Clearer production process and preparation system for junked tire

A technology for waste tires and tires, which is applied in the field of clean production process of waste tires and its preparation system, can solve problems such as cost increase, waste of electric energy, and large loss of crushing tools, so as to improve operation efficiency, reduce air escape, and shorten operation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

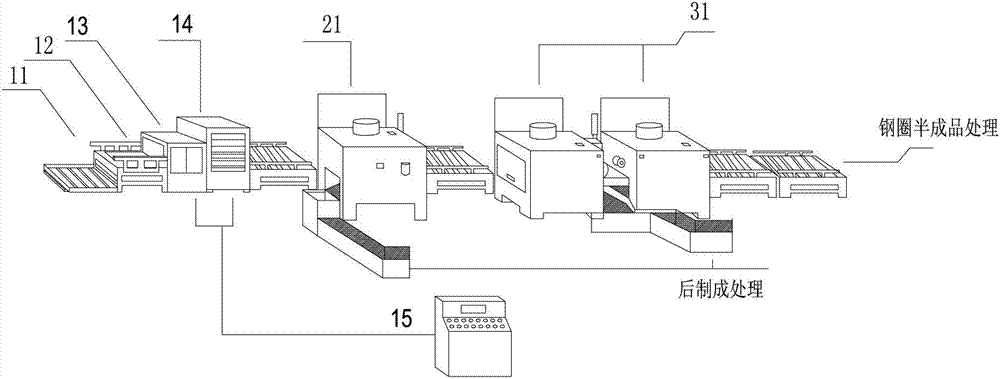

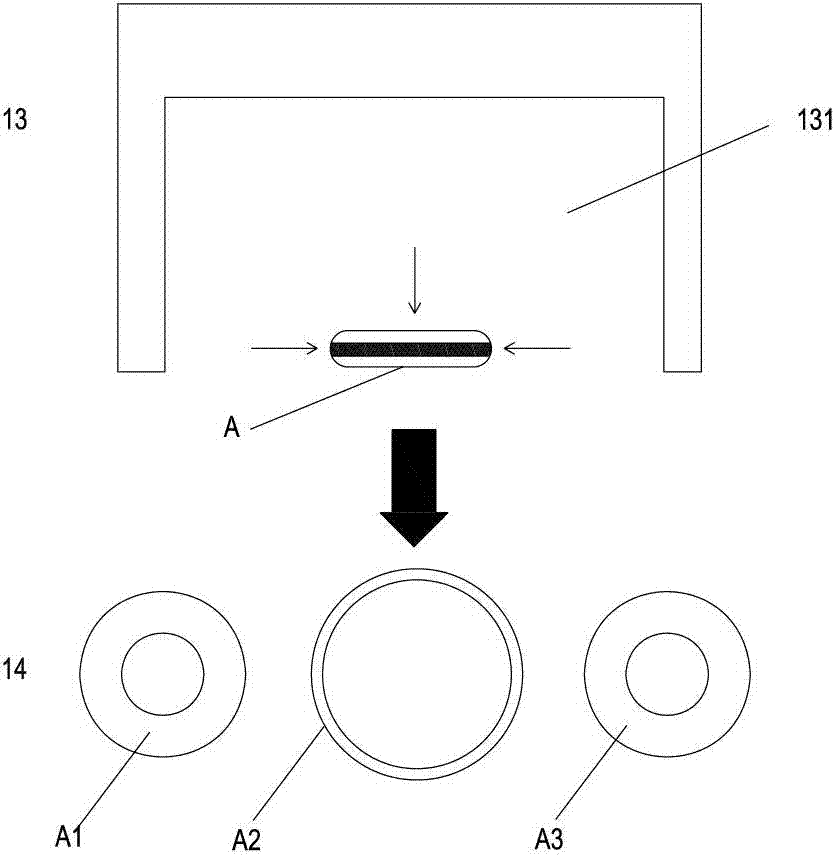

[0052] see figure 1 , the waste tire regeneration processing system of the present invention comprises a preparation unit 11, a measuring unit 12, a cleaning unit 13, a cutting unit 14, a control unit 15, a bead ring sealing intelligent PLC processing unit 21 and a left and right sidewall dual Tower-type airtight intelligent PLC processing unit unit 31.

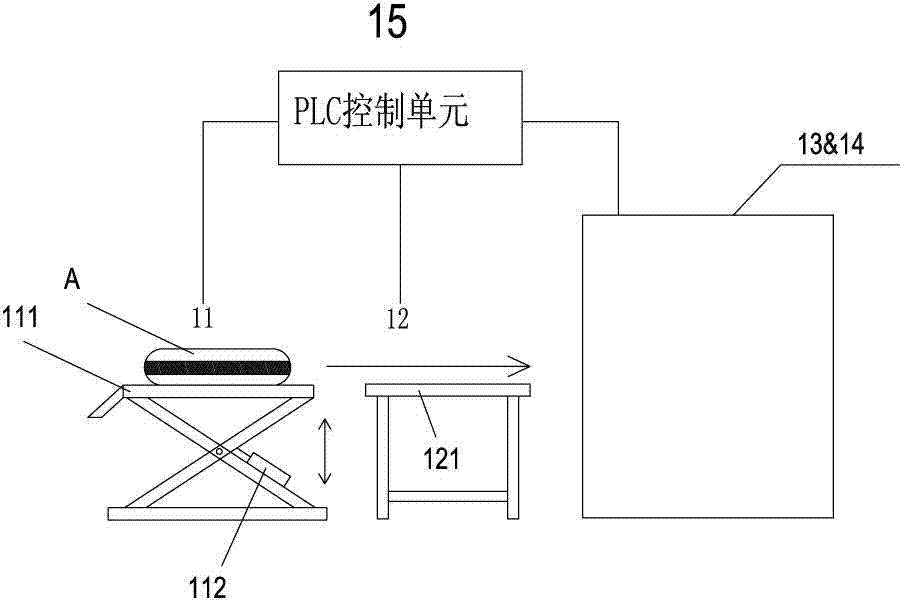

[0053] see figure 2 , the preparation unit 11 has a feeding platform 111 before the weighing platform 121 of the measuring unit 12, and a driving source 112 for moving the feeding platform 111 up and down. The waste tire A is laid flat, and is lifted to the same height as the weighing platform 121 by being pushed by the driving source 112 .

[0054] The measuring unit has a weighing platform for measuring the weight of the waste tire A, and a dimensioning platform for measuring the appearance size of the waste tire A. The weighing platform and the dimensioning platform will measure the measured appearance size and weight t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com