Sodium hydrosulfite synthesizing and continuous producing method

A production method and technology of hydrosulfite, which is applied in the field of continuous production of hydrosulfite synthesis, can solve problems such as non-continuous, etc., and achieve the effects of improving production efficiency, improving efficiency, and balancing exhaust gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

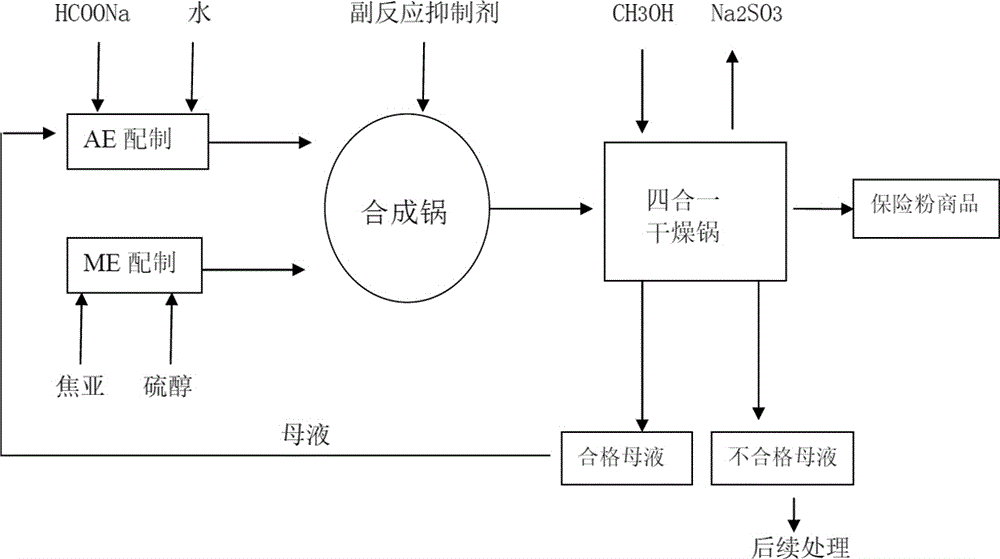

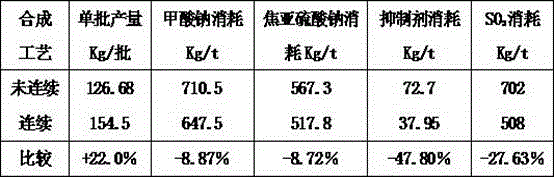

Method used

Image

Examples

Embodiment 1

[0047] Getting the raw materials ready: the configuration mass fraction is 98% HCOONa, and the preparation mass fraction is 62% sodium pyrosulfite concentration with SO 2 Gauge, SO 2 -CH 3 OH,SO 2 Concentration ≥ 370g / L, carrier methanol, mass fraction is 78%;

[0048] Bottom feeding: use inert gas to press into the storage tank, open the flow meter and feed AE of about 1.8m³ into the synthetic large dripping pot, and start to heat up;

[0049] Value adjustment: Turn on the steam when the temperature rises to 76°C, the pressure is at 0.1MPa, and at the same time open the flow meter valve to add SO to the large dripping pot 2 -CH 3 OH solution 25L, a certain amount of ethylene oxide, and adjust the pH to 4.3;

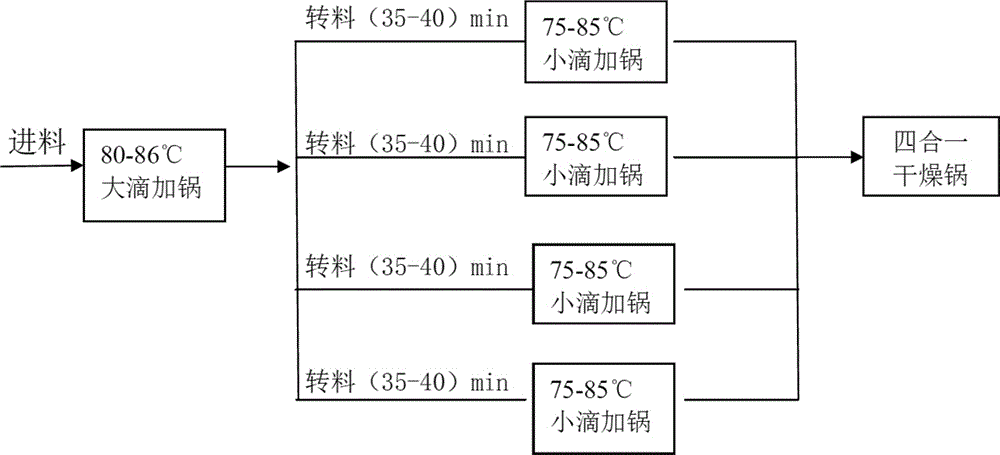

[0050] Large dripping: After adjusting the value for 10min~20min, when the temperature rises to 81℃~82℃, start adding AE and ME to stabilize the pH at 4.4~4.5, and the pressure is 0.2MPa~0.25MPa. After reaching 80% (one batch of materials), the bottom tubes in the ...

Embodiment 2

[0055] Getting the raw materials ready: the configuration mass fraction is 99% HCOONa, and the preparation mass fraction is 64% sodium metabisulfite concentration (in the form of SO 2 Count), SO 2 -CH 3 OH,SO 2 Concentration ≥ 370g / L, carrier methanol, mass fraction is 79%;

[0056] Bottom feeding: use inert gas to press into the storage tank, open the flow meter and feed about 2m³ of AE to the synthetic large dripping pot, and start to heat up;

[0057] Value adjustment: Turn on the steam when the temperature rises to 80°C, the pressure is between 0.15MPa and 0.2MPa, and at the same time open the flow meter valve to add SO to the large dripping pot 2 -CH 3 OH solution 25L, a certain amount of ethylene oxide, and adjust the pH to 4.4;

[0058] Large drop: After adjusting the value for 10min~20min, when the temperature rises to 82°C~83°C, start adding AE and ME to stabilize the pH at 4.3~4.4, and the pressure is 0.15MPa~0.2MPa. After reaching 80% (one batch of materials),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com