Production method for high-purity lithium metal and special equipment thereof

A production method and technology of special equipment, applied in the field of metal preparation, can solve the problems of long reaction time, low purity of intermediate products, long process process, etc., and achieve the effects of shortening synthesis reaction time, improving product purity, and shortening process process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

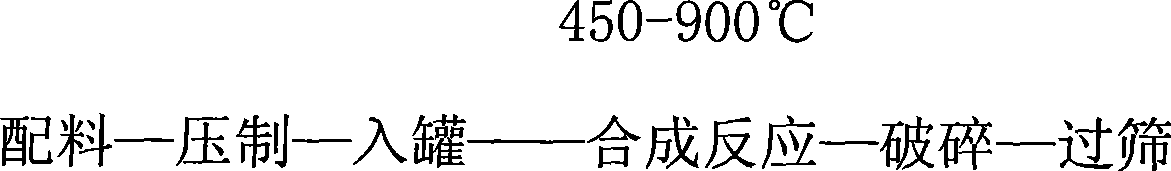

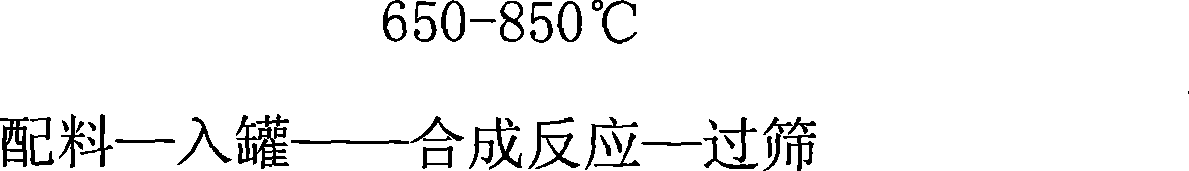

Method used

Image

Examples

Embodiment 1

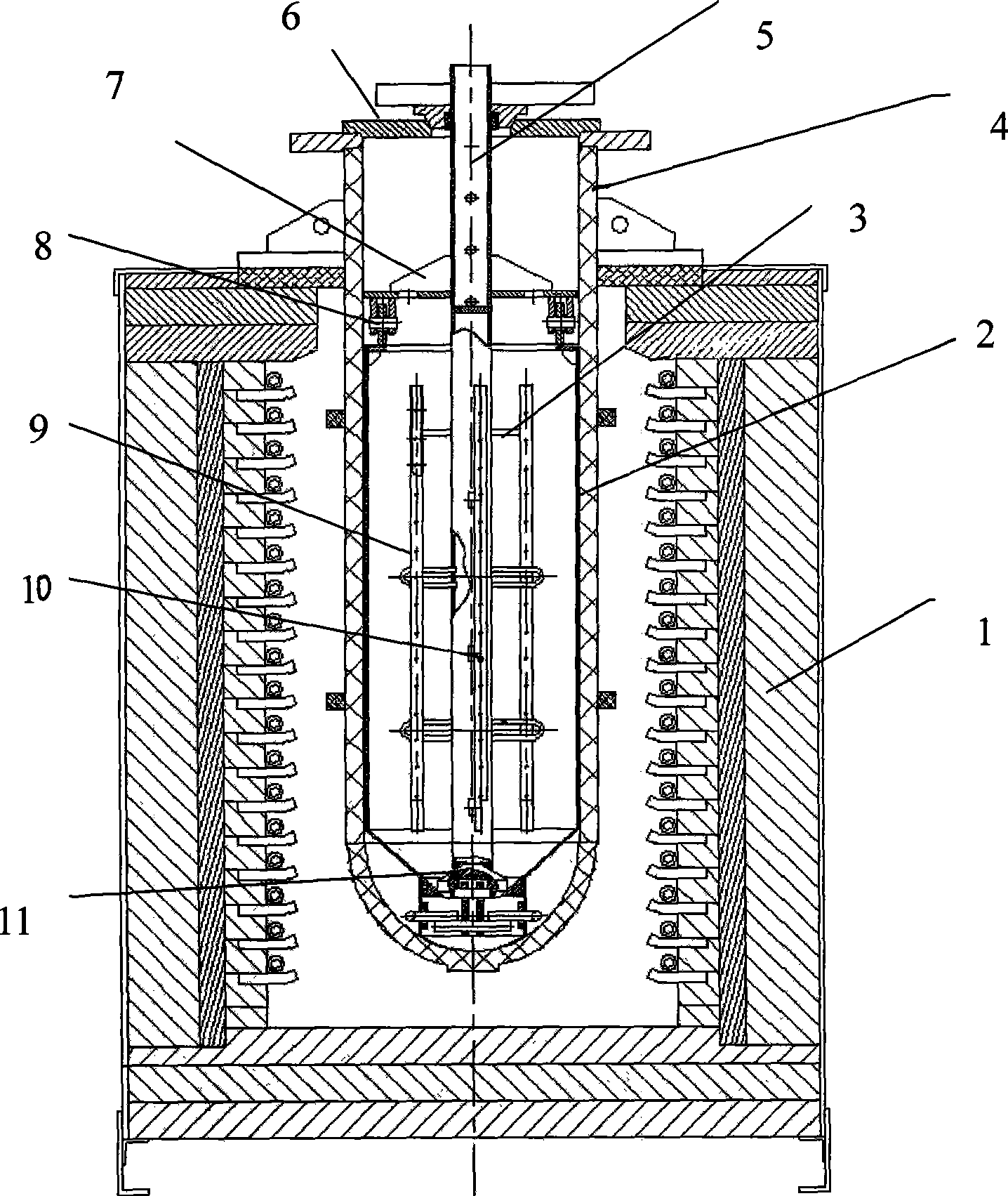

[0028] The production method of high-purity metallic lithium, used equipment comprises mixing machine, synthesis reactor and high-temperature electric furnace etc., and wherein synthesis reactor is as image 3 The shown is composed of an electric furnace 1, a reaction tank 4, an inner tank 2, and a mixer. The electric furnace 1 is equipped with a reaction tank 4, and the inner tank 2 of the reaction tank 4 is movable in the tank 4. The bottom of the inner tank 2 is With a discharge port, a flap valve 11 is installed at the discharge port, and a mixer is installed in the inner tank 2, and the mixer is as Figure 4 As shown, the main shaft 5 is connected to the branch pipe 9 through the bracket 3, and the main shaft 5 and the branch pipe 9 are provided with an exhaust hole 10. There is a limiting plate 7 with an exhaust passage. The bottom of the limiting plate 7 is equipped with a roller 8. The roller 8 is placed on the upper edge of the inner container 2 and can rotate along t...

Embodiment 2

[0039] Adopt the production equipment described in embodiment 1, carry out the production of high-purity lithium metal according to following raw material and technique:

[0040] The first step of synthesis reaction: the raw materials lithium carbonate and lime are fully mixed in a high-efficiency mixer, then put into a synthesis reaction kettle, and roasted at a temperature of 700 ° C to obtain a fired intermediate product after removing carbon dioxide and water, and then pass sieve spare;

[0041] The second reduction reaction: Add ferrosilicon as a reducing agent to the intermediate product obtained in the first step, mix it and press it into a spherical or columnar shape, and then carry out the reduction reaction at a high temperature of 1200 ° C and a vacuum of 0.2 Pa to obtain lithium metal .

Embodiment 3

[0043] According to the method described in Example 1 to produce high-purity metal lithium, the specific raw material ratio and process conditions are as follows:

[0044] The first step of synthesis reaction: raw material Li 2 CO 3 (1# material) and AL 2 o 3 (2# material) Feed material at a molar ratio of 1:1, furnace temperature is 850°C, and the reaction is completed in 6 hours;

[0045] The second reduction reaction: the reduction reaction at a high temperature of 1200 ° C and a vacuum of 5 Pa, the raw material Li 2 O.Al 2 o 3 The molar ratio to Al is 3:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com