Method for preparing photocatalyst with monatomic Pt embedded into covalent organic framework and application of photocatalyst

A covalent organic framework, photocatalyst technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, catalyst activation/preparation, etc. Catalytic water splitting has problems such as low hydrogen production efficiency, low visible light absorption and utilization rate, etc., to achieve the effects of high reusability, short synthesis reaction time, and simple and convenient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

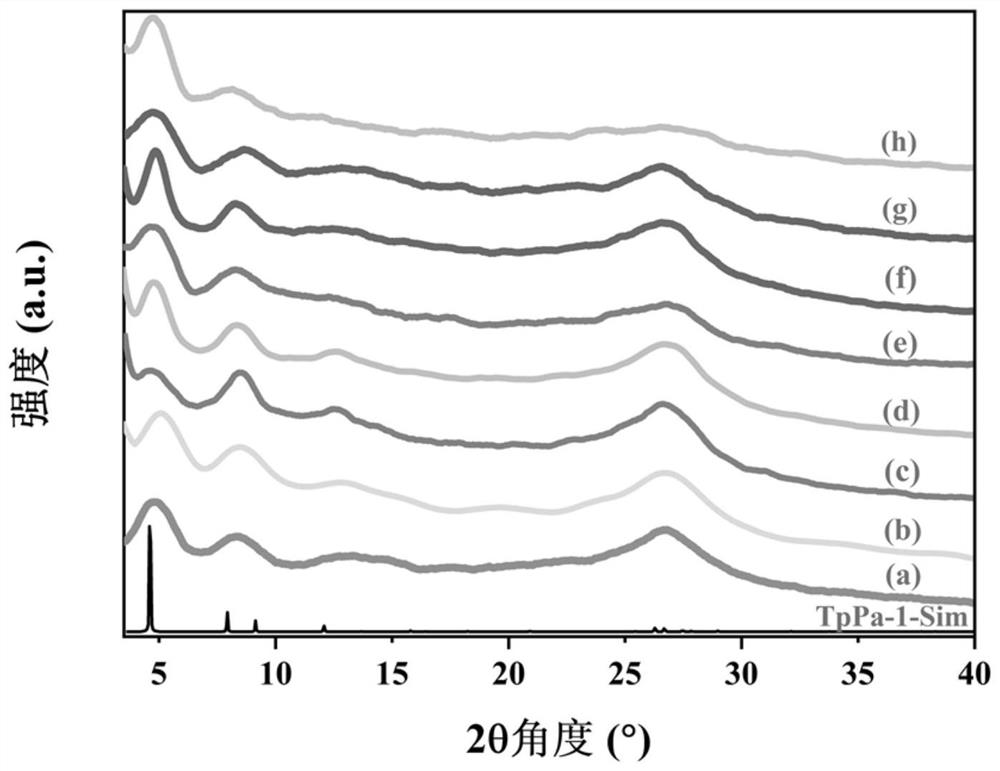

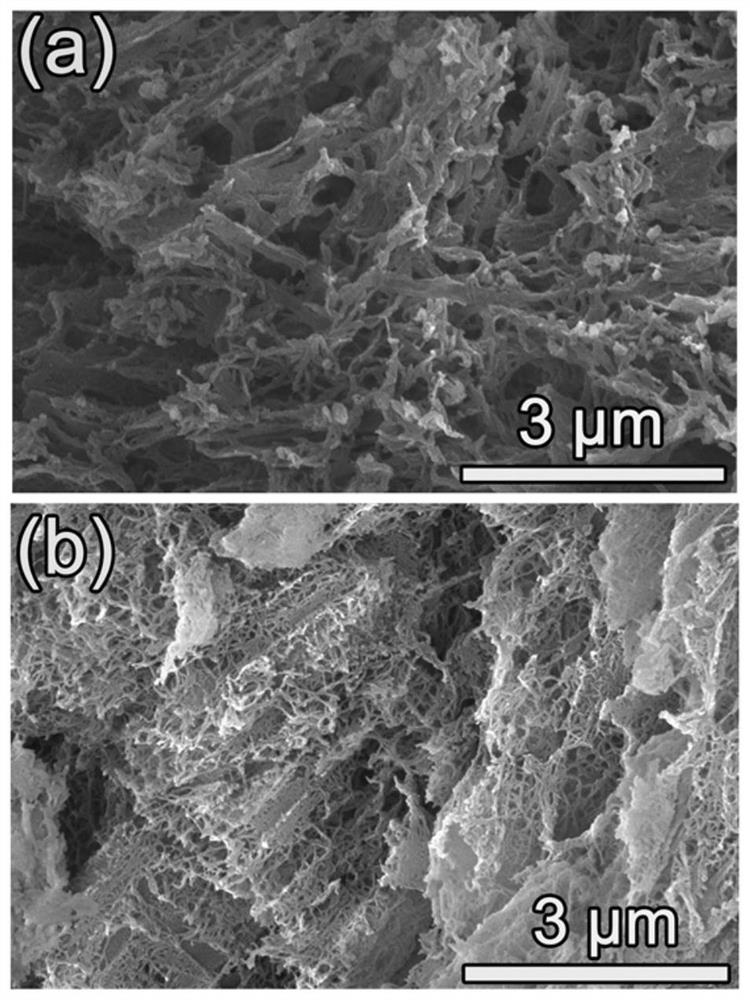

[0042] Example 1 Preparation of TpPa-1-COF Photocatalyst

[0043] Weigh 434.8mg (ie 5mmol) of p-toluenesulfonic acid and 48.6mg (ie 0.9mmol) of p-phenylenediamine, grind for 5min, weigh 64.9mg (ie 0.6mmol) of 1,3,5-trialdehyde-based m-benzene Trisphenol, grind for 10 min, add 100 µL of deionized water dropwise, continue grinding to obtain an orange mud; transfer to a watch glass, react at 170 °C to obtain a dark red product, cool to room temperature, use N,N- Dimethylacetamide, deionized water, and acetone were washed in sequence for 2 each, and the product was dried in a blast drying oven at 60 °C overnight; fully ground for 20-30 min, and then incubated at 125 °C for 1 h under the protection of high-purity Ar. Cool to room temperature with the furnace to obtain a deep red photocatalyst.

Embodiment 2

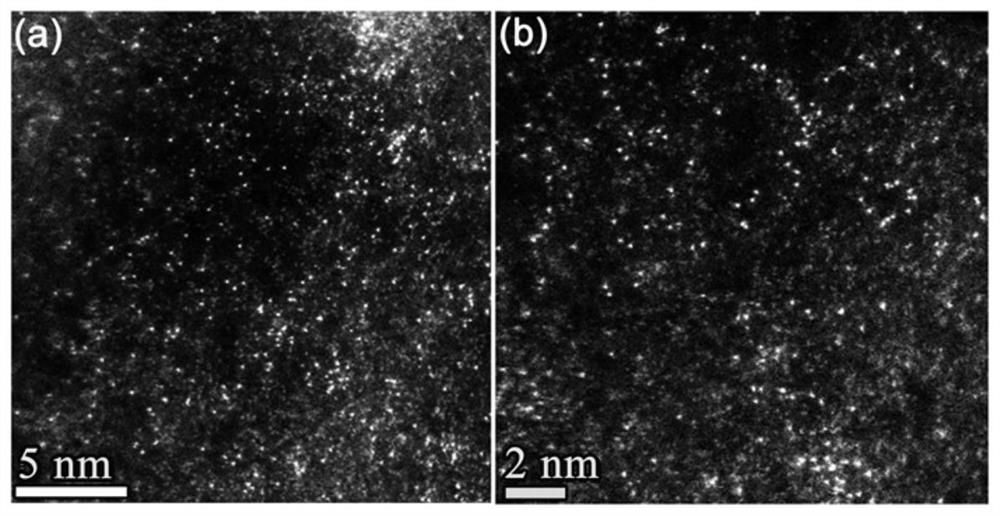

[0044] Example 2 0.2% Pt 1 Preparation of @TpPa-1-COF Photocatalyst

[0045] Weigh 434.8mg (ie 5mmol) of p-toluenesulfonic acid and 48.6mg (ie 0.9mmol) of p-phenylenediamine, grind for 5min, weigh 64.9mg (ie 0.6mmol) of 1,3,5-trialdehyde-based m-benzene Trisphenol, triturated for 10min, will contain 9.5µL, 100mg•mL -1 H 2 PtCl 6 The solution was diluted to 100µL, added dropwise, and continued to grind to obtain an orange mud; transferred to a watch glass, and reacted at 170 °C for 6 min to obtain a dark red product, which was cooled to room temperature and treated with N,N-dimethylacetamide. , deionized water and acetone were washed twice each in turn, and the product was dried in a blast drying oven at 60°C overnight; fully ground for 20-30min, then kept at 125°C for 1 hour under the protection of high-purity Ar, and cooled to room temperature with the furnace , get dark red Pt 1 The @TpPa-1-COF photocatalyst, in which the loading of single-atom Pt is 0.2 wt%.

Embodiment 3

[0046] Example 3 0.5% Pt 1 Preparation of @TpPa-1-COF Photocatalyst

[0047] Weigh 434.8 mg (i.e. 5 mmol) of p-toluenesulfonic acid and 48.6 mg (i.e. 0.9 mmol) of p-phenylenediamine, grind for 5min, weigh 64.9 mg (i.e. 0.6 mmol) of 1,3,5-trialdehyde m-benzene Trisphenol, triturated for 10 min, will contain 23.9 µL, 100 mg•mL -1 H 2 PtCl 6 The solution was diluted to 100 µL, added dropwise, and continued to grind to obtain an orange slurry; transferred to a watch glass and reacted at 170 °C for 6 min to obtain a dark red product, which was cooled to room temperature and treated with N,N-dimethylethyl acetate. Amide, deionized water, and acetone were washed twice each in turn, and the product was dried in a blast drying oven at 60°C overnight; fully ground for 20-30min, then kept at 125°C for 1 hour under the protection of high-purity Ar, and cooled with the furnace to room temperature to obtain dark red Pt 1 The @TpPa-1-COF photocatalyst with single-atom Pt loading of 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com