Flocculant and preparation method thereof

A coagulant and organic solvent technology, applied in the field of coagulant and its preparation, can solve the problems of harsh preparation conditions and increase the cost of rubber enterprises, and achieve the effect of fast powder formation and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 200g of polyperfluoroethylene propylene resin emulsion with a solid content of 30% and 50g of magnesium chloride aqueous solution with a mass percentage concentration of 30% into 200g of 95% ethanol, at room temperature, stirring at a speed of 200r / min, and fully mix to form a dispersion system .

Embodiment 2-7

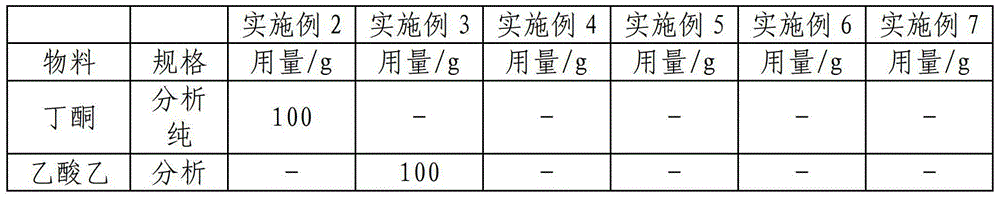

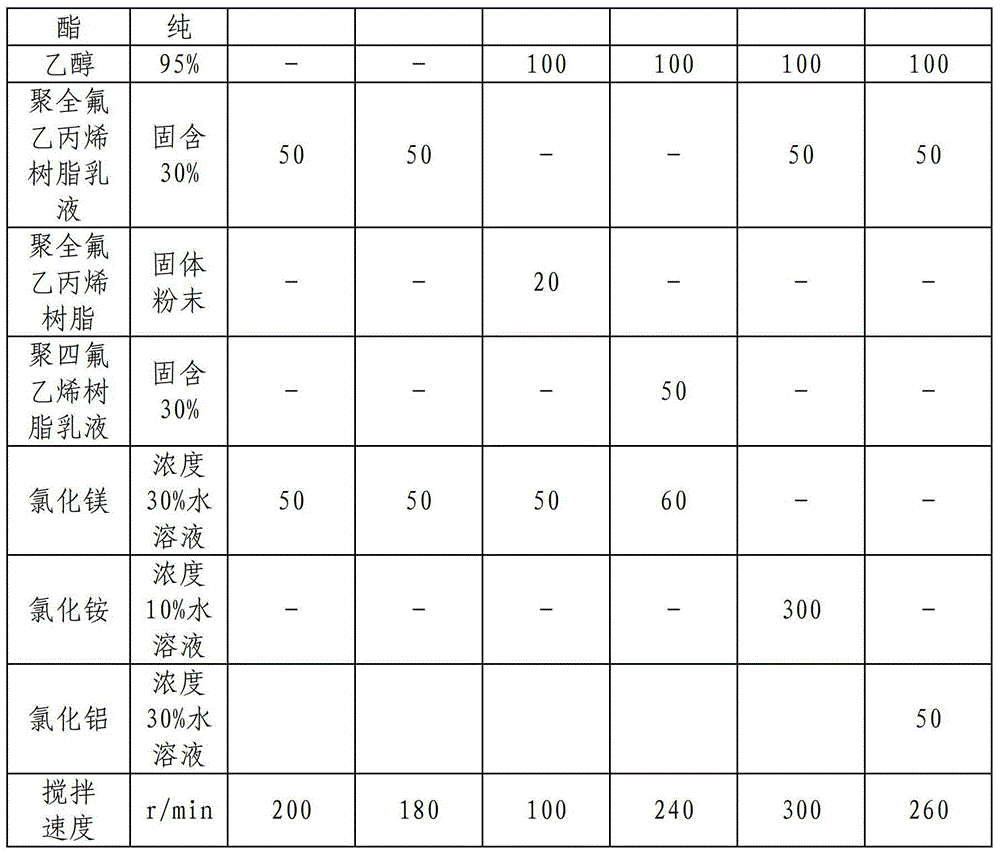

[0026] According to the ratio of each raw material in Table 1, the coagulant was prepared according to the method of Example 1.

[0027] Table 1 Coagulant Raw Material Ratio

[0028]

[0029]

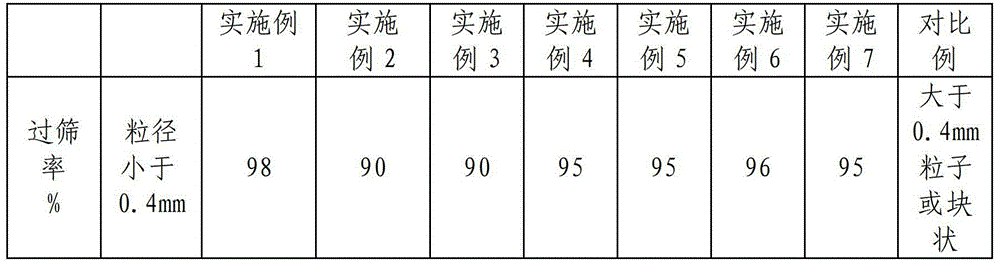

[0030] Preparation of powdered rubber

[0031] 1, utilize the coagulant of above-mentioned embodiment 1-7 gained to prepare powdered rubber, concrete preparation method is as follows:

[0032] Weigh 450 g of coagulant obtained in Example 1. Under stirring conditions, slowly add 1000g of fluororubber emulsion (30% dry rubber) to the coagulant at a rate of 200g / min. With the addition of the fluororubber emulsion, the fluororubber in the mixture is continuously coagulated and precipitated in the form of particles. The fluororubber particles and ethanol aqueous solution were separated by vacuum filtration, and the ethanol aqueous solution was recovered for reuse after treatment. The fluororubber particles were washed and dehydrated, and then dried in a vacuum oven at 55°C for 12 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com