Production method of pseudo-boehmite with large pore volume

A pseudo-boehmite and production method technology, which is applied to the preparation of alumina/aluminum hydroxide, alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems of large fluctuations in product quality, long reaction time, and production problems. In order to achieve the effect of inhibiting spontaneous hydrolysis reaction, realizing continuous production and promoting neutralization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

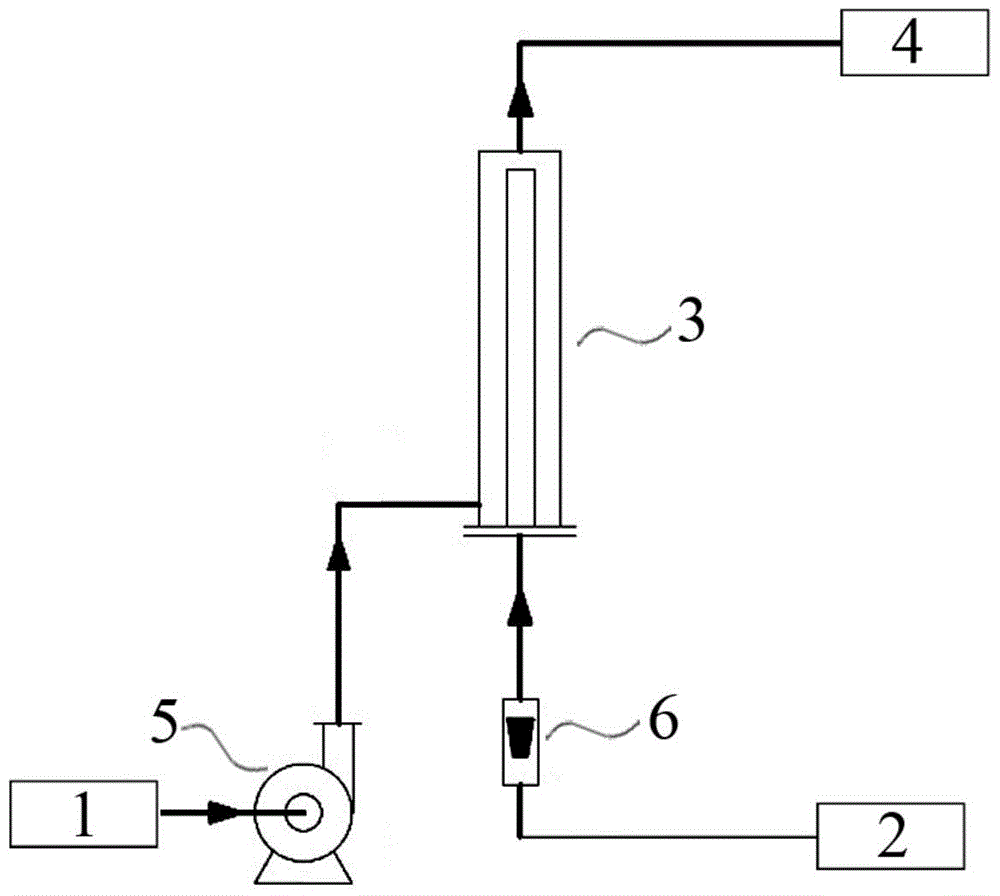

Method used

Image

Examples

Embodiment 1

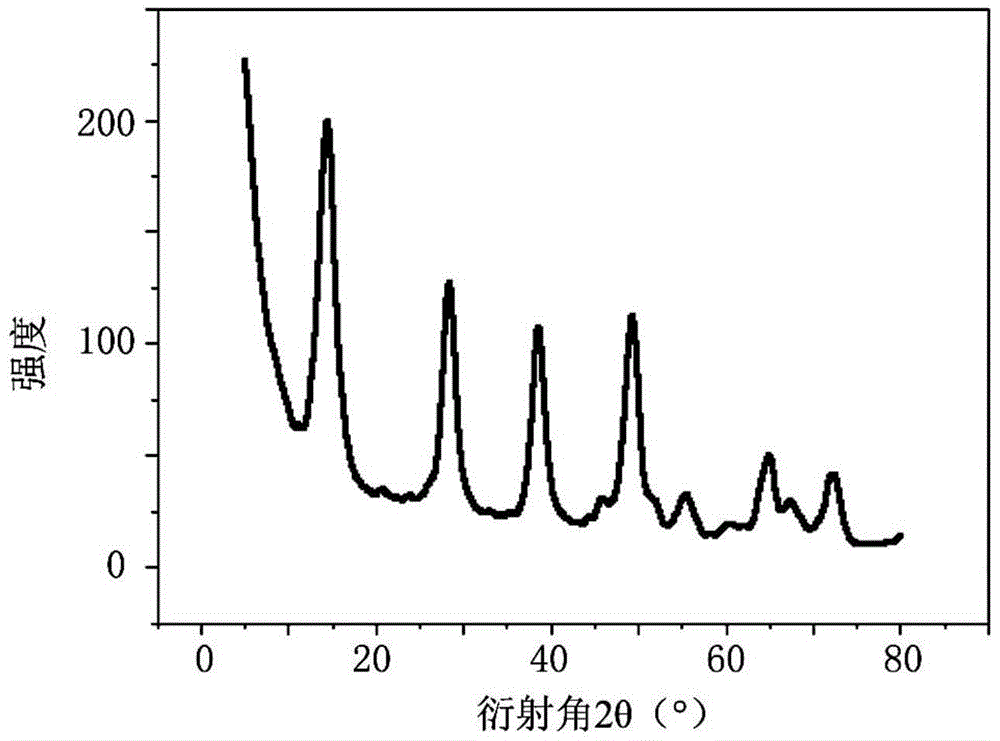

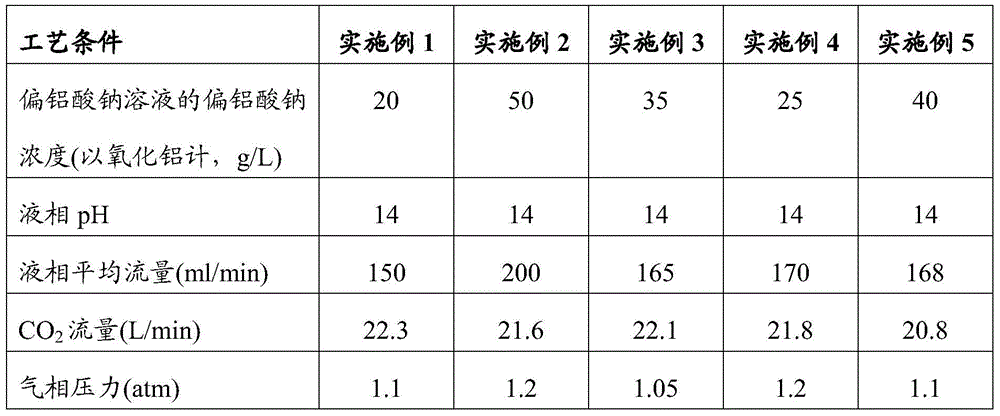

[0069] See Table 1 for other process conditions of Examples 1-5, and see Table 2 for the performance parameters of the obtained pseudo-boehmite. The XRD pattern of the pseudo-boehmite prepared in Example 1 is shown in figure 2 .

[0070] Table 1

[0071]

[0072]

[0073] Table 2

[0074] Performance parameters Example 1 Example 2 Example 3 Example 4 Example 5 Pore volume V(ml / g) 0.65 0.85 0.72 1.01 0.92 Specific surface area (m 2 / g)

375.53 365.01 347.56 298.33 310.25

[0075] The performance parameters of the pseudo-boehmite obtained in Examples 1-5 have little change, which shows that the method of the present invention can obtain pseudo-boehmite products with stable quality.

[0076] In addition, Examples 1-5 were repeated 5 times respectively, and the variation range of the performance parameters of the obtained pseudo-boehmite was less than 0.5%, which indicated that the method of the present invention had good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com