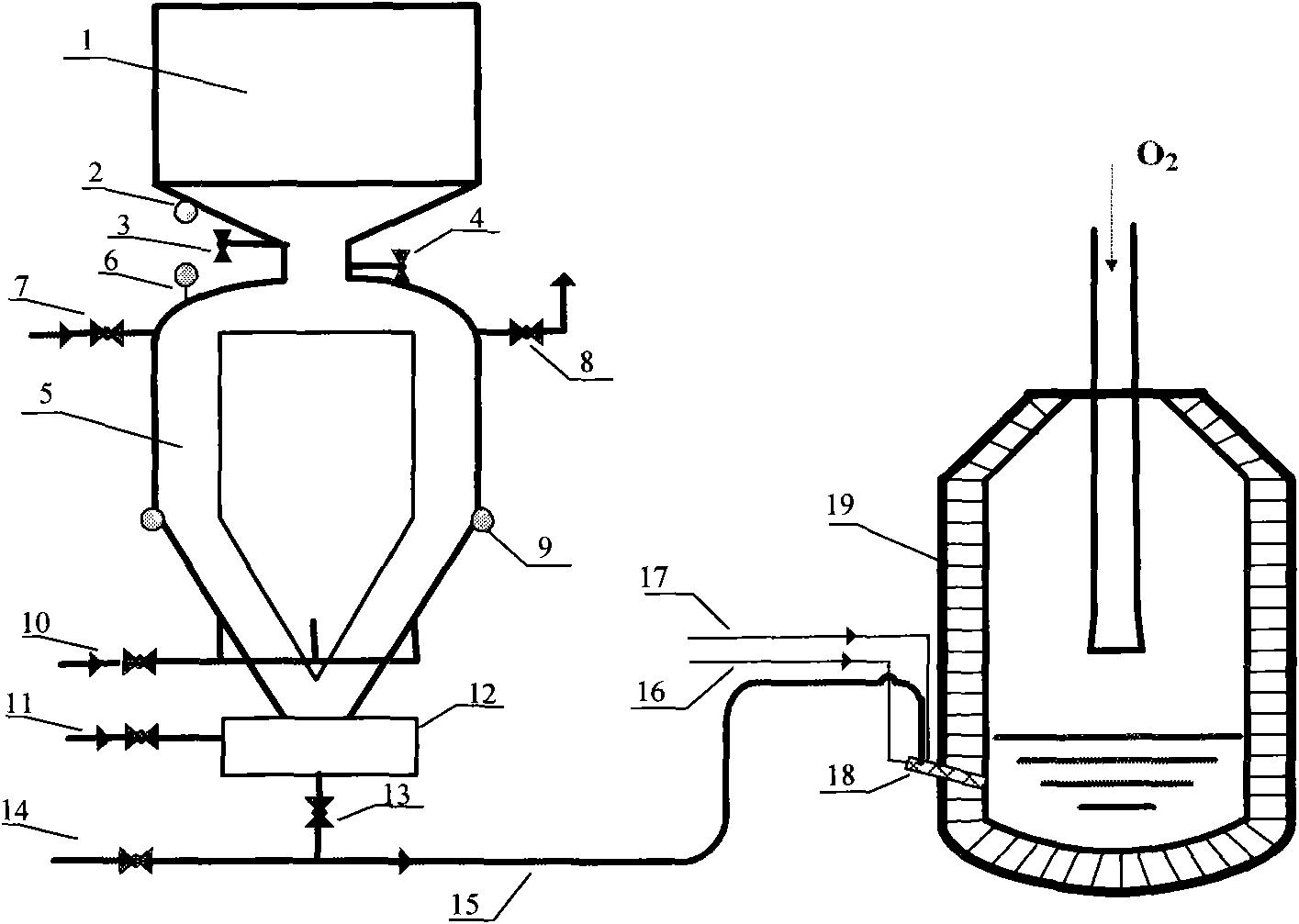

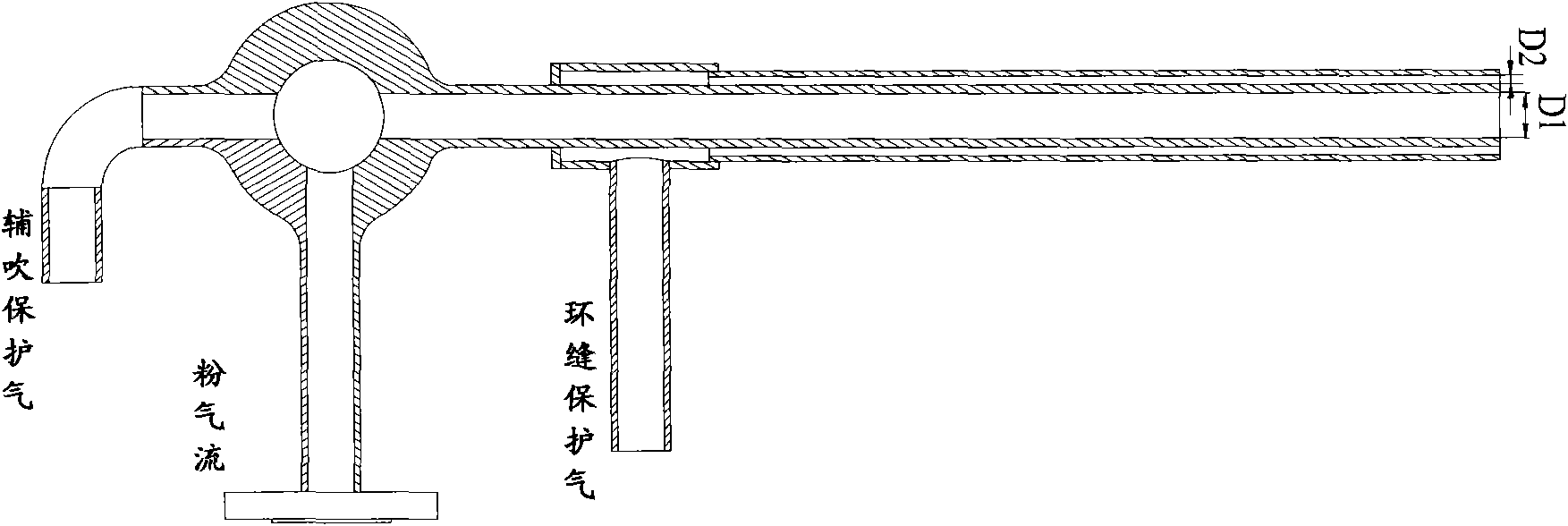

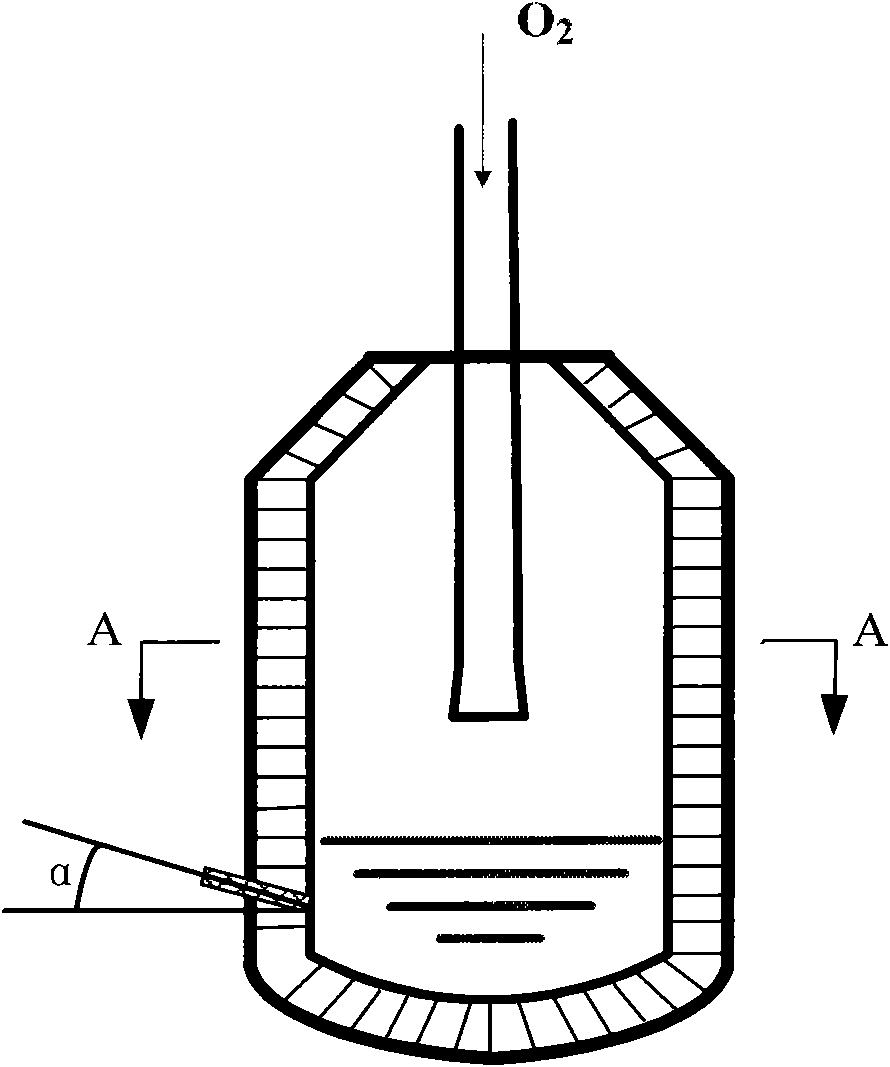

[0018] For a 150-ton vanadium extraction converter, the inner diameter D1 of the powder spray gun is selected to be 25mm, and the ring gap width D2 is 1.5mm. The powder spray gun is installed at 300mm below the liquid surface, the angle α with the liquid surface is 15°, and the installation angle β with the tangent plane of the installation point of the furnace wall is 60°. The powder spray smelting process adopts N 2 As carrier and shielding gas.

[0019] Powder spraying operation control process: ①Open the pressure valve 7 to increase the tank pressure to 0.50-0.55MPa; ②Adjust the flow rate of the carrier gas; ③Open the discharge valve 13; ④Open the fluidization valve 10 to adjust the fluidization pressure to 0.50MPa.

[0020] Feeding period: blowing nitrogen to protect the powder spray gun when loading scrap steel into molten iron, auxiliary blowing flow rate 200-300Nm 3 / h, the carrier gas flow rate is 100Nm 3 / h, the air flow rate of the annular seam is 150~200Nm 3 / h....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com