Purification system and method for flue gas in continuous feeding electric-arc furnace

A flue gas purification system and flue gas purification technology are applied in the field of flue gas purification to achieve the effects of shortening the synthesis reaction time, helping to protect the environment, and reducing the production of toxic and carcinogenic dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

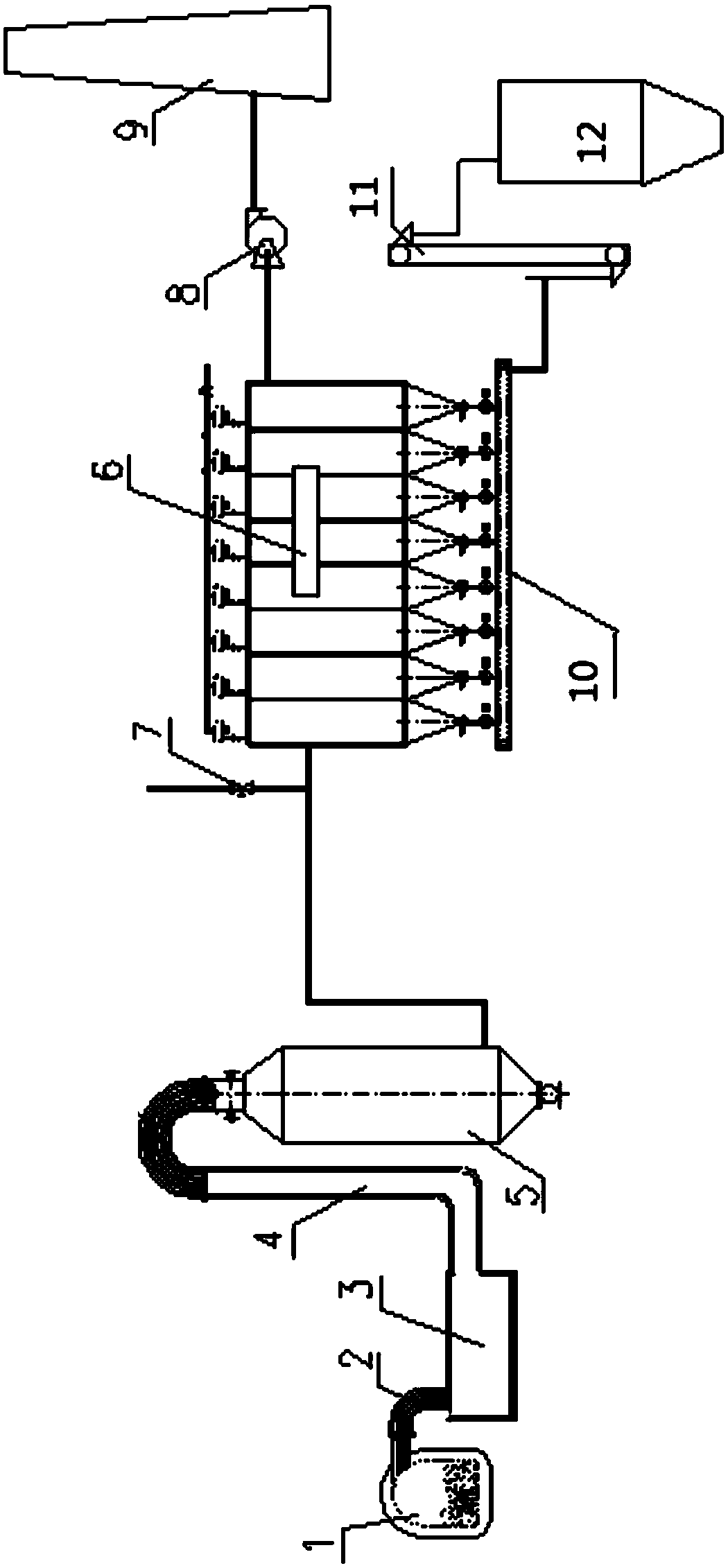

[0026] The temperature at the exhaust outlet 1 of the scrap steel preheating section is 700°C. The high-temperature flue gas enters the settling chamber 3 through the water-cooled elbow 2 for pre-settling dust removal, and then enters the evaporative cooling tower 5 through the heat preservation flue 4, and the heat preservation flue 4 The dioxin toxic carcinogens in the flue gas are basically decomposed and destroyed, and the evaporative cooling tower 5 is rapidly cooled to 200°C at a rate of 200°C / s to shorten the synthesis reaction time of the dioxin toxic carcinogens in the flue gas, that is, Reduce the production of toxic and carcinogenic dioxins. The rapidly cooled flue gas enters the bag filter 6 for fine dust removal. The final flue gas temperature is 76°C and the dust concentration is 8.2mg / Nm 3 , containing dioxin 0.38mg / Nm 3 , up to emission standards.

Embodiment 2

[0028] The temperature at the exhaust port 1 of the scrap steel preheating section is 900°C, and the high-temperature flue gas enters the settling chamber 3 through the water-cooled elbow 2 for pre-settling dust removal, and then enters the evaporative cooling tower 5 through the heat preservation flue 4, and the heat preservation flue 4 The dioxin toxic carcinogens in the flue gas are basically decomposed and destroyed, and the evaporative cooling tower 5 is rapidly cooled to 210°C at a rate of 300°C / s to shorten the synthesis reaction time of the dioxin toxic carcinogens in the flue gas, that is, Reduce the production of toxic and carcinogenic dioxins. The flue gas after rapid cooling enters the bag filter 6 for fine dust removal. The final flue gas temperature is 79°C and the dust concentration is 8.9mg / Nm 3 , containing dioxin toxic carcinogen 0.42mg / Nm 3 , up to emission standards.

Embodiment 3

[0030] The temperature at the exhaust outlet 1 of the scrap steel preheating section is 1000°C. The high-temperature flue gas enters the settling chamber 3 through the water-cooled elbow 2 for pre-settling dust removal, and then enters the evaporative cooling tower 5 through the heat preservation flue 4, and the heat preservation flue 4 The dioxin toxic carcinogens in the flue gas are basically decomposed and destroyed, and the evaporative cooling tower 5 is rapidly cooled to 228°C at a rate of 400°C / s to shorten the synthesis reaction time of the dioxin toxic carcinogens in the flue gas, that is, Reduce the production of toxic and carcinogenic dioxins. After rapid cooling, the flue gas enters the bag filter 6 for fine dust removal. The final flue gas temperature is 83°C and the dust concentration is 8.6mg / Nm 3 , containing dioxin toxic carcinogen 0.41mg / Nm 3 , up to emission standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com