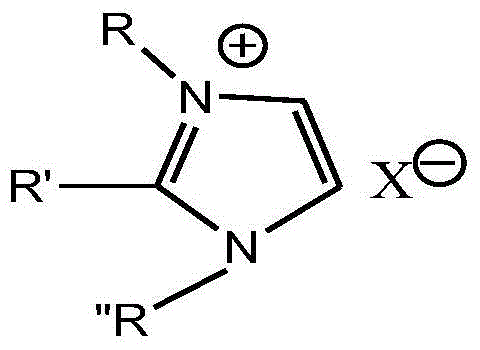

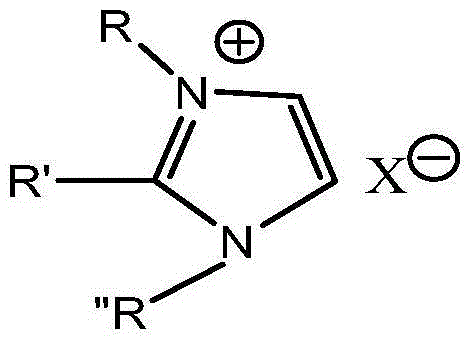

Imidazolium ionic liquid, application thereof and preparation method of 2, 5-azodicarboxylic acid diethyl ester-3, 4-ethylenedioxythiophene

A technology of diethyl dicarboxylate and dioxyethylene thiophene, which is applied in the field of preparation of imidazole ionic liquids, 2,5-diethyl dicarboxylate-3,4-dioxyethylene thiophene, can solve the problem of Problems such as high cost, unfavorable scale-up production, and difficulty in solvent recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

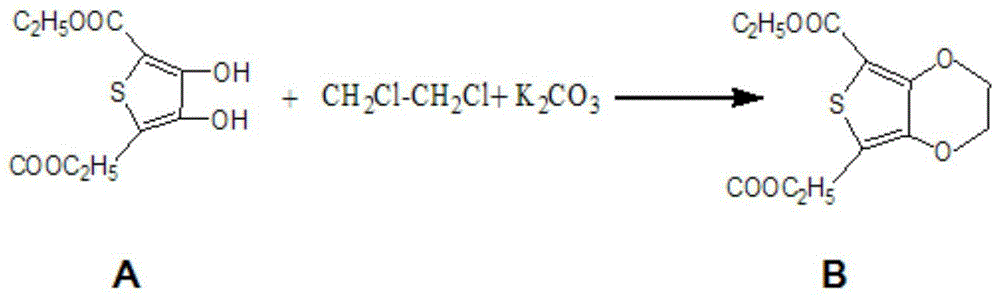

Embodiment 1

[0022] Add 117g 1-ethylimidazolium tributyl phosphate and 39g 2,5-dicarboxylate-3,4-dihydroxythiophene (raw material A in the reaction formula) in a 1L four-neck flask with stirring and a thermometer ), start stirring and wait for the powder to dissolve and slowly add 24.8g of anhydrous potassium carbonate, raise the temperature to 80°C, add half of dichloroethane 12.5g dropwise, after the drop is completed, raise the temperature to 110°C, add dropwise the remaining half of dichloroethane 12.5g g, after completion, the temperature was raised to 125° C. for 12 hours, and the reaction was stopped and the stirring was lowered to room temperature. The reaction solution was filtered, and 103.5 g of the filtrate was retained. The wet weight of the filter cake is 43g, add 100g of water to elute and filter to obtain 39g of product (wet weight), bake at 90°C to constant weight to obtain about 34.4g of product B in the reaction formula, the yield of this step is 80.2%, mp: 147~151 ℃. ...

Embodiment 2

[0025] Add 110g of 1-ethyl-3-methylimidazolium tetrafluoroborate and 35g of 2,5-dicarboxylate-3,4-dihydroxythiophene into a 1L four-neck flask with stirring and a thermometer ( For the raw material A) in the reaction formula, start stirring until the powder is completely dissolved, slowly add 24.8g of anhydrous potassium carbonate, raise the temperature to 80°C, add 12.5g of half of dichloroethane dropwise, after the drop is completed, raise the temperature to 110°C, add dropwise the remaining 12.5 g of half of dichloroethane, after completion, the temperature was raised to 125°C for 12 hours, and the reaction was stopped and the stirring was lowered to room temperature. The reaction solution was filtered, and 93.5 g of the filtrate was retained. The wet weight of the filter cake is 43g, add 100g of water to elute and filter to obtain 36.5g of product (wet weight), bake at 90°C to constant weight to obtain about 29.4g of product B in the reaction formula, the yield of this ste...

Embodiment 3

[0027] Add 120g 1-butyl-3-methylimidazolium hexafluorophosphate and 39g 2,5-dicarboxylate-3,4-dihydroxythiophene to a 1L four-neck flask with stirring and a thermometer (reaction For the raw material A) in the formula, start stirring and wait until the powder is dissolved, slowly add 24.8g of anhydrous potassium carbonate, raise the temperature to 80°C, add half of dichloroethane 12.5g dropwise, after the dropping, raise the temperature to 110°C, add the remaining half dropwise Dichloroethane 12.5g, after completion, the temperature was raised to 125°C for 12h, and the reaction was stopped and the stirring was lowered to room temperature. The reaction solution was filtered, and 109.2 g of the filtrate was retained. The wet weight of the filter cake is 46g, add 100g of water to elute and filter to obtain 37g of product (wet weight), bake at 90°C to constant weight to obtain about 31.8g of product B in the reaction formula, the yield of this step is 74.1%, mp: 143~149 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com