Preparation method of biodegradable nasal hemostatic sponge

A technology of hemostatic sponge and nasal cavity, which is applied in medical science, absorbent pads, bandages, etc., to achieve the effects of low production cost, easy-to-obtain raw materials, and simple and easy operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

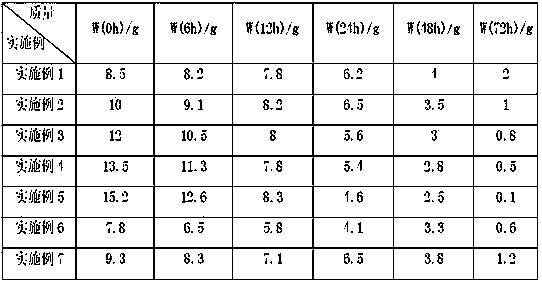

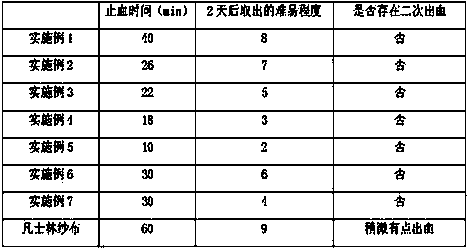

Examples

Embodiment 1

[0040] (1) Synthesis of chain extender: Take 90g of hexamethylene diisocyanate (HDI) and place it in a reaction bottle, and make the molar ratio to HDI (n BDO : n HDI = 1:14) of 1,4-butanediol (BDO) was slowly added dropwise to HDI, stirred and reacted at 80°C for 3 hours, the reaction system was cooled to room temperature, and purified by adding n-hexane to obtain a chain extender, which was characterized by NMR The product has been purified;

[0041](2) Synthesis of block prepolymer: put PEG 600 / L-lactide / caprolactone by mass (35g / 25g / 25g) in a reaction flask, add 200 μL of catalyst stannous octoate, and heat to 140°C under vacuum , reacted for 24 hours to obtain the desired block prepolymer;

[0042] (3) Synthesis of biomedical polyurethane: Dissolve 25g of the chain extender prepared in step (1) with DMSO, and the molar ratio to the block prepolymer is 1:1, after the block prepolymer in step (2) is prepared , remove the vacuum, maintain normal pressure, and lower the te...

Embodiment 2

[0045] (1) (2) Synthesize chain extender and block prepolymer according to the method in Example 1;

[0046] (3) Synthesis of biomedical polyurethane: Dissolve 2.8g of hexamethylene diisocyanate (HDI) and 17.6g of the prepared chain extender in DMSO, the molar ratio between the two is 0.4: 1, the molar number of the two The molar ratio of the sum to the block prepolymer is 1:1, and it is ready for use; after the block prepolymer is prepared, remove the vacuum, maintain normal pressure, and cool the reaction system to 80°C, slowly dissolve the dissolved DMSO solution Add it dropwise into the block prepolymer system, stir, and react for 2.5 hours. The reaction system becomes viscous. Dilute it with an appropriate amount of DMSO, and then repeatedly settle with water and ethanol to obtain the required polybiomedical polyurethane.

[0047] (3) Preparation of hemostatic sponge: Dissolve 5g of the biomedical polyurethane synthesized above into 1,4-dioxane to form 100g of a 5% soluti...

Embodiment 3

[0049] (1) (2) Synthesize chain extender and block prepolymer according to the method in Example 1;

[0050] (3) Synthesis of biomedical polyurethane: Dissolve 4.3g of hexamethylene diisocyanate (HDI) and 13.7g of the prepared chain extender in DMSO, the molar ratio between the two is 0.8: 1, the molar number of the two The molar ratio of the sum to the block prepolymer is 1:1, and it is ready for use; after the block prepolymer is prepared, remove the vacuum, maintain normal pressure, and cool the reaction system to 80°C, slowly dissolve the dissolved DMSO solution Add it dropwise into the block prepolymer system, stir, and react for 2 hours. The reaction system becomes viscous. Dilute it with an appropriate amount of DMSO, and then repeatedly settle with water and ethanol to obtain the desired biomedical polyurethane.

[0051] (4) Preparation of hemostatic sponge: Dissolve 6g of the biomedical polyurethane synthesized above into 1,4-dioxane to form 100g of a 6% solution, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com