Comprehensive simulation test system for railway hopper car

A simulation test system and hopper car technology, applied in the field of railway hopper car comprehensive simulation test system, can solve the problems of inability to analyze and simulate the live operation of hopper cars, and achieve the effect of solving the problem of material recovery and processing, compact layout and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

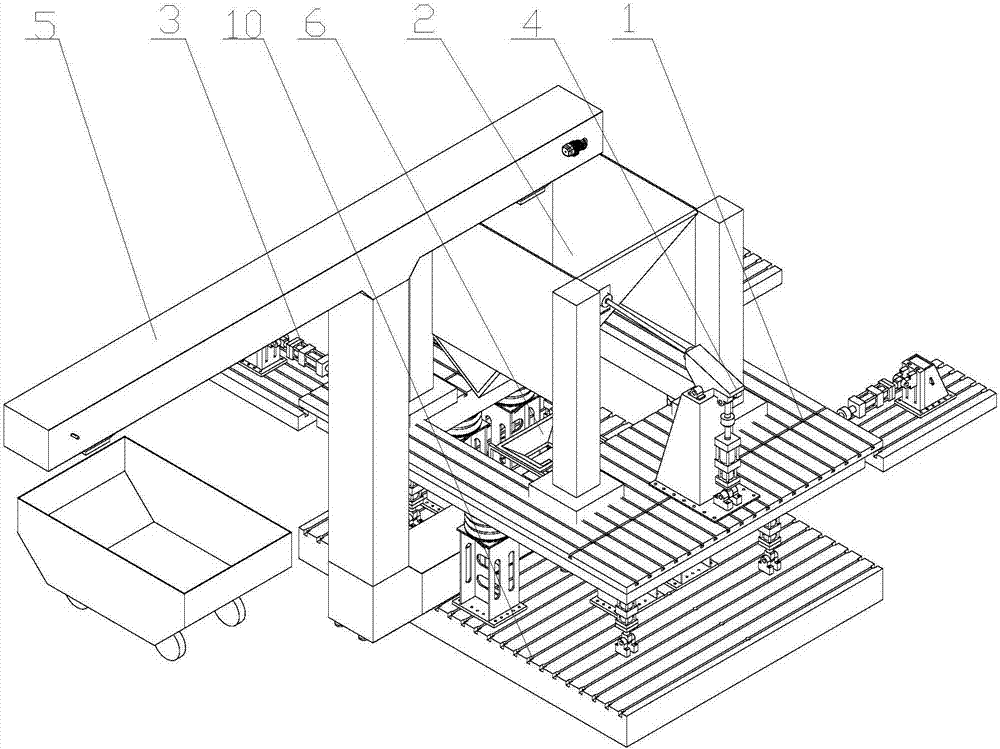

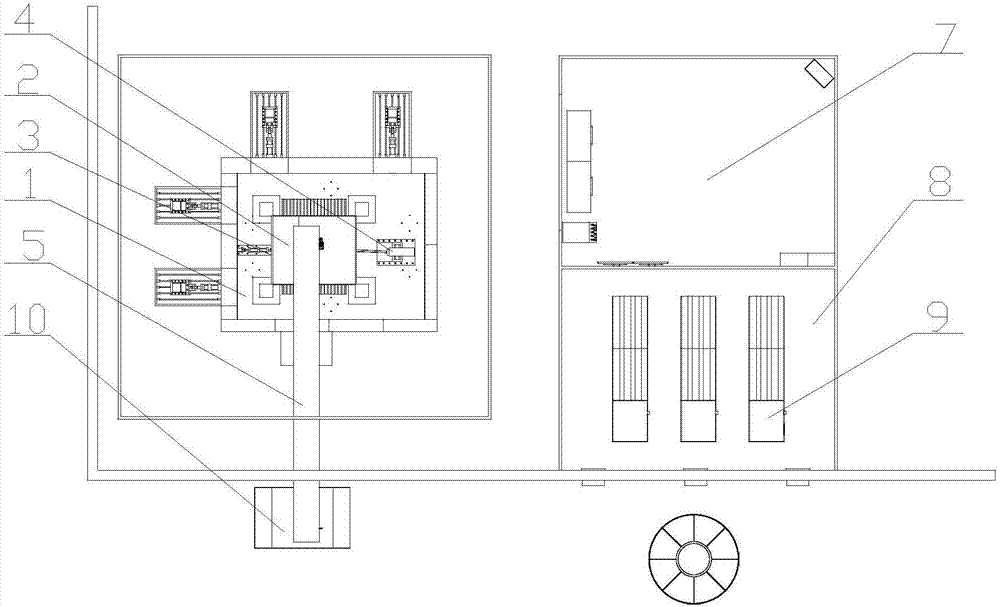

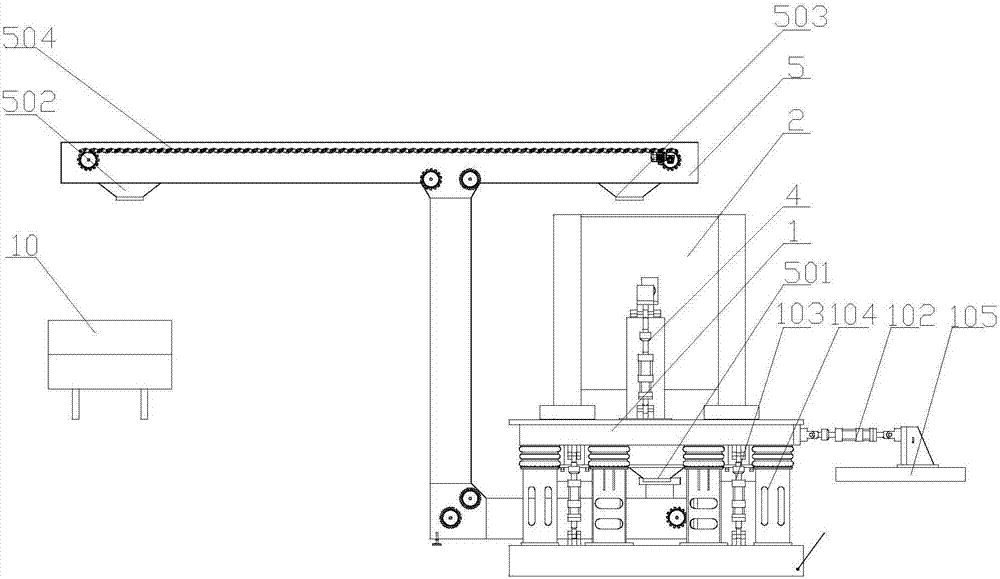

[0036] see Figure 1-Figure 3 , the invention discloses a comprehensive simulation test system for railway hopper cars, the test system includes an orthogonal six-degree-of-freedom excitation platform 1, a simulated hopper car silo 2, a bottom door opening and closing mechanism 3, a longitudinal load simulation loading mechanism 4 and a material circulatory system5.

[0037]The simulated hopper car silo 2 is installed on the upper end of the orthogonal six-degree-of-freedom vibration platform 1, and the orthogonal six-degree-of-freedom vibration platform 1 is provided with a blanking port 6 opposite to the simulated hopper car silo 2, and the bottom door opening and closing mechanism 3 It is connected with the bottom door of the simulated hopper car silo 2, the bottom end of the longitudinal load simulating loading mechanism 4 is vertically fixed on the orthogonal six-degree-of-freedom excitation platform 1, and the top of the longitudinal load simulating loading mechanism 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com