Method for synthesizing nanometer LiFePO4 lithium ion power battery cathode material by ferric iron source

A trivalent iron source and power battery technology, applied in the direction of battery electrodes, electrode manufacturing, chemical instruments and methods, etc., can solve the problems of poor product form, poor electrochemical performance, small production batches, etc., and achieve low manufacturing costs , Synthetic reaction time is shortened, and the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

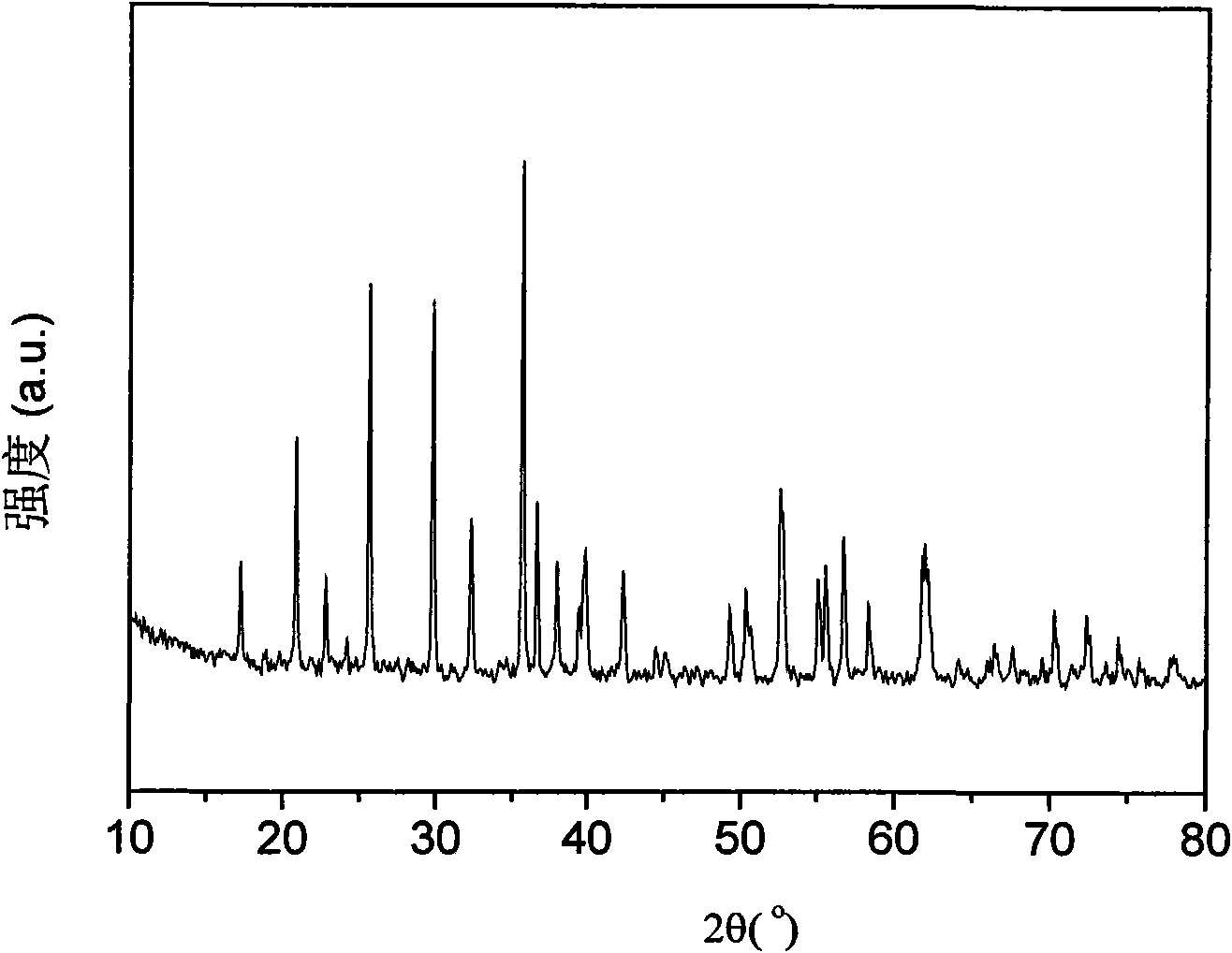

Embodiment 1

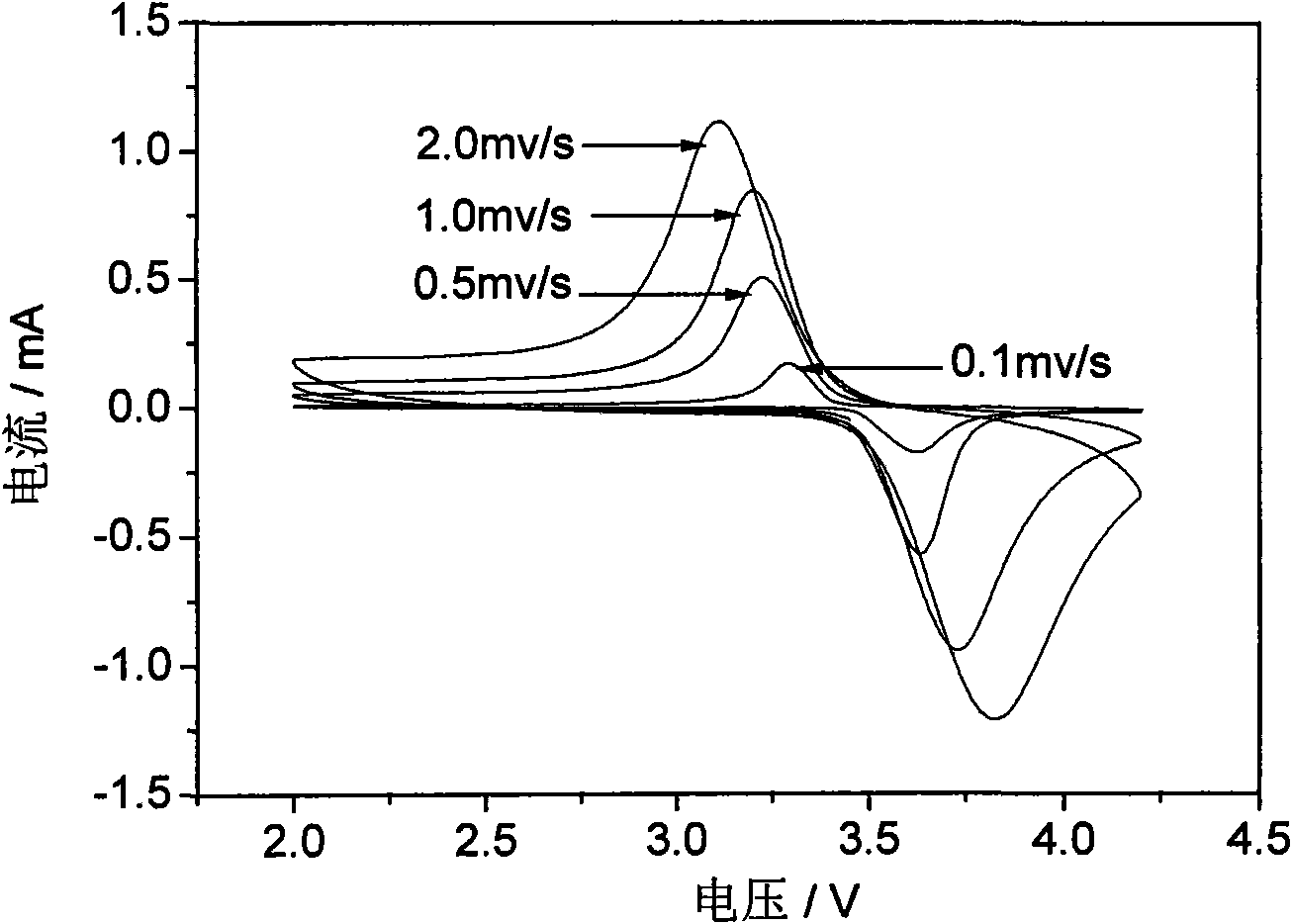

[0027] First, dissolve 0.1 mol lithium nitrate, 0.1 mol iron nitrate, and 0.1 mol ammonium dihydrogen phosphate (the required weight can be calculated by the number of moles × molecular weight) in deionized water, then add 60 g of glycine, heat and stir until a gel is formed . Then put the gel into an oven at 250°C to let it ignite spontaneously to obtain the precursor. Then the precursor was mixed with sucrose ball mill for 30 minutes, and finally the mixture was roasted at 800°C for 10 hours at a rate of 10°C / min in a nitrogen atmosphere to obtain the required LiFePO 4 / C material.

[0028] The prepared sample, conductive agent (SuperP), and binder (PVDF) were uniformly mixed in a mass ratio of 85:8:7, and coated on an aluminum foil with a thickness of 10 μm. After punching, the electrode sheets were dried in a vacuum oven at 100°C for 12 hours. The pure metal lithium sheet is used as the counter electrode, and the electrolyte is 1mol / L LiPF 6 , assembled into a mock bat...

Embodiment 2

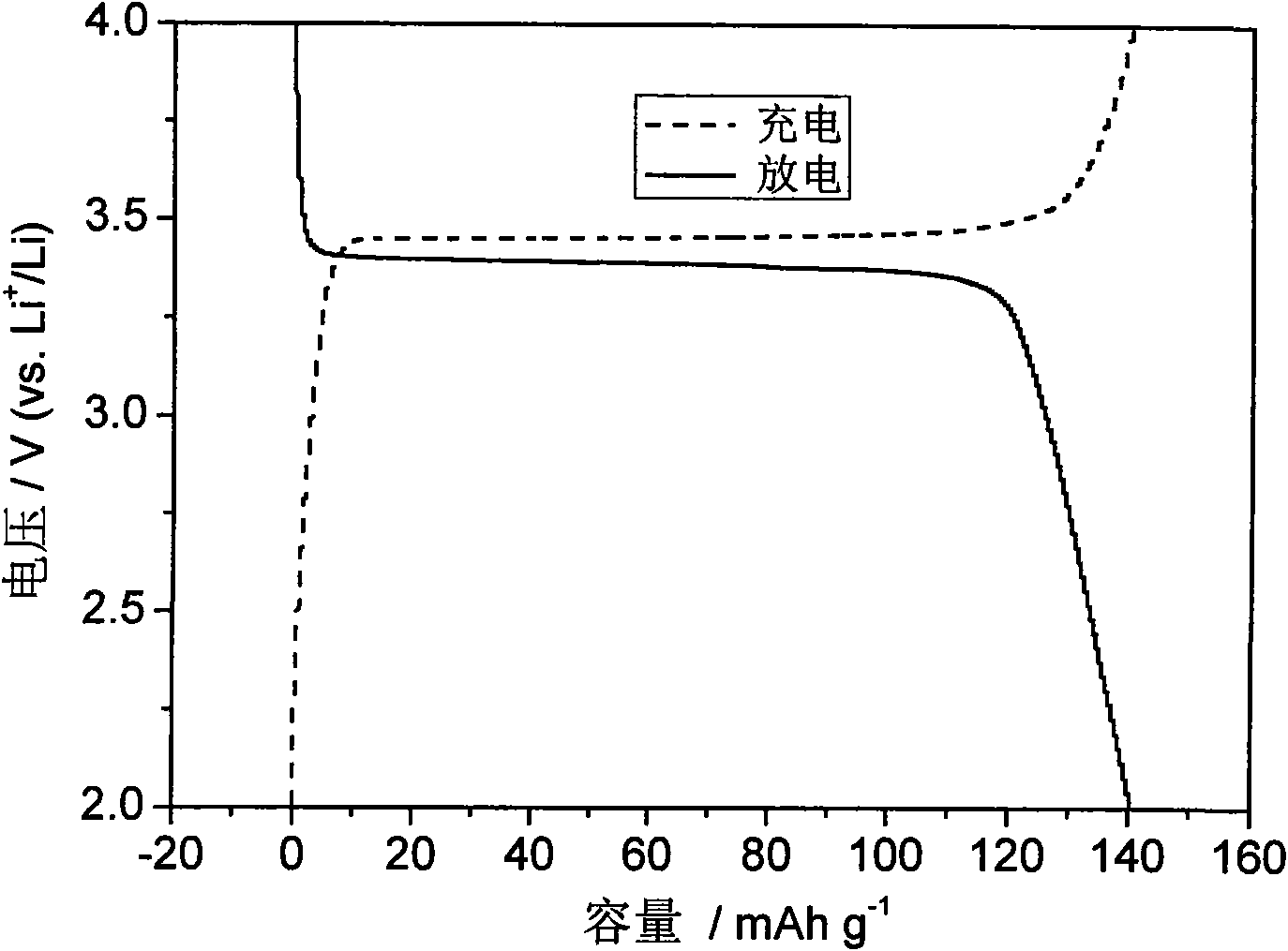

[0032] Mix the precursor and sucrose in Example 1 by ball milling for 2 hours, then heat up to 700°C for 20 hours in an argon atmosphere at a rate of 5°C / min to obtain the required LiFePO 4 / C material. The preparation of the simulated battery is consistent with the method in Example 1. Investigate the cycle performance of charging and discharging electrodes on a high-precision battery tester.

[0033] Such as image 3 Shown: Synthetic product LiFePO 4 The / C cathode material is assembled with Li to form a simulated battery. The specific capacity of the first discharge at 0.1C can reach 140mAh / g. The charging and discharging platform is flat and has good lithium intercalation performance.

[0034] Such as Figure 4 Shown: Synthetic product LiFePO 4 The / C cathode material is assembled with Li to simulate a battery with considerable capacity when it is charged and discharged stably at a high current. 5C stable charge and discharge reversible capacity reaches 94mAh / g; 10C ...

Embodiment 3 Embodiment 6

[0039]

[0040] The corresponding LiFePO can be obtained by referring to the method of Example 1 according to the above experimental parameters. 4 / C cathode active material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com