A low-chlorine photothermal molten salt production process and production device

A production process and molten salt technology, which are applied in the field of low-chlorine photothermal molten salt production process and production devices, can solve the problems of high manufacturing cost, the chlorine content cannot meet the requirements of molten salt products, and the production cannot be stabilized, and the equipment can be reduced. Corrosion, the effect of shortening the reaction residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

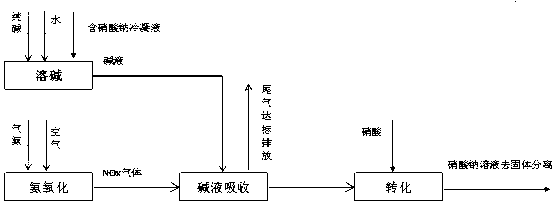

preparation example Construction

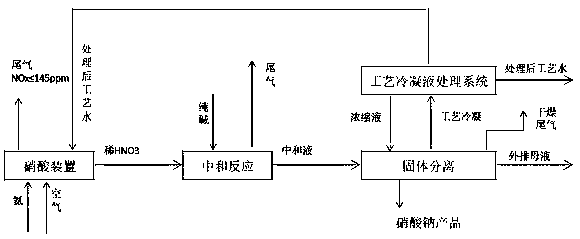

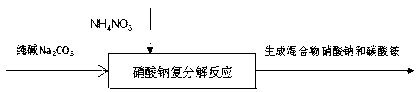

[0070] a) Preparation of molten salt solution: the alkaline liquid and nitric acid solution are sent into the neutralization reactor as raw materials, and the neutralization reactor adopts a spray tube reactor structure with a static mixer, and the alkaline liquid and the The nitric acid solution is directly subjected to continuous neutralization reaction in the ejector and static mixer, and the steam generated by the neutralization reaction is used for heat recovery and used in the evaporation and crystallization process; among them, the raw material of the alkali liquid can be directly obtained from the alkali liquid device Obtain, nitric acid solution raw material can obtain from dilute nitric acid plant, described alkali liquid is sodium hydroxide or potassium hydroxide solution, and the reaction process of described alkali liquid and nitric acid solution in the neutralization reactor is an exothermic reaction, The operating pressure is 1bar(a)~4bar(a), the operating temper...

Embodiment 1

[0080] process such as Figure 5 Shown: the nitric acid solution (55%wt~65%wt concentration) in the dilute nitric acid tank is pumped in the eductor of the neutralization reactor through the dilute nitric acid pump, simultaneously the sodium hydroxide solution (32 % concentration) is pumped into the heat exchanger by the lye pump to preheat the lye and then added to the injector unit of the neutralization reactor, and the dilute nitric acid solution and sodium hydroxide solution in the injector unit of the neutralization reactor are added in molar ratio Add after 1:1 metering, dilute nitric acid solution and sodium hydroxide solution are mixed in the injector unit and static mixer unit of the neutralization reactor and neutralize to generate sodium nitrate, the operating pressure is 1bar(a)~4bar (a), the operating temperature is about 103°C to 130°C, and the pH value is controlled at 6.5-7.5; the generated sodium nitrate and the generated water vapor enter the separator of the...

Embodiment 2

[0086] process such as Figure 5 Shown: the nitric acid solution (55%wt~65%wt concentration) in the dilute nitric acid tank is pumped into the ejector unit of the neutralization reactor through the dilute nitric acid pump, and the potassium hydroxide solution ( 32% or so concentration) is pumped into the heat exchanger to preheat the lye through the lye pump and then added to the injector unit of the neutralization reactor, and the dilute nitric acid solution and potassium hydroxide solution in the injector unit of the neutralization reactor are added by mole Add after metering at a ratio of 1:1, dilute nitric acid solution and potassium hydroxide solution are mixed in the neutralization reactor injector unit and static mixer unit and undergo neutralization reaction to generate potassium nitrate, the operating pressure is 1bar (a) ~ 4bar (a), the operating temperature is about 103°C to 130°C, and the pH value is controlled at 6.5-7.5; the generated potassium nitrate and the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com