Process and device for continuously producing powdery sodium alpha-olefin sulfonate

A technology of sodium alkenyl sulfonate and alkenyl sulfonate, which is applied in feeding device, chemical industry, sulfonate preparation and other directions, can solve the problems of low product content, large energy consumption, large investment, etc. The effect of high content, simple equipment and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

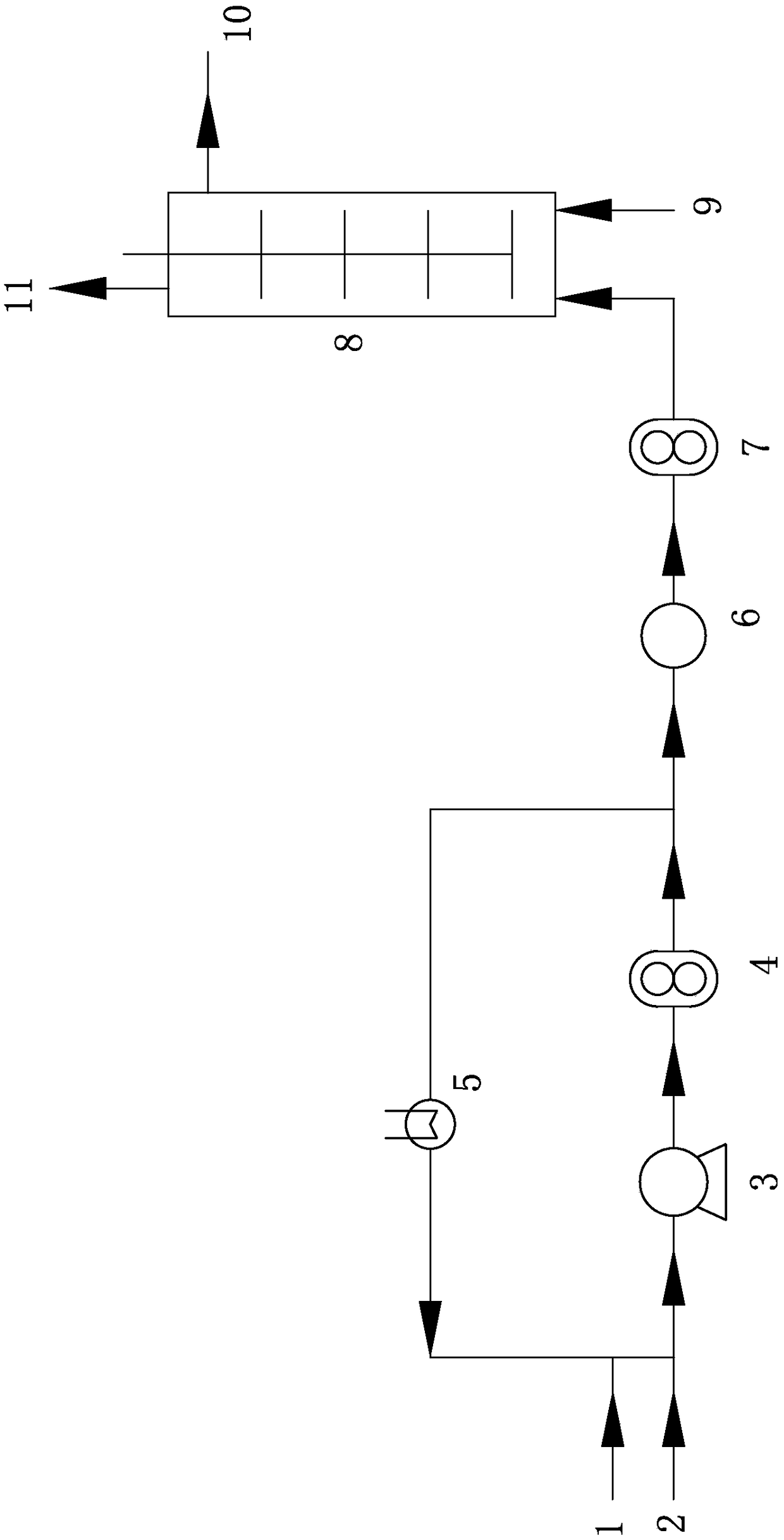

Method used

Image

Examples

Embodiment 1

[0042] 1t / h powdery AOS production process

[0043] The 1t / h powder AOS production device consists of a shear pump, a Φ0.5*5m hydrolysis column with a rotating speed of 10RPM and a stirring paddle, a delivery pump, a back pressure valve and a heater. is 0.3 MPa.

[0044] Alkenyl sulfonate and caustic soda enter the neutralizer for neutralization at the flow rate of 870kg / h and 130kg / h respectively and about 10t / h of neutralized recycled materials, and are circulated by the neutralization pump and heated by the heater. Control the temperature to 140°C, and after the neutralization system pressure reaches 0.3MPa, it will enter the hydrolysis column from the bottom at a speed of 1t / h through the hydrolysis delivery pump through the back pressure valve. At the same time, 0.6MPa steam is introduced from the bottom of the hydrolysis column at a speed of 50kg / h.

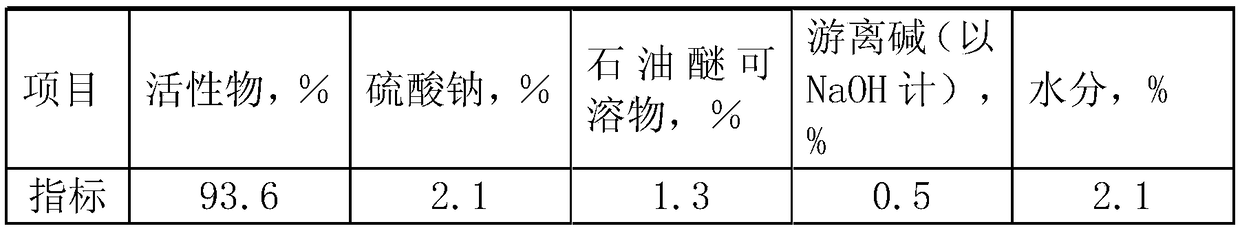

[0045] In the hydrolysis column, the neutralized material with a viscosity of about 10000cp is hydrolyzed under the act...

Embodiment 2

[0048] Embodiment 2: 2t / h powdery AOS production process

[0049]The 2t / h powdery AOS production device consists of a shear pump, a Φ0.8*4m hydrolysis column with a rotating speed of 10RPM and a 5-layer stirring paddle, a delivery pump, a back pressure valve and a heater. The valve pressure is 0.25MPa.

[0050] Alkenyl sulfonate and caustic soda enter the neutralizer for neutralization at the flow rate of 1740kg / h and 260kg / h respectively and about 20t / h of neutralized recycled materials, and then circulate through the neutralization delivery pump and heat by the heater. Control the temperature to 145°C, and after the neutralization system pressure reaches 0.25MPa, it will enter the hydrolysis column from the bottom at a speed of 2t / h through the hydrolysis delivery pump through the back pressure valve. At the same time, 0.65MPa steam is introduced from the bottom of the hydrolysis column at a speed of 120kg / h.

[0051] In the hydrolysis column, the neutralized material with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com