A Visible Light-Driven Microalgae Electrolysis Cell Splitting Water to Produce Hydrogen

An electrolysis battery and visible light technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of complex and expensive protein separation and stabilization technology, restriction of electron transfer efficiency, serious diffusion restriction, etc., to reduce the diffusion distance and reduce the cost of recombination Risk, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0034] Two embodiments of the present invention are described in detail below.

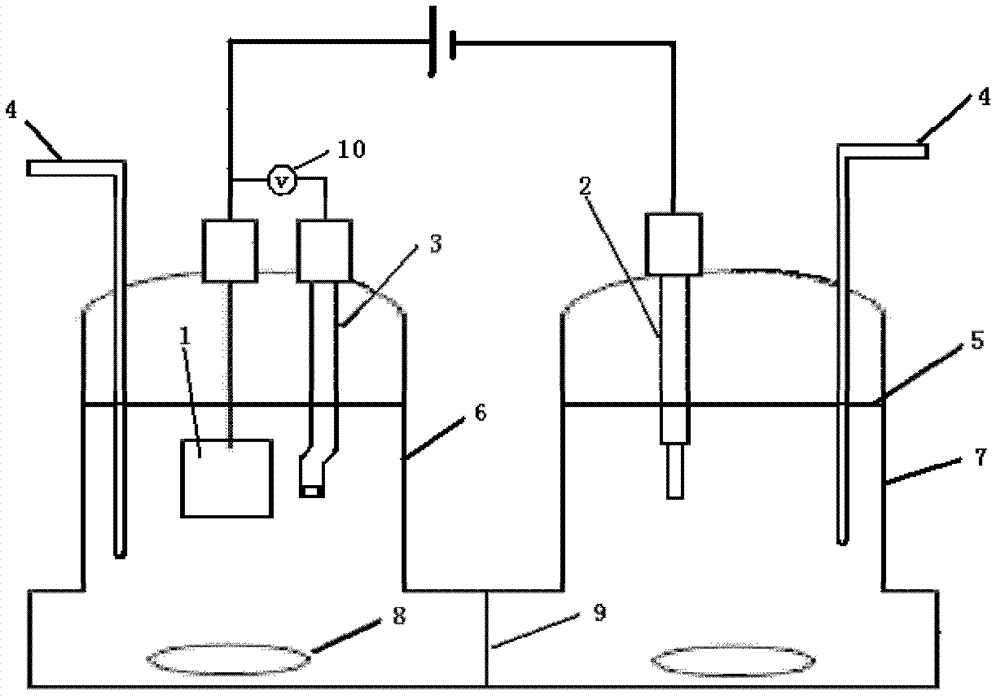

[0035] Such as figure 2 As shown, the microalgae electrolysis cell includes an anode chamber and a cathode chamber. The anode chamber and the cathode chamber are connected in a liquid phase at the bottom, and the upper and middle parts are separated by a gas separator to collect the released oxygen and hydrogen separately, without the need for hydrogen and oxygen separation; A proton exchange membrane or a porous plate is arranged as a separator at the direct connection between the anode chamber and the cathode chamber bottom of the microalgae electrolysis cell.

[0036] The described visible light-driven microalgae electrolysis cell decomposes water to produce hydrogen, uses the microalgae bioelectrode as the photoanode, constitutes a three-electrode system with the cathode and the reference electrode, and adds an electron mediator to the electrolytic cell solution to perform oxygen release and ...

Embodiment 1

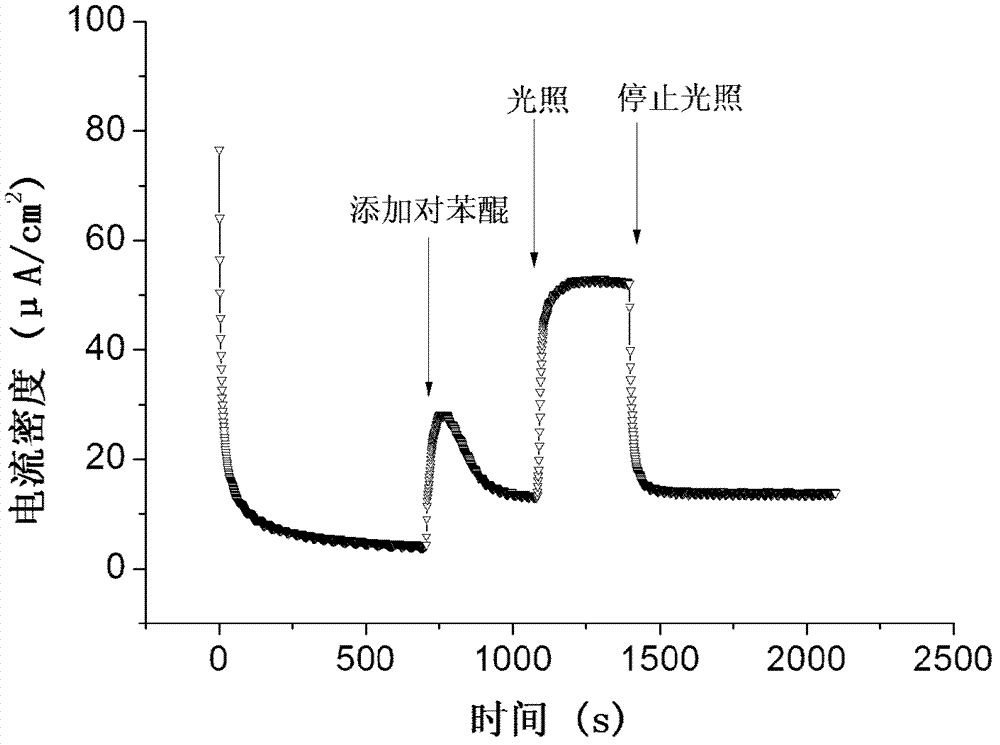

[0043] Photoresponse of Subcardioid Tetraspermum Photoelectrode to Light

[0044](1) Preparation of silica sol: slowly drop 10mL tetraethoxysilane into a stirring system of 60mL water and 30mL 0.01M HCl, react for 50h, adjust the pH to 7.50 with 1M NaOH solution, then react for 48h, the silica sol The pH is 7.81, and the prepared silica sol is ready for use.

[0045] (2) In the late logarithmic period of growth, the concentration is about 3.50×10 6 cells / mL of 57 mL of Tetraspermum subcardiac, concentrated by centrifugation at 2000 r / min for 1 min, and after discarding the supernatant, the algal cells were obtained. The algal cells obtained by centrifugation were resuspended in 2 mL of silica sol, the volume of the algae-silica sol mixture was pipetted to 50 μL, and air-dried to prepare a green algae bioelectrode.

[0046] (3) In the three-electrode system, the anode is a bioelectrode of green algae, the cathode is a platinum electrode or a titanium electrode, the reference ...

Embodiment 2

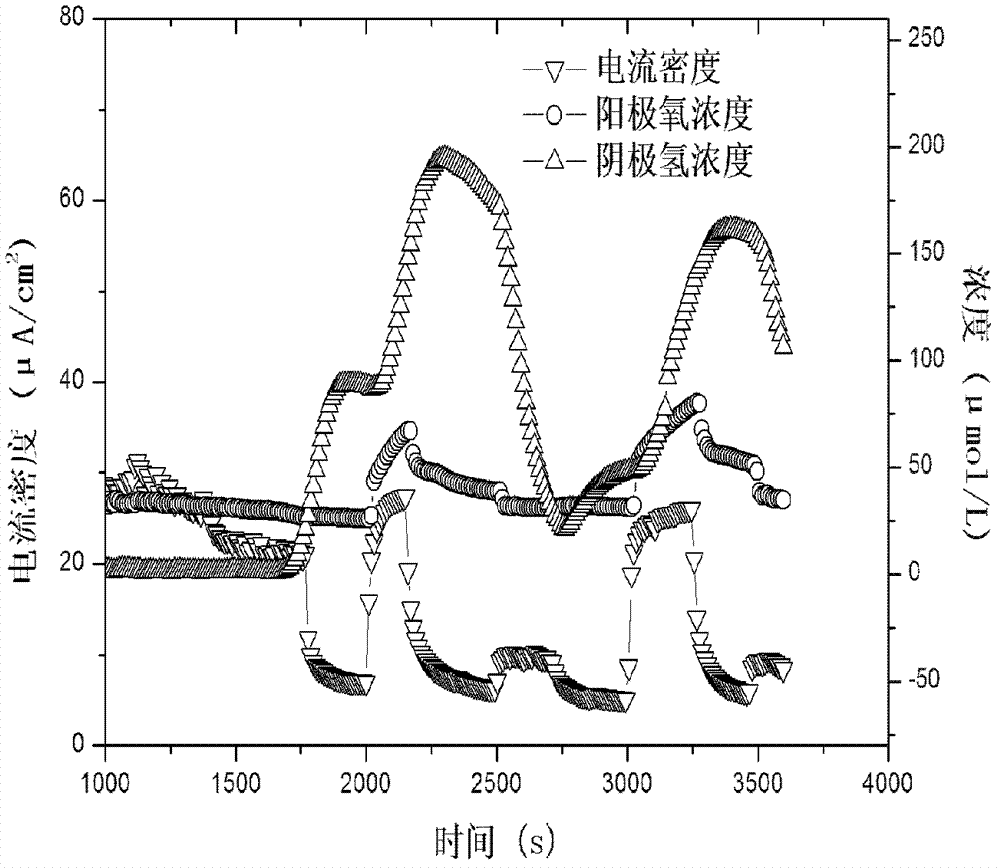

[0049] Visible light-driven microalgae electrolysis cell decomposes water to release hydrogen and oxygen

[0050] (1) Preparation of silica sol: slowly drop 10mL tetraethoxysilane into a stirring system of 60mL water and 30mL 0.01M HCl, react for 48h, adjust the pH to 7.49 with 1M NaOH solution, and then react for 4 days, the silica sol The pH is 8.0, and the prepared silica sol is ready for use.

[0051] (2) Take the concentration of about 2.64×10 6 38mL of cells / mL Tetraspermia subcardiac, Fv / Fm=0.754, yield=0.606 of the algal cells, concentrated by centrifugation at 2000r / min for 1min, and poured off the supernatant, the algal cells were obtained. The algal cells obtained by centrifugation were resuspended in 1 mL of silica sol, and the volume of the algae-silica sol mixture was pipetted to 50 μL, and air-dried to prepare a green algae bioelectrode.

[0052] (3) In the three-electrode system, the anode is a bioelectrode of green algae, the cathode is a platinum electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com