Preparation method of pseudo-boehmite

A technology of pseudo-boehmite and meta-aluminate is applied in the field of producing pseudo-boehmite by carbonization, which can solve the problems of large fluctuation of product quality, easy scarring of production equipment, small production capacity, etc., and achieves inhibition of spontaneous hydrolysis. reaction, beneficial to industrial application, and the effect of promoting neutralization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the pseudo-boehmite of the present invention includes a gelation step. Optionally, the preparation method of the pseudo-boehmite of the present invention may further include an aging step, a separation washing step and a drying step.

[0042]

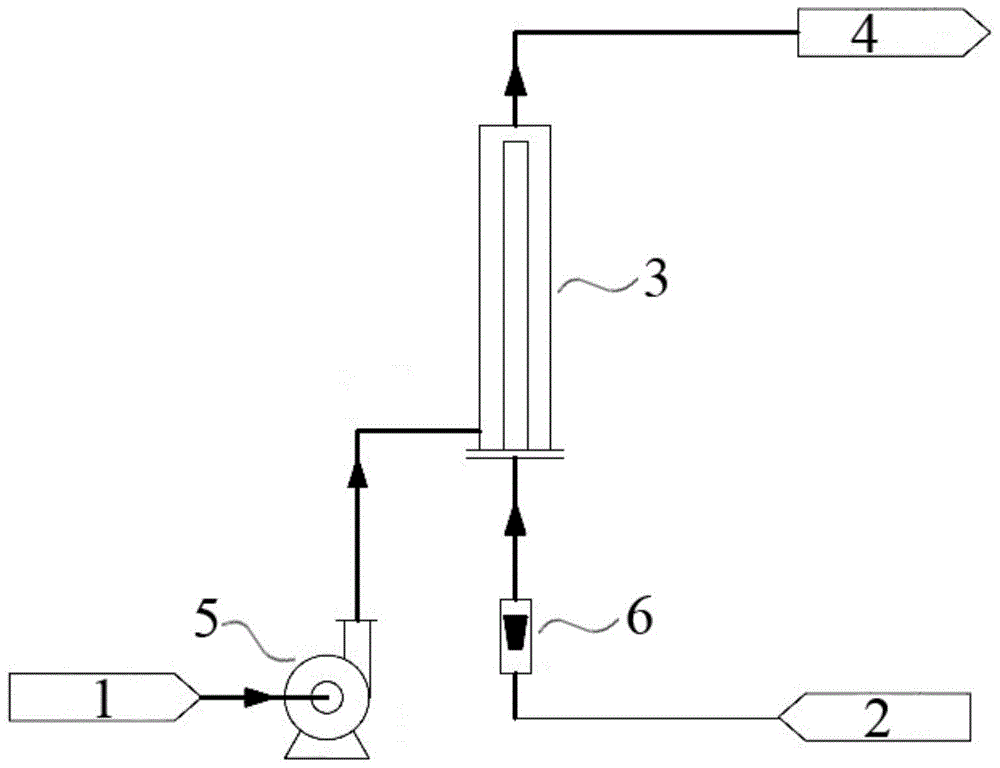

[0043] The gel forming step of the present invention is to contact the metaaluminate solution with carbon dioxide gas in an inorganic membrane reactor to form a reaction product.

[0044] In the present invention, the inorganic membrane reactor may be selected from tubular inorganic membrane reactors or hollow fiber inorganic membrane reactors. The tubular type and the hollow fiber type mentioned here both refer to the shape of the inorganic membrane. Preferably, the inorganic membrane reactor of the present invention is a tubular inorganic membrane reactor or a hollow fiber inorganic membrane reactor.

[0045] In the present invention, the inorganic membrane reactor includes a casing and an inorgani...

Embodiment 1

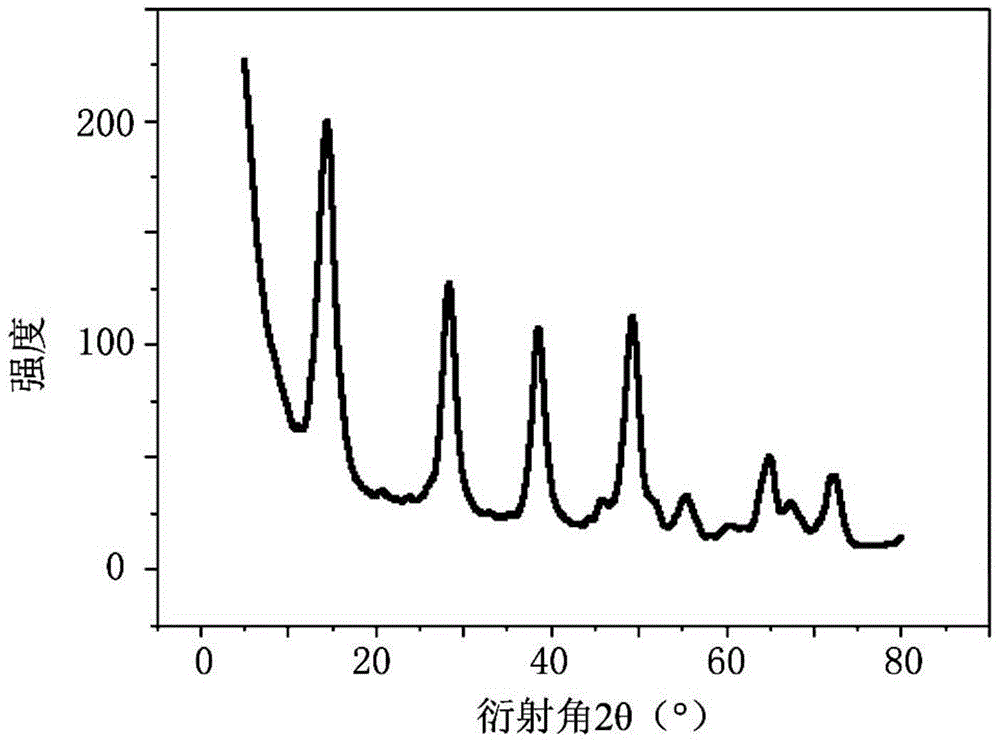

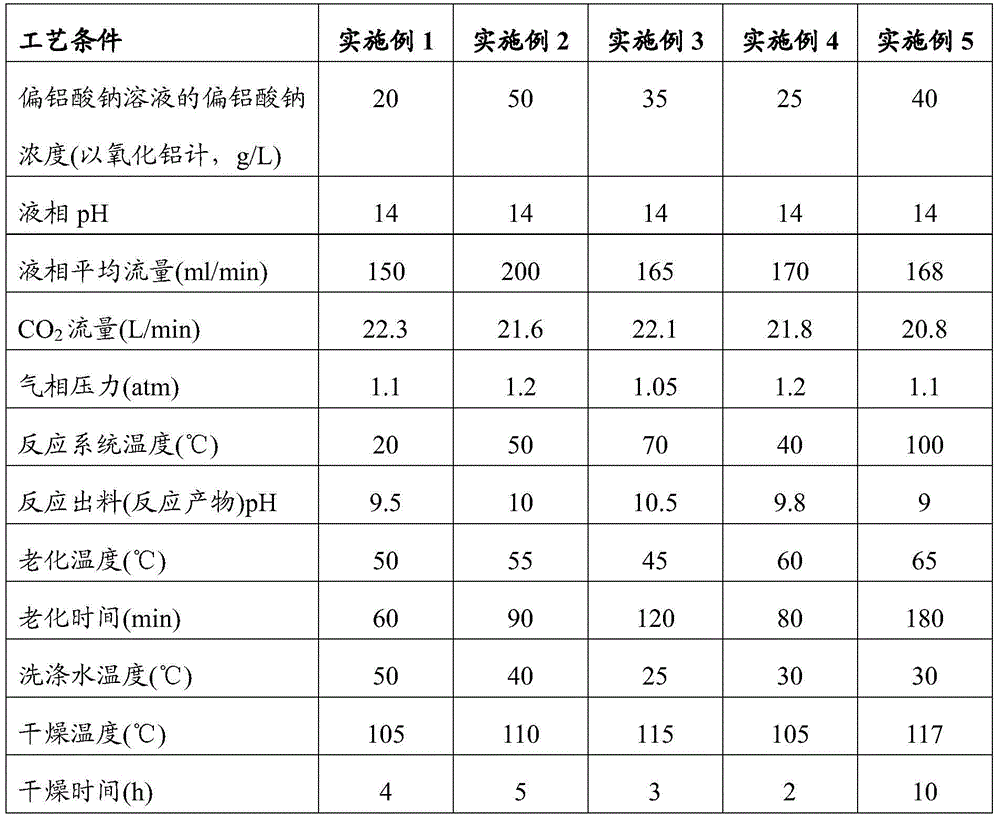

[0067] See Table 1 for other process conditions of Examples 1-5, and see Table 2 for the performance parameters of the obtained pseudo-boehmite. The XRD pattern of the pseudo-boehmite prepared in Example 1 is shown in figure 2 .

[0068] Table 1

[0069]

[0070] Table 2

[0071] performance parameter Example 1 Example 2 Example 3 Example 4 Example 5 Pore volume V(ml / g) 0.35 0.40 0.41 0.42 0.45 Specific surface area (m 2 / g)

440.50.33 387.80 347.56 303.33 280.87

[0072] The performance parameters of the pseudo-boehmite obtained in Examples 1-5 have little change, which shows that the method of the present invention can obtain pseudo-boehmite products with stable quality.

[0073] In addition, Examples 1-5 were repeated 5 times respectively, and the variation range of the performance parameters of the obtained pseudo-boehmite was less than 3%, which indicated that the method of the present invention had good repeatabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com