A kind of plant polysaccharide thermal insulation airgel material and preparation method

A thermal insulation and aerogel technology, which is applied in the field of konjac polysaccharide thermal insulation aerogel and konjac polysaccharide thermal insulation aerogel, can solve the problems of environmental pollution, refractory decomposition, human body injury, etc. To achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]A kind of konjac polysaccharide thermal insulation aerogel, which is made of the following materials in weight or volume:

[0051]

[0052]A method for preparing konjac polysaccharide thermal insulation aerogel, which is characterized in that it is prepared according to the following steps:

[0053](1) Dissolve chitosan in 50mL 1v / v% acetic acid solution and stir for 30min at room temperature to obtain solution A;

[0054](2) Take a certain amount of deionized water and add glycerin, and add starch, konjac glucomannan, auxiliary gum, straw, and nano calcium carbonate under the condition of mechanical stirring at 800 rpm, and then quickly stir evenly to obtain solution B;

[0055](3) Mix solution A with solution B to obtain solution C, and stir solution C at 60°C for 3.5 hours to obtain a transparent viscous gel;

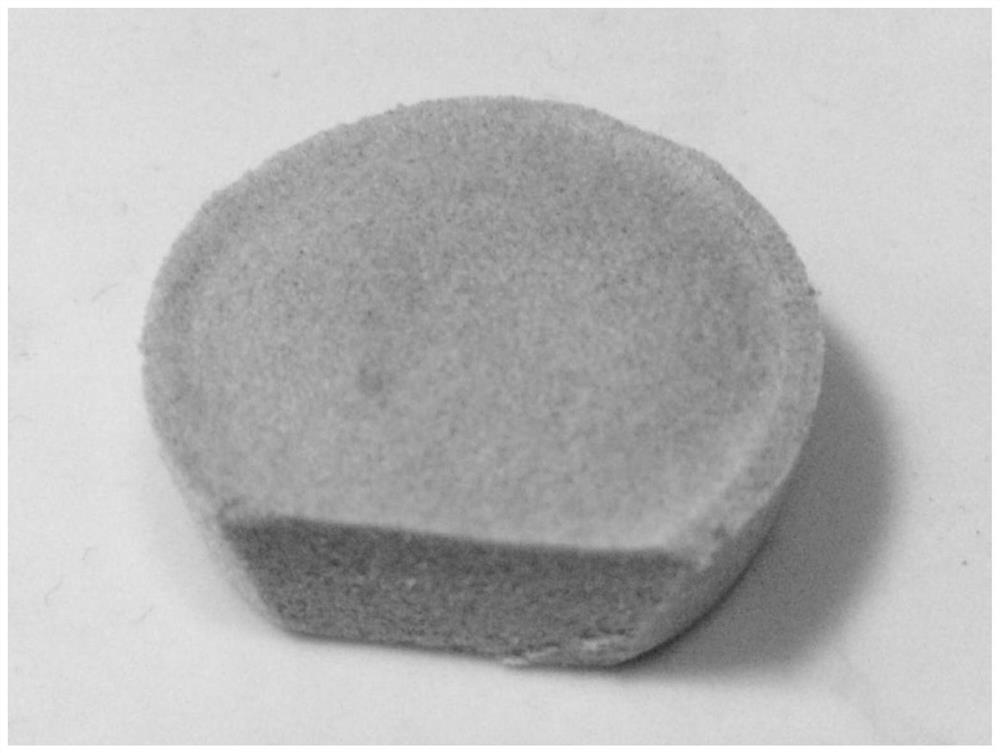

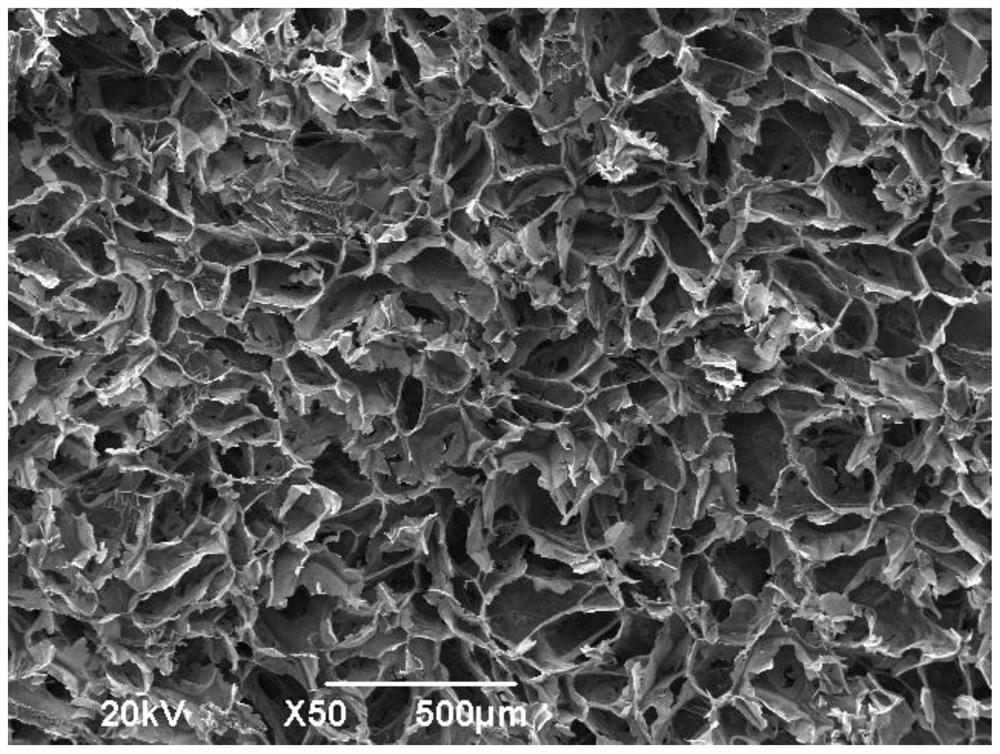

[0056](4) Homogenize the stirred transparent viscous gel and pour it into the mold to cool it into a gel;

[0057](5) Pre-freezing for 24h at -30℃;

Embodiment 2-8

[0059]Examples 2-8: According to the raw material components in Table 1, and the process parameters in Table 2, the preparation steps are the same as those in Example 1. The performance indexes of the prepared konjac polysaccharide thermal insulation aerogel are shown in Table 3.

[0060]Table 1: Raw material composition table of the embodiment

[0061]

[0062]

[0063]Table 2. Process parameter table

[0064] Example 2 Example 3 Example 4 Example 5 Example 6 Example 7 Example 8 Stirring time of solution A (min) 45303555506030 Speed (rpm) 70060080090012001500400 Stirring temperature of solution C (℃) 75707580859060 Stirring time of solution C (h) 0.80.511.52.530.5 Pre-freezing temperature (℃) -15-10-20-25-45-60-12 Pre-freezing time (h) 86102015224 Vacuum (Pa) 11010012086908060 Freeze drying temperature (℃) -35-30-45-20-50-60-35 Freeze drying time (h)16142818243012

[0065]Table 3. Product performance table

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com