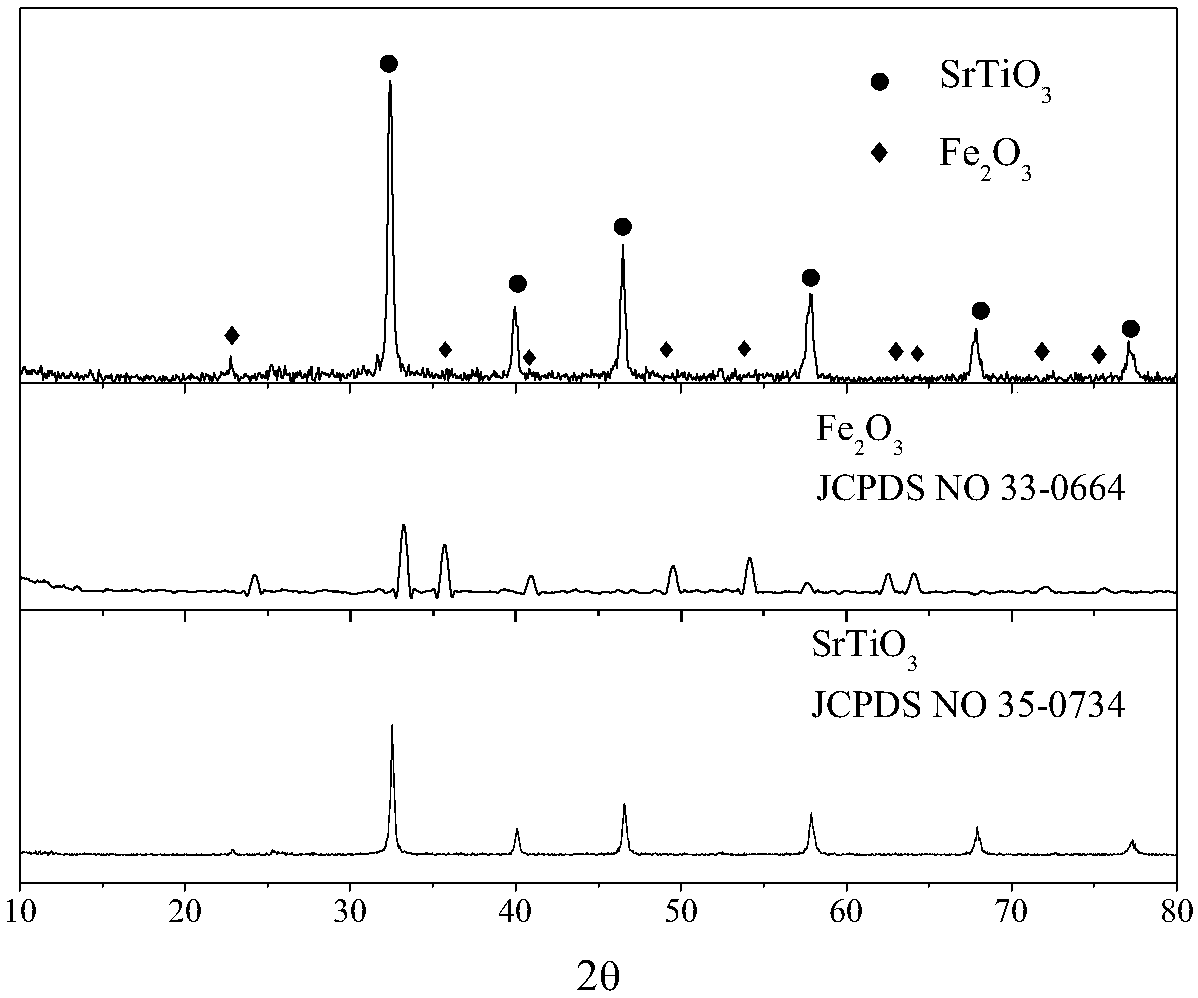

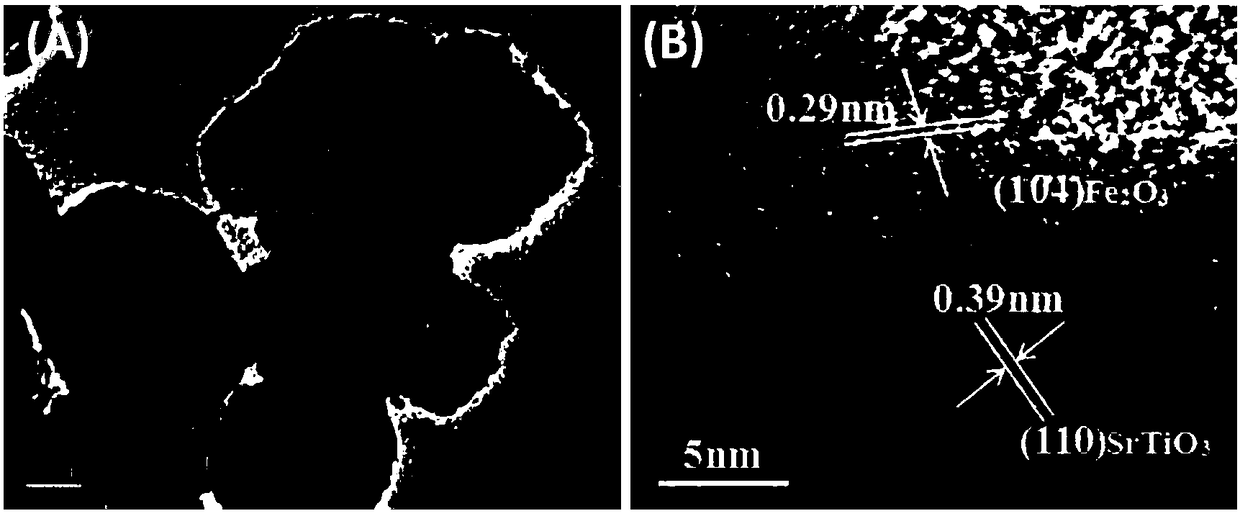

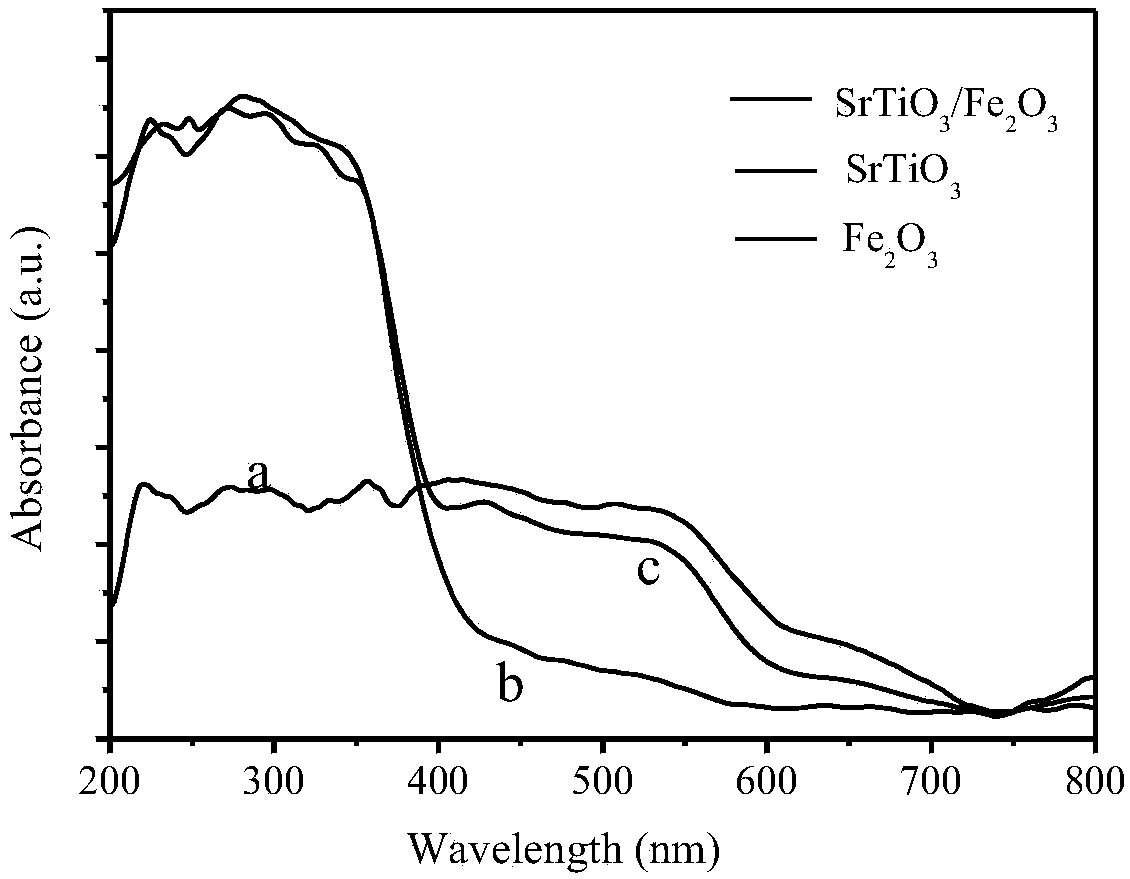

Application of SrTiO3/Fe2O3 in hydrogen production through water photolysis

A technology for producing hydrogen and fe2o3 from water, which is applied in the production of metal/metal oxide/metal hydroxide catalysts, hydrogen, hydrogen, etc., can solve the problems of low separation efficiency of photogenerated charges and unsatisfactory utilization of visible light, and achieve good results UV-Vis absorbing ability, low cost, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040]Further, the present invention provides one of the SrTiO 3 / Fe 2 O 3 The preparation method embodiment of , the concrete steps are as follows:

[0041] 1) The nanomaterial SrTiO 3 Disperse in ethanol solution and carry out ultrasonic dispersion treatment;

[0042] 2) adding a reducing agent to the above-mentioned dispersed solution, and ultrasonically reducing the high oxidation state of the reactant surface;

[0043] 3) Add nanoscale Fe to the solution after reduction 2 O 3 SrTiO is obtained by ultrasonication to make the reaction fully proceed, and then the reactant is centrifuged, washed and dried to obtain SrTiO 3 / Fe 2 O 3 ;

[0044] Wherein, in the step 1), SrTiO 3 The concentration configuration in ethanol solution is 0.1mg / ml; ultrasonic treatment conditions are: ultrasonic power 50W, ultrasonic 10min;

[0045] In described step 2), the reducing agent is sodium amalgam or sodium borohydride, more preferably sodium amalgam; ultrasonic treatment conditio...

Embodiment 1

[0063] (1) SrTiO 3 / Fe 2 O 3 2 mg of the composite material was dispersed and dissolved in 8 mL of purified water and 2 mL of methanol solution, and sealed in a 20-mL quartz bottle.

[0064] (2) ultrasonicate the solution in step (1) for 6 minutes at an ultrasonic power of 50W, so that the sample is uniformly dispersed in the solution; after the ultrasonic dispersion is completed, vacuumize the solution with a suction filtration pump, and the suction filtration time is 7 minutes; The solution is filled with nitrogen, the nitrogen pressure is 0.5Pa, the complete inflation time is 30s, and the charge-discharge balance time is 90s to ensure the balance of internal and external pressures.

[0065] (3) The above-mentioned quartz bottle containing the solution was installed in a photocatalytic reactor, irradiated under a 400W high-pressure mercury lamp, and the hydrogen production amount and rate were tested and compared after 6h of continuous irradiation respectively. SrTiO 3 / ...

Embodiment 2

[0067] (1) SrTiO 3 / Fe 2 O 3 2 mg of the composite material was dispersed and dissolved in 8 mL of purified water and 2 mL of EDTA-Na solution, and sealed in a 20 mL quartz bottle.

[0068] (2) ultrasonicate the solution in step (1) for 6 minutes at an ultrasonic power of 50W, so that the sample is uniformly dispersed in the solution; after the ultrasonic dispersion is completed, vacuumize the solution with a suction filtration pump, and the suction filtration time is 7 minutes; The solution is filled with nitrogen, the nitrogen pressure is 0.5Pa, the complete inflation time is 30s, and the charge-discharge balance time is 90s to ensure the balance of internal and external pressures.

[0069] (3) The above-mentioned quartz bottle containing the solution was installed in a photocatalytic reactor, irradiated under a 400W high-pressure mercury lamp, and the hydrogen production amount and rate were tested and compared after 6h of continuous irradiation respectively. SrTiO 3 / F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com