Chlorinated rubber prepared by utilizing recycled tire desulfurized rubber

A technology for recycling tires and devulcanized rubber, applied in the field of chlorinated rubber, to achieve the effects of reducing energy consumption, good economic benefits, and saving waste water treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

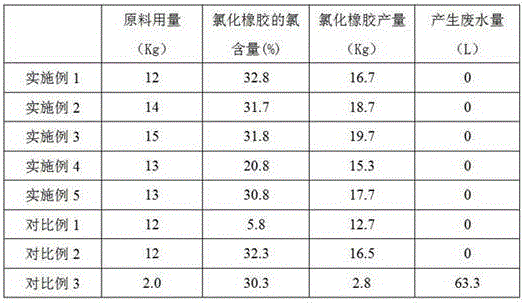

Examples

preparation example Construction

[0026] The concrete steps of preparation method are:

[0027] In a 100L titanium alloy stainless steel reaction kettle, add dilute hydrochloric acid with a concentration of 10-15wt%, rubber powder after desulfurization treatment of recycled tires, and stir to make them evenly mixed; The valve for entering liquid chlorine gas is gradually fed into liquid chlorine gas, and the temperature is raised. Before the temperature in the reactor reaches a constant temperature, control the pressure of chlorine gas at 0.35-0.50 MPa, add 40-60% of the formula amount of chlorine gas, and feed the remaining chlorine gas in the constant temperature reaction stage. , the constant temperature reaction stage controls the chlorine pressure at 0.65-0.85 MPa; the constant temperature is any point temperature of 100-130°C; the continuation of the reaction time after reaching the constant temperature reaction stage is 0.5-1.5h; the reaction is carried out under stirring; After the tail gas treatment d...

Embodiment 1

[0032] In a 100L titanium alloy stainless steel reaction kettle, add 50L of dilute hydrochloric acid with a concentration of 13wt%, 12Kg of rubber powder after tire desulfurization treatment, and stir to make them evenly mixed; methyl ammonium chloride 0.08Kg, initiator BPO (dibenzoyl peroxide) 0.015Kg, stir and heat for 0.5h, when the temperature reaches 80°C, start to introduce 0.40 MPa of chlorine gas, control the amount of chlorine gas and gradually Raise the temperature to 115°C and maintain a constant temperature. The amount of chlorine in the early stage is 2.4Kg, the amount of chlorine in the constant temperature stage is 3.5Kg, the pressure of chlorine gas in the constant temperature stage is 0.70 MPa, and the time for chlorine gas in the constant temperature stage is 0.5 h; Keep the temperature and continue to react for 0.8h, and the reaction is over; after using the tail gas treatment device to absorb the chlorine gas in the reactor, the product is deacidified by cen...

Embodiment 2

[0034] In the 100L titanium alloy stainless steel reaction kettle, add 55L of dilute hydrochloric acid with a concentration of 11wt%, 14Kg of rubber powder after tire desulfurization treatment, and stir to make it evenly mixed; add lignin derivative dispersant 0.085Kg, emulsifier 16 Alkyltrimethylammonium chloride 0.08Kg, initiator di-tert-butyl peroxide DTBP 0.015Kg, stir and heat for 0.5h, when the temperature reaches 85°C, start to feed 0.45 MPa of chlorine gas, control the amount of chlorine gas and Gradually raise the temperature to 115°C and maintain a constant temperature. The amount of chlorine in the early stage is 3.0Kg, the amount of chlorine in the constant temperature stage is 3.9Kg, the pressure of chlorine gas in the constant temperature stage is 0.75 MPa, and the time for chlorine gas in the constant temperature stage is 0.5 h; , keep the temperature and continue to react for 1.0 h, and the reaction ends; after the chlorine gas in the reactor is absorbed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com