Large-scale steel cylinder cofferdam structure

A steel cylinder, large-scale technology, applied in the field of large-scale steel cylinder cofferdam structure, can solve the problems of non-recyclable use, complicated construction procedures, and low water-stop protection degree, and achieve high recycling rate, simple reinforcement measures, and easy construction high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

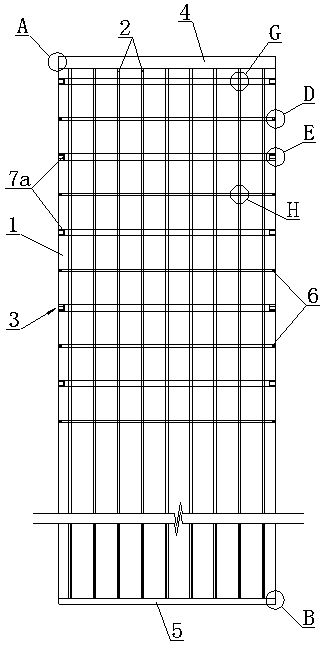

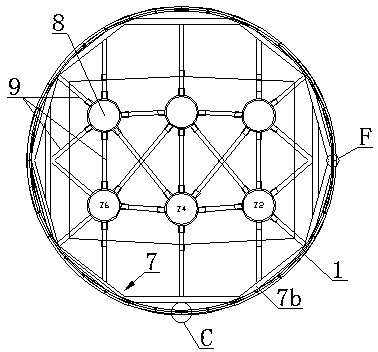

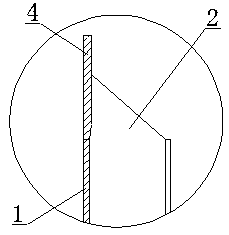

[0030] refer to figure 1 with figure 2 As shown, a large-scale steel cylinder cofferdam structure of the present invention includes a cylinder body 1 of steel structure, and the thickness of the cylinder body 1 is 16-25mm; on the inner wall of the cylinder body 1, there are several vertical reinforcing ribs distributed along the circumferential interval 2. The vertical reinforcing ribs 2 can satisfy the vertical force transmission of the entire cylinder body 1 during the vibration sinking and uplifting period; on the inner wall of the exposed part of the cylinder body 1, a number of transverse reinforcement structures 3 are arranged at intervals along the axial direction; The inner diameter of the body 1 is 15-30 meters. The top elevation of the cylinder body 1 shall be determined according to the sea level and waves in the open sea, and the bottom elevation shall be determined according to the stability of the structure under the corresponding soil layer and the water-stop r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com